Author: Fon_Enot

16 September 2021 19:28

Community: Crafts for beginners and masters

Tags: handmade lifehack girls lifehacks why handmade needlework handmade sewing

21111

4

Handmade is held in high esteem. More and more girls are trying to learn how to sew and are buying sewing machines. But at first, even an expensive and automated machine can stitch unevenly. This is frustrating and discourages the desire to become a craftswoman. Why can the machine make an uneven stitch?

0

The reason for skipping stitches with a sewing machine must be sought in one of three components:

- needle

- threads

- fabric Seamstresses who have been using the machine for a long time know the main reasons and can easily eliminate the defect. For beginning craftswomen, skipping a stitch can lead to a state where they want to give up everything and never sit down at the machine again. Don’t rush to despair - everything can be fixed.

How a stitch is formed

The operation of a sewing machine is possible due to high precision and synchronization of the movement of various parts. Here it is much more important than, for example, in a washing machine. When making stitches, two threads are used:

- The thread at the top that unwinds from the spool and passes through the eye of the needle.

- The one that unwinds from a bobbin located below the working surface of the machine.

The structure of a sewing machine

The shuttle is a part that rotates and hooks the thread coming out of the eye of the needle. To create a seam, this hook pulls the loop down, then the thread is pulled up and it catches the thread coming from the bobbin. The machine then starts a new stitch.

During these operations, the accuracy of movements and the relative position of the needle and shuttle are very important. It is also important to ensure that the tension of the upper and lower threads is correct: not too tight and not too loose. When creating a zigzag or other seam, the work occurs in a similar way.

You might be interested in this: Simple patterns and instructions for sewing high-waisted shorts

How does a stitch happen?

The role of the needle in the operation of a sewing machine

One of the reasons for skipped stitches is the needle. In order to troubleshoot the problem, you need to remove the needle and examine it carefully. The needle will have to be replaced if it is damaged. For example, during operation, the needle may become dull, bent, become jagged, and dirt may get into the groove. Do not try to repair damage using improvised means, as these actions will subsequently lead to more significant damage and malfunctions of the sewing machine.

If the inspection shows that the needle is in good condition, then you can try to reinsert it, securely fastening it and adjusting the height.

The reason for the appearance of gaps may be a mismatch of needle for the sewing machine model. There are three types of needles: universal, household and industrial. Never use industrial needles with a round bulb in household machines! Otherwise, the gap between the tip of the needle and the nose of the shuttle will increase at the moment the loop is caught, thereby forming a stitch skip. When purchasing new needles, pay attention to the markings.

The main reason for the appearance of gaps in a line

If a Janome or other sewing machine makes gaps in the stitching, then instead of a large number of stitches, a straight piece of thread is visible on the fabric. The main reason why this happens is that the hook of the shuttle, when moving down, cannot catch the thread coming from the eye of the needle. Skipping stitches in machine stitching happens if the seamstress does not pay attention to the defect in time. There can be various reasons for such a breakdown. In order to restore proper operation of the sewing machine, it is necessary to understand why the sewing machine skips stitches when sewing.

Bobbin

Why the upper thread does not catch the lower thread: what to do

In order for the nose of the shuttle to be able to catch the thread when moving downwards, the distance between them must be 0.3 mm. Anything larger or smaller will result in skipped stitches. This type of stitching defect can also occur for other reasons. The tension force for the upper and lower threads must be precisely set.

In the bobbin on the Brothers machine, there is a screw for this, which must be tightened in the desired direction. You can check the correct tension by holding the bobbin by the thread and shaking it slightly. At the same time, it should go down a little. If the bobbin is tensioned too tightly, it will not move, and if it is too weak, it will begin to unwind quickly.

Skipped stitches

The reason for the failure of the needle and hook settings: what to do

If all parts are installed accurately, the machine will make neat seams. However, over time, parts of the mechanism may shift, which can lead to operational problems.

