Why are cushioning materials needed?

In the manufacture of clothing, a huge role is played by interlining materials, which are placed between the main fabric and the lining, hence the name - interlining. There are three main functions of the gasket:

- Giving and maintaining the shape of individual clothing parts. Not a single classic jacket or coat is complete without duplicating materials. They are used to glue shelves, edges, lapels, cuffs, collars, belts, pocket flaps, leaves. Shoulder pads and sill pads are also used to give shape.

- Increases wear resistance and protects parts from stretching. Some areas of the product experience heavy loads, such as fasteners, pockets, vents, and necklines. Therefore, these places must be duplicated - the zipper allowance, trims on shirts and blouses, neck cuts, facings, pocket entrances.

- Protection from wind and low temperatures. If you decide to sew a winter coat or jacket, in this case you will need insulating materials: batting, padding polyester, down, wool, which are used to duplicate or stuff the product.

Types of cushioning materials

There is a large amount of duplicate material. Sometimes several types of pads can be used in one product; this applies to men's jackets, cardigans and coats. Spacer sheets can be adhesive or non-adhesive . Adhesive ones are made by applying special glue on one or both sides. Depending on the method of application, the adhesive layer is of two types: dotted and continuous.

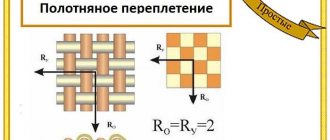

There are also three types of base on which glue is applied: woven , non-woven and knitted . The fabric base has a grain thread, which must be taken into account when cutting parts. These types of pads are also called thermal fabric. The non-woven base is a pressed mixture of fibers that does not have a specific direction. Knitted backing fabrics are used for sizing knitwear products to maintain the elasticity of the materials and at the same time give them shape.

Let's look at the most common types of duplicating materials separately.

Description of doublerin

Dublerin is made from a cotton base with the addition of polyester and viscose fibers. The ratio may vary.

What does a doubler look like?

To make the adhesive layer, the following compounds are used: ethylene vinyl acetate, polyethylene or polyamide. These substances melt at different temperatures.

It can also be of different densities and widths. Dublerin colors are usually neutral, black or white. But sometimes they are colored, matching the color of the product.

So that it can be glued to the base, glue is applied to it in a spot.

How to care for products using dublerin

This material is quite easy to care for. You just need to follow the washing rules indicated on the product.

The process of gluing the lining

If the lining has been glued correctly, then the products can be washed at high temperatures. It is advisable to squeeze only in delicate mode. If the dublerin has come off, it can be carefully glued using a hot iron.

What can you replace dublerin with if you don’t have it on hand? Cardboard or organza will cope with its role quite well.

You might be interested in Features of the properties of taslan fabric and its use

Positive qualities of doublerin

Pros of the fabric:

- Does not wrinkle;

- Allowed to drape;

- The base of the material does not stretch;

- Retains its shape for a long time;

- A large number of varieties.

Disadvantages of the material

To get started, you need to choose the type of dublerin; it must match the fabric. When using fabric dublerin, you need to pay attention to the elasticity; it must match the product.

Prices for lining materials for 2021

Note! The only drawback is its cost. The price for 1 meter of fabric dublerin is about 100 rubles.*

This material is of quite high quality because it uses natural threads.

What clothing details are duplicated?

- For outerwear, you can duplicate: shelves, neckline, top collar, cuffs. This is done to give shape to the product;

- Partial duplication: pockets and side details of things. Used to impart rigidity and prevent stretching;

- Duplication of stretch cuts: hem of clothing, bottom of sleeves, armhole cuts, collar. Used mainly in coats or jackets, very rarely in dresses;

- Duplication is done before grinding the products;

- The direction of the grain threads of the main material and the linings must match;

- Basically, linings are made without allowances, exactly according to the pattern mark.

Material colors

How to work with it

In order not to spoil the product, when gluing dublerin, you need to follow some instructions. It is necessary to choose the type of fabric that will suit the finished garment. Professional seamstresses recommend decatifying the dublerin before use. This is easy to do: the lining needs to be immersed in water for several hours, and then taken out and dried. Spinning cannot be done. This process must be done to ensure that the product does not shrink after the first wash. When creating, natural fibers are used, so there is such a risk.

Spot adhesive base

After drying, the fabric is ready for use:

- Cut out the parts needed for the product from the lining;

- Spread the item you want to work with on a flat surface;

- Place a piece of dublerin on top of it with the adhesive side down;

- Place an auxiliary cloth or bandage on top, which is used for ironing;

- Using a hot iron, iron the product;

- It must be stroked evenly, with light movements, but not fidgeting with it in all directions;

- The product can be handled only after it has cooled completely.

You may be interested in: What are the types of waterproof fabrics for awnings?

Crinoline

The collar has a fabric base. The composition can be natural (cotton, linen, wool, horse and camel hair), artificial and mixed. This is a dense fabric that is used primarily in the manufacture of men's jackets and coats. There is also a distinction between adhesive and non-adhesive fabric. The adhesive-coated edging is glued to the main parts using an iron; non-adhesive edging is quilted by hand. The traditional technique for making elite men's jackets involves up to five layers of edging, which is sewn with a fine stitch by hand. In mass production and budget studios, side fabric with an adhesive coating is used.

