Types of weaves in fabrics are classified as follows:

- Simple (smooth).

- Finely patterned.

- Complex.

- Large patterned.

Smooth

Before considering the types of weavings, it is worth defining the fibers used in textile production. Fibers are threads made by spinning or chemically spun from natural, artificial or synthetic raw materials.

The warp thread is the fibers stretched over the loom frame. Weft thread is the fibers attached to the shuttle of the loom. During operation, the shuttle moves the weft threads between the warp threads, ensuring overlap.

A repeating weaving pattern is called rapport. Designated by the letter R. Depending on the weft or warp, the indices “y” or “o” are placed, respectively.

The offset shows the number of threads removed from the previous overlap. Designated by the letter S with the corresponding indices “o” or “y”.

The main types of smooth weaves used in textile production are:

- Linen (simple).

- Twill.

- Satin.

- Satin.

Satin and sateen overlaps are combined into one group because they are produced identically and differ in the thread presented on the front side. This group is called satin-satin.

Polotnyanoye

Plain weave is characterized by the arrangement of weft and warp threads in a simple manner, alternating them in a checkerboard pattern. The rapport formula looks like this: RO = RU = 2.

The main characteristics of fabrics produced by this method include properties such as strength and smoothness. Canvases with the same face and back can have different density and stiffness indicators. The surface is smooth to the touch. They produce plain-dyed and patterned fabrics. The drawing is applied by printing.

The following types of fabrics are produced using the simple weave method in the textile industry:

- made of cotton: cambric, voile, madapolam, calico, chintz, calico, etc.;

- from linen fibers: suits, dresses, trim, canvas;

- from silk threads: crepe de chine, crepe georgette, crepe chiffon;

- woolen: cloth.

Thus, hand-woven homespun fabrics are produced. To weave ribbed fabrics, one thread must be thicker. The heterogeneity of the threads creates an even transverse pattern without shifting. Fabrics woven using this method are called false rep fabrics. For example, taffeta or poplin.

Simple weaves give the fabrics strength. The checkerboard pattern of threads demonstrates resistance to tearing and is not prone to abrasion; it can withstand washing in hot water with the use of bleaches and stain removers. Therefore, calico, chintz, and linen are considered leaders in sewing household items and bed linen.

The simple overlap method is considered basic and is used as the basis for complex weaving patterns.

Satin and satin

The ratio of rapport to shift, expressed by the fraction R/S, characterizes two more very popular and sought-after weaves - satin and satin. Unlike canvas floors, the weft and warp threads are intertwined less frequently. This ensures the smoothness and shine of the front surface of the canvas.

On the front side of satin fabrics, weft threads predominate. A typical representative of the group, satin is woven from double-weave threads produced using fiber twisting technology, which makes the fabric strong and wear-resistant.

Satin weave is a variant of satin, made identically, but with a predominance of warp threads on the front side. With this method, the weft threads are brought to the front side through 4 - 5 or more warp threads. The technology makes it possible to obtain smooth fabrics with a characteristic satin shine. The fabric is slippery, light but durable. During the sewing process, the sections are prone to fraying.

Satin-satin weave is used in the production of the following materials: satin, flannel, eraser, satin, some types of drape, suit and dress fabrics, crepe-satin, lining and corset materials.

Twill

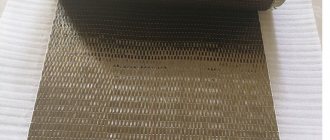

Fabrics with a diagonal rib with an angle of inclination depending on the shear are produced using the twill overlap method. The angle is 45 degrees. During the weaving process, an asymmetric shift of 1, 2 or 3 threads is performed.

The traditional method is used to produce twill fabrics in which the hem is directed from top to bottom, from left to right. There are also canvases in the opposite direction. This method is a reverse twill weave.

Fabrics obtained by twill weaving demonstrate the following properties: density, unlike other main weaves - greater thickness and weight, the ability to stretch, especially diagonally, and softly drape. Smooth, abrasion-resistant, they are inferior to other types in terms of strength. But this is not critical.

Examples of material: twill, wool/silk blends, lining.

Reinforced twill has wide oblique stripes, thanks to this pattern the wear resistance of the material increases. This is how tartan, Boston, Cheviot, Bumazea, gabardine, etc. are produced.

There are subtypes of fabrics with twill weave. They make up a range of woven materials.

Broken

Broken twill represents a herringbone pattern. This type is characterized by the use of reverse twill weaving. Examples of fabrics: chevron, various types of dress and suit materials.

