Elegant work! Processing the neck of a knitted jumper

Knitted fabric is an excellent material that is ideal for sewing warm jumpers, sweaters or cardigans. Craftswomen have long appreciated its ability to hide minor flaws in work, and it takes much less time to sew knitwear than when working with ordinary fabrics. We have previously published patterns of simple and effective knitwear models on the site, and in this lesson we will tell you how elegantly and quickly you can process the neckline on a knitwear product using regular bias tape. You will find the pattern of a jumper with a bat sleeve, the example of which we will use in the master class, in one of the previous lessons.

How to process a neckline on a knitted product

To process the neckline you will need: bias tape with folded edges the length of the neckline of your product + 10 cm, 10 cm of round elastic and 1 button on the stem with a diameter of 1 cm.

Sew the middle seam of the back of the product with a machine stitch, leaving a 10 cm long opening for the fastener unstitched. Overcast the seam allowances and press them.

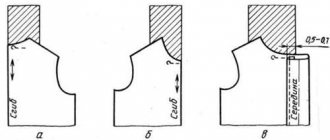

Rice. 1. Bias binding for finishing the neck of a knitted jumper

Trim the seam allowance along the neck of the jumper to 0.7 cm. Fold the seam allowance along one side of the bias tape and pin the bias tape along the edge of the neck allowance. Do not baste the binding so that waves and folds do not form (it may stretch a little during the stitching process). Sew the binding to the neckline, stitching 0.5 cm from the edge.

Rice. 2. Knitted jumper with bias tape

Rice. 3. How to sew binding to the neckline

Fold the tape over the neckline allowance and stitch the tape along the seam. Cut off the free ends of the binding on both sides, leaving 1 cm, fold and pin.

Rice. 4. How to stitch along the edge

Rice. 5. Fold the edges of the binding

Form a loop from the rubber band to the size of the button, wrap the ends of the elastic with several turns of thread, and secure. Pin the loop to the left side of the back at the top of the cut.

Rice. 6. How to baste an elastic loop to a product

Bend the folded edges of the binding on both sides of the cut down and pin it in place. Stitch along the edge of the binding, being careful to stitch exactly along the folded edge of the binding.

Rice. 7. How to fold bias tape onto a product

Rice. 8. How to sew the edge of bias tape to the neckline

Having reached the edge of the cut, turn the product 90° and stitch the binding along the short side, while simultaneously stitching the loop. Fasten the ends of the threads and cut them.

Rice. 9. Cross short stitching

Sew a button onto the right side of the clasp. In Fig. Figure 11 shows a section of the finished fastener from the reverse side.

Rice. 10. How to sew on a button

Rice. 11. Neckline finished with bias tape

You will find even more new interesting ideas on the website of Anastasia Korfiati’s Sewing School. Subscribe to free lessons and sew fashionable clothes with us!

I noticed this type of processing on a branded dress I bought. This processing is very useful for those who want to sew beautiful knitwear , but do not have an overlocker. Very often, on knitted products, the neckline and armholes are processed by facing or turning the overlocked edge, followed by stitching with a double needle. But usually beginner craftswomen don’t have an overlocker. Finishing the edge with a zigzag stretches it, which is not at all beautiful. But I want to sew beautifully, because the reverse side is the dressmaker’s face. This does not mean that you should give up working with knitwear. It is enough to select a material that does not give creases when stretched transversely, then the side and shoulder sections can not be processed at all, but the neckline and armholes can be processed using the proposed method.

Before processing the armhole, it is necessary to sew the shoulder seams. Lay the product on a flat surface and straighten the armhole.

We cut out a strip of knitwear 2 cm wide, not along the lengthwise, but across (at a right angle to the edge) the piece of fabric. This is the direction in which knitwear stretches the most. The length of the strip should be slightly longer than the perimeter of the armhole.

Fold the strip and the product right side inward. Let's baste. We do not stretch the knitted strip; we place it loosely; in the area of curves, you can even press it slightly.

We sew a line at a distance of 5 mm. from the edge. We use, of course, a knitting needle. They usually have a blue bulb. The stitching should not stretch the edge of the fabric. If your machine is stretching the fabric, try loosening the presser foot screw.

Smooth out the seam. Press the allowances onto the binding side.