The shuttle is a structure consisting of several parts. Some brands of cars (for example, Podolsk) use a plastic ring, which can lose its shape over time. To make it smooth again, you can use the following method:

- Prepare boiling water.

- Place the part in it for a few seconds.

- Remove and place on a clean piece of cloth.

- Place a cold iron against the side that needs to be leveled.

You may be interested in Pregnancy and sewing with a needle and thread: possible or not

As a result, the part will become even, and the shuttle offset will be correct, after which the machine will stop skipping stitches.

The needle must fit the sewing machine

Using special needles for sewing knitwear and leather

When skipping stitches occurs on a sewing machine, there can be different reasons. You also need to check the following: the needle matches the material. Sometimes difficulties arise with stitching certain types of fabrics (for example, suede, fur or leather); here it would be appropriate to use special numbers and shapes of needles.

Only in this case can the needle easily pierce knitwear or leather without tearing it. A needle specially adapted to work with this fabric will produce high-quality stitches and reduce the risk of missing stitches.

A poor-quality needle is a possible cause of malfunctions

A bent or dull needle causes skipped stitches

A bent needle also causes skipped stitches on your sewing machine. If the needle becomes slightly bent or dull, it should be replaced. Never trying to straighten the needle or sharpen it. The metal for sewing needles is of a special brand and it is impossible to straighten it perfectly. Make it a rule to change needles more often, even if there is no obvious need for it. This is especially important after prolonged use or when a dull knock occurs. This sound means that the “blunt” nose of the needle no longer pierces, but breaks through the tissue, which is why the characteristic sound appears.

Damaged needle: what to do

Sometimes the reason for skipping is the use of a low-quality or damaged needle. This can happen in a situation where it is bent and trying to pierce thick fabric. This bend may be completely invisible at first glance. Another cause of the problem may be a situation where the needle has become dull. This situation occurs most often when creating a multi-layer seam. The needle needs to be replaced with a more suitable one.

It is important to choose the right thread

Choosing the right needles: causes and solutions to the problem

The selection of thread matters for the quality of sewing. This is another reason why a sewing machine skips stitches. To use a specific needle, you need to take a thread of a certain thickness. Otherwise, it will move unpredictably while the sewing machine is running and will skip stitches. For example, a thick thread in a thin needle can quickly break. This is because it will have difficulty passing through the fabric.

You might be interested in this: Step-by-step instructions for sewing fabric bags

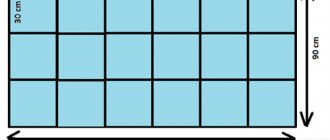

Needle plate

What other reasons could there be for skipping stitches?

In addition to common reasons for skipping stitches, there may be:

- Manufacturing defects. It is detected almost from the first days of operation. The only solution is to replace the sewing machine under warranty.

- Thread and needle mismatch. For example, thick threads and a thin needle.

- Heavily twisted thread.

- Heavy contamination and lack of lubrication.

- Damage to the shuttle assembly.

- Large hole in the needle plate.

One of the ways to quickly and efficiently fix the problem is to contact the ARS-Master repair shop. You can call a specialist to your home or address the problem directly to the center. Our technicians have extensive experience in repairing and servicing sewing machines from different manufacturers.

We know more about your car than you do!

Twisted thread: what to do

If a low-quality thread is used, it may behave unpredictably. The twisted one will begin to spontaneously curl into knots. If it is uneven in thickness, it will not allow it to pass through fleece or other fabric easily. Such a defect can cause incorrect loop formation when the needle moves.

When selecting by hand, you need to choose threads of uniform thickness, moderately elastic, and not twisted. You can, for example, use those made of polyester. The thickness should correspond to the needle used and the material with which the work is being done.