With shift

A subtype of the twill type with a shift is a modified version of the broken one. It is performed in a similar way to it, but with a shift in rapport along the warp or weft. Used to produce a material called gribson. This type of weaving is called reverse-shifted. Performed on the basis of twill with a rapport to shear ratio of ¼; 2/2; 2/3.

Diamond-shaped

Diamond-shaped fabrics are produced on the basis of twill weaves with a shear ratio of ¼; 2/2. They are also called cross-shaped or lozange. The texture of the fabric is formed by a pattern of rhombuses of different sizes. Examples: decorative and dress.

Complex

Composite or quilted twill is a highly resilient, high-strength fabric characterized by the presence of raised stripes of varying widths. It is made on the basis of rapport ½, 2/2. Examples of materials: decorative, dress.

Other types of twill include zigzag (with a variable inclination of the warp and weft threads), shadow (with a shadow transition), curved (changing the angle of the hem). Examples of fabrics: decorative and dress.

Review of matters

The yarn used for twill weaving has the same effect on the properties of the finished fabric. The versatility of the fabric lies in the use of various fibers (artificial and synthetic). Denim fabric is often made from it, it can be:

- One of the cheapest and thinnest materials is Gin, produced from untwisted yarns of low density;

- Jeans. High-quality and dense material, the weft threads are twisted. Recently, elastane has often been added to denim to make it more elastic;

- Stretch. There are also warm denim, with thermal material on the inside as a lining;

- Denim with a ripe herringbone pattern is called Broken Twill. The first jeans were made from it;

- One of the most expensive and best fabrics will be Denim and Selvage. Jackets, coats, and suits are made from them.

To visually understand what is being said, you need to watch several master classes on weaving.

Material Denim

Wool twill

Basically these are quite dense and warm fabrics. Twill wool is used to create winter clothing.

What does gabardine look like?

What fabrics are made from wool twill

- Gabardine is a material made from merino sheep wool. Fur coats, coats, and sweaters are made from it. Used as furniture upholstery. She looks quite elegant. The peculiarity of this fabric is that the scar on the outer side is tilted at 60 degrees and the back is shiny;

- Tweed - hats, suits and coats are made from this fabric. Made from sheep's wool. Properties of the fabric: keeps warm, does not wrinkle, has a beautiful appearance.

You might be interested in what double-thread means: description and use of Turkish fabric

Mostly suits, outerwear, hats or demi-season items are made from woolen fabric.

Wool blend

For twill weaving, mixtures of threads are used. Wool blend fabrics are very popular. Cotton yarn is used as the warp, woolen threads will be used as weft. They are most often used to make coats and special clothing for workers. It is quite difficult to care for, so you need to follow the rules written on the label.

Natural silk twill

Cotton

Pure cotton fabrics are very dense. Such material is called harsh.

One of the most beautiful and popular fabrics to use will be denim fabrics with a pattern, they are called jeans. For the base in the canvas, dyed yarn is taken.

Silk and semi-silk

Silk twill fabrics are used to make sets of linen that are soft and pleasant to the touch. For semi-silk fabrics, silk fabric and cotton weft are used.

Viscose

Viscose thread is made from cellulose. Thin viscose twill fabrics are widely used as linings in hats or outerwear. Many women's wardrobe items are made from the material. For example, autumn dresses or office suits.

Lining material

Structural

Structural types include derivatives of the main ones using threads of different thicknesses. To create a relief or pattern, the warp or weft doubles in thickness by 2–3 times. Despite the structure of the fabric, it is soft and durable. Depending on the origin of the fibers used, stiffness values may vary.

Reps

Rep refers to materials derived from simple (plain) weave. The material is divided into three groups: main and weft reps, half reps. This division depends on which thread creates the thickening.

A transverse scar forms on the surface of the rep; on fabric produced by weft rep weaving - longitudinal.

Half-reps can be either weft or main. In prolureps technology, repeats with floorings of various sizes are used.

Using this method, fadeshine, flannel from cotton raw materials, dress and suit types of wool, silk and cotton rep are produced.

Gozhka

Another representative of the simple weave subtype is matting. The threads are overlapped by reinforcing the weft and warp in repeat. The surface of the canvases has a structure in the form of large squares alternating in a checkerboard pattern. Oxford and two-thread are typical representatives of matting.

Twill

Twill is a fabric produced using a twill weave, where the warp and weft threads exhibit a 2/2 ratio. The peculiarity of the material is that twisted threads are used during the production process. The history of its origin is connected with Scotland, where its production was driven by the desire to create warm clothing that would protect against cold winds.