We sew from the side of the binding, retreating from the stitching seam 1-1.5 mm, i.e. very close to the seam, but without going beyond it.

Cut seam allowances close to the stitching.

We turn the binding inside out and iron it.

Please note that there should be a slight bend (literally 1 mm) of the main fabric to the wrong side.

Fold the free edge and baste. The finished width of the binding should be 7 mm. During stitching, we measure this width throughout the entire armhole.

After this, the armhole should be laid out on an ironing board, maintaining a rounded shape, and steamed well with an iron.

We sew close to the fold, retreating 1-1.2 mm.

After the second armhole has been processed, the product is folded along the axis of symmetry, the shoulder seams are aligned and the armholes are aligned and, if necessary, aligned.

The result is a beautifully finished, clean edge.

Next, align the edges of the armhole and sew down the side seams. I have an overlog, and I stitched with it, but you can sew it on a sewing machine.

We bend the allowances onto the shelf and secure them with a tack.

Finished processing of the armhole of a knitted dress.

The neck is processed in the same way. It’s just more convenient to process it first. First, one shoulder seam is sewn, we process the neckline as described above, and we sew the second shoulder seam. We secure the seam allowances with a tack. Then we process the armholes.

The entire master class on sewing a knitted suit can be viewed here .

Author of the material: Julie 22

Types of necks

The type of technological processing of cuts of knitted clothing depends on the design of the model and the type of fabric. Neck options in knitwear have the same variety as in garments.

The cutout can be:

- round classic;

- round deep;

- V-shaped;

- draped neckline;

- stand collar;

- turn-down collar;

- fantasy options.

Depending on the type of neck and collar, the processing technology changes. In tailored blouses and polos, as a rule, collars are sewn in as in textiles, with preliminary processing of the collar and subsequent stitching. In industrial knitted fabrics, trims and collars are attached using special knitting equipment.

In hand-knitted models, the neckline is tied with a double or single strip of main yarn or decorated with a stand-up collar.

Processing technology

In mass production, to optimize the technological process, special devices and equipment are used to minimize the use of manual work. At home, processing a knitted neckline includes machine and manual operations. The use of a knitting machine needle with a rounded tip, which pushes the fibers apart, and the use of knitted elastic stitching improve the quality of the finished product.

Smooth edgings and eraser trims are used to decorate T-shirts, sweatshirts, basic assortment dresses or sports style models. Stand-up collars with polo-type trims are used to decorate sports dresses and polo T-shirts. Elegant knitted blouses and dresses benefit from hem facings that create a clean edge.

Round neck trim

- Cut out the binding from the main fabric or eraser. Its length when flat is equal to or shorter than the length of the finished neck cut. Make sure that the elasticity and length of the assembled edging are sufficient to be pulled over the head.

- Stitch the piece along the short side to form a ring.

- Fold the piece in half and iron it.

- Fold the binding with the neck cut right sides together, aligning one shoulder cut of the product and the stitching seam of the part.

- Pin together perpendicular to the cut, evenly distributing the lengths of the sections. Sweep if necessary.

- Sew the edge with an elastic stitch or overlock.

- Place or iron a seam stock on the product.

- Place an elastic single or double finishing stitch along the seam reserve.

Kashkorse and ribana

This processing method gives the product a sporty look, which many people like.

The first step is to decide how much material we will need. There is a special formula for this that allows you to find out the length of a circle inscribed in another circle:

- We measure the circumference of the neck according to the pattern

- Divide it by 3.14

- Subtract the width of the finished collar, multiplied by 2

- We multiply all this by 3.14

It turns out perfect! But if you don’t want to count every time, you can use a simpler formula:

Name

- We multiply the length of the neck by 0.7 - we get the length of the collar!

The same formula can be used for the cuffs and waistband.

Processing technology

We cut out the part of the required length (according to the formula) and width (usually 4 cm, but you can put more or less, depending on how you see the finished product), do not forget to leave allowances of about 7 mm

Fold the part in half lengthwise, face to face, cut to cut, and then in width, also in half, and stitch it on an overlocker.

We make an S-shaped seam ironing: iron part of it to the right, and part to the left, with a bend in the middle

Fold the part in the center “face” outwards and iron it - almost done