To stitch denim you need the right needle

If the sewing machine skips stitches, you need to make sure that the needle and threads are selected correctly, and that the shuttle and the needle are at a certain, clearly adjusted distance from each other. To correct the situation, you need to use high-quality parts and threads. It is important that they match the fabric with which you are working. If you can’t fix the car yourself, it makes sense to contact a specialist.

Determining the Source of the Problem

To find out the reason for the incorrect operation of the sewing machine, it is worth finding out the most common situations that can lead to this. It's better to start with the simplest ones.

Incorrect hardware setup

This reason is considered first, since if the problem is due to improper configuration, it is easiest to fix the problem. We are familiar with the principle of stitch formation. It follows that when the nose of the shuttle and the needle interact as they should, skipping stitches will not be observed. The first thing to do is check that these parts are adjusted correctly.

So, the gap between the needle and the shuttle should not be more than 3 mm. If this parameter is not met, the shuttle will pass far from the needle and will not be able to pick up the thread. It's easier to do this using a magnifying glass yourself.

Along with this, an excessively small distance can lead to needle breakage or blade wear.

Broken needle

Due to improper use or wear, the needle may become dull or change its geometry. The result is an uneven stitch. You can solve the problem by purchasing a new needle.

To avoid skipped stitches when sewing, you need to:

- Assess the condition of the needle. Pay attention to the sharpness of the tip, whether it is deviated to the side, whether there is any external damage on it.

- Make sure that after changing the needle, it goes in all the way and the fixing screw is tightened well.

- Evaluate how the thread behaves as it moves through the mechanism. There should be no hesitation or excessive tension.

Expert opinion

Irina Vasilyeva

Designs clothes, teaches at her own school and advises beginning seamstresses

To ensure trouble-free sewing quality, it is recommended to change needles regularly. If an unusual sound occurs at the moment the tip enters the matter, the needle must be replaced.

Thread mismatch

Another common reason for a sewing machine not to work correctly is a mismatch between the thread and the needle. If you take a very thick thread, the small needle will not be able to cope with its function and will make uneven and irregular stitches.

Therefore, you need to use an elastic thread with a uniform thickness and sufficient strength. Also, the choice should fall on an option without strong torsion. And most importantly, the thread must match the needle number.

Conditions for working with complex fabrics are not met

The reason why a sewing machine skips stitches may not be in the equipment, but in the material that is being processed. For example, if you are working with knitted fabric and a regular needle is selected, extra loops may appear when the fabric is pierced. As a result, a lap loop will not work.

Each time you need to take a needle that is suitable for the type of fabric you have to work with. The choice depends on the type of material, its thickness or elasticity. For example, when processing thick fabric, leather, and delicate materials, you cannot choose a universal needle.

The fact is that different threads and needles are specially designed to make the sewing process easier.

Expert opinion

Irina Vasilyeva

Designs clothes, teaches at her own school and advises beginning seamstresses

If it is not possible to change the needle while working with knitwear, you can try placing thin paper under the fabric to prevent skipping stitches.

Mechanical damage to the needle plate

If the needle plate is heavily worn during active use, the fabric may be “pressed” during sewing. The thread will not be able to pass through it freely and at some point loops will begin to form in the wrong places, which will lead to gaps in the stitching.

This problem definitely requires replacing the needle plate. Otherwise, everything may end in a more serious breakdown.

Incorrect thread tension

If the thread tension is not adjusted correctly at the beginning of work, the stitching will be uneven. The problem is resolved by debugging. This must be done in accordance with the rules specified in the instructions for the specific sewing machine model.

Unsuitable needle

In some situations, the wrong needle is installed on the equipment. This often happens by mistake. Without understanding it, they simply install a needle that does not fit this machine model. So, during operation it will not interact with the shuttle, but will only pierce the material.

Expert opinion

Irina Vasilyeva

Designs clothes, teaches at her own school and advises beginning seamstresses

A sewing machine may skip stitches due to a minor error, but sometimes this indicates a more serious problem. Therefore, before work, you should always check the equipment and monitor its condition.