The material dyes well and retains its color brightness. Its name was mistakenly confused with tweed during the time of the Duke of Windsor. And the characteristics of these two fabrics are similar. If initially twill was made from cotton fibers, today mixed versions are more common.

Made from cotton (twill-satin), mixed with polyester, with elastane (twill-stretch). The canvases have a textured surface and a noble shine.

Finely patterned patterns

Finely patterned patterns include 2 subtypes:

This is a modified plain weave. They are easy to distinguish by the characteristic scar that forms on the surface. Exists in 2 types:

Rep has a rather rare grouping of threads, which is why the fabric is very soft. But at the same time it has less strength and elasticity. When cutting them, it is important to observe the location of the direction of the scars. If it does not match, the canvas is likely to become deformed and unusable.

Gozhka

The weave of threads in a matting is very similar to that of linen, but also has some differences. The thread pattern is much more pronounced. The fabric is very dense, but at the same time soft and pleasant. It has high elasticity and is not afraid of tearing.

The weft thread and the warp thread are symmetrical to each other and form a certain square. The report can have a 2x2 proportion or an enlarged 4x4, as in the presentation.

Derived twill variants

Twill weaving has the most derivatives. Each of them differs from the original type by lengthening the floors. Therefore, the diagonals become extended and more pronounced. They can be one-sided or equal between the wefts and the warp.

Depending on this proportion, the following varieties are formed:

Derived variants of satin and satin types

Derivatives of these types include modified and reinforced fabrics. For example, in reinforced satin with 8 threads of each weft row there are also 2 warps and 6 wefts. As a result, the fabric is much stronger.

Crepe

The technology for the production of crepe fabrics is based on the use of combined weaves. The surface of the material has a fine-grained texture. Overlapping threads are made on a linen basis in various combinations. Thus, additional overlaps are made on the surface of the weaving fabric, scattered in a certain order.

Crepe floors can be single or group. There are options using different technologies. Examples of fabrics: crepe satin, crepe chiffon, crepe de Chine, etc.

In addition to durability and attractive appearance, crepe fabrics are easy to sew. The edge of the cut does not crumble. The products retain their shape well, do not stretch or deform.

Diagonal

Diagonal is a fabric made using twill weave. There is a small, even scar on the face, located diagonally at an angle of 45 degrees.

The properties of dense matter include: resistance to tearing and abrasion, the ability to retain shape in the product, practicality. The fabric stretches diagonally, does not shrink when washed, and is durable.

Waffle

Waffle fabric is a textured textile material used in the manufacture of home textiles, with a characteristic relief pattern in the form of recessed cells with sides. Weave based on diamond-shaped twill with ¼ repeat.

Absorbs moisture perfectly, does not leave lint on the surface being wiped, and has a massage effect. They are made from cotton, less often from linen fibers.

Jacquard types

Jacquard fabrics are distinguished by the fact that the design on them is not produced by printing, but is performed at the stage of weaving the threads. Threads dyed in different colors are used in weaving. As a result, canvases with double-sided patterns are obtained.

Jacquard can be large or small patterned. Depending on the author’s intention, up to 45 threads of different shades can be involved in the overlap. Jacquard fabrics are divided into simple and multi-layer. Large jacquard weave and warp knitwear are made on the basis of this weave.

Textile fabrics with jacquard weave are light and durable, do not stretch, retain their shape, are not subject to fading or shedding, and look very expensive and presentable. The cost of this material is high. But a jacquard product will also last for more than one year. With proper care, such things do not lose their original attractiveness for decades.

Finely patterned combined schemes

Combined patterns include composite types of weaves in which they alternate. In this case, alternation occurs and an unusual pattern is achieved.

Types with longitudinal or transverse stripes

Relatively modern types of weaving. They are interesting because it is possible to combine any simple species without losing their identity. On the finished canvas they fold into interesting shapes. It is possible to achieve a diamond-shaped pattern, cross-shaped, square, etc.

The following types often alternate:

Combinations are chosen randomly, depending on the specific pattern desired. It is important to follow the rule of pattern difference. The scars should go in different directions, not overlap and intertwine into one new one.

Crepe schemes

They are simple schemes, but with arbitrary extension of the floors. In some cases, they are created by combining two different types of weaving. The resulting pattern will be similar to silks formed using crepe twisting.

Due to its properties, crepe turns out to be very capricious. It shrinks easily even under normal conditions, but at high temperatures and humidity it deteriorates sharply.