Doublerin

Dublerin is an adhesive cushioning material that can be woven or knitted. In an oblique direction it tends to stretch, so when cutting a woven fabric, the direction of the warp thread plays an important role. Dublerin varies in density: there is thin, which is used for sewing products from thin materials (chiffon, silk), medium (suit fabrics), dense (coat fabrics), there is also shirting - an ultra-dense material, similar to thin cardboard, which is used for duplicating collars and trims in shirts.

Brands and cost

The main manufacturers of adhesive products are the following brands:

- Hansel, Kufner, Fulda - Germany;

- Baldin, Koenig - Belgium;

- LanourPicardie - France;

- Wilen - UK.

In Russia, materials are produced by , located in the Moscow region, and TIM-holding in Krasnoyarsk.

Important! The company, known as the first developer of non-woven fabric, also produces adhesive padding polyester.

The latest technologies make materials of higher quality, namely:

- increase the strength of joints;

- increase shape stability;

- ensure compliance with environmental cleanliness requirements;

- save thermal energy by lowering the temperature and time of the gluing process of materials.

Japanese products are sold on the Russian market. This company has been a leader in Japan in the production of adhesive materials since 2009. The company entered the European market, gradually gaining momentum.

The company achieved trust and status thanks to a combination of unsurpassed quality and flexible prices. The company strictly controls the production of materials at every stage. The manufacturer offers customers a wide range of products.

You might be interested in what nylon is: description of fabric properties, naturalness and elasticity

High-tech equipment used to create fabric has allowed products to regularly enter the European market. They are purchased at an affordable price in any quantity. The products have received certificates in Russia. They have been tested and found to fully comply with the standards and technical requirements.

Danelli adhesive products offer patented materials. They allow you to duplicate fabrics even at 5 degrees. The parts will remain resistant to washing and chemical treatment.

Manufacturer logo

The company produces all types of materials necessary for sewing outerwear, blouses, and trousers. The popularity of this brand is due to the technology of applying glue to the surface. It is distributed by computer and a clear distance between points is maintained. High quality gluing with any coating is guaranteed.

Average cost of materials:

- a product for appliques measuring 100×50 cm costs 170 rubles*;

- dublerin for a collar 260 g/m2 with a width of 112 cm will cost 360 rubles;

- a spider web on paper 112 cm costs 340 rubles;

- cobweb in a roll version, 83 cm long, 112 cm wide - about 5,000 rubles;

- non-woven fabric 75 grams per square meter, width 100 cm - 80 rubles.

Nonwoven

The name non-woven comes from the Vlieseline brand of the same name and has become a household name. This is a non-woven paper-like material based on sized and unglued cellulose fibers with the addition of polyester. Non-woven fabric has a number of disadvantages compared to dublerin. Thin material breaks easily, and when used, the item quickly loses its shape. Thick, cardboard-like, it gives strong creases at the folds. However, there is a type of non-woven fabric - thread-stitched, which is quilted by machine. Its properties are more durable.

How to choose duplicate materials?

- It is advisable to purchase a fabric-backed gasket, as it gives the greatest strength to your product. And you will be sure that the item will not lose its shape during the first wash.

- If you need to strengthen the cut of the neckline or armhole, and there is no adhesive edge at hand, then you can use a strip of dublerin cut on the bias.

- When choosing dublerin, you need to pay attention to the density, which should correlate with the density of the main fabric.

- For light chiffon and silk products, you need to take a thin pad, for coat products, respectively, a thicker one.

- Also, cushioning sheets vary in color, usually white and black, but you can also find colored ones. Therefore, fabrics of light shades are sized with white dublinin, dark ones with black.

- And one more piece of advice. Before gluing the part, try it on a piece of the main fabric, then you will understand what density you will get in the end.

- Also make sure that the adhesive layer is located towards the back of the product, and not towards the iron!

- When working with an iron, use an ironing iron, placing the part to be glued between it. This will protect the iron and ironing board from traces of glue.

Types and properties

The main properties and advantages of all types of adhesive fabrics over non-woven cushioning materials are:

- good ability to drape;

- strength. Do not tear;

- durability. They last much longer than non-woven fabrics;

- flexibility. They do not form rigid bends when the product is turned inside out.

And yet they all differ from each other in density and degree of elasticity and are divided into two large groups: elastic and inelastic.

Inelastic

They can be hard and soft. The base is made of polyester or cotton, they do not stretch and are used to give the fabrics additional strength and dimensional stability. We advise you to read: what kind of fabric is polyester.

- It can be chiffon for completely transparent clothes.

- For the manufacture of corsets, calico is used, which gives the product additional rigidity and does not allow it to unravel at the seams.

- There is also a special thermal fabric for fur and leather products.

- Collar thermal fabric has a continuous adhesive coating and is much more difficult to bend.

Elastic

They can be made from thin lint-free knitwear for duplicating thin fabrics, from knitwear with lint for soft products and thick clothes (thanks to the lint, the adhesive base remains completely invisible).

When choosing adhesive fabric, you must follow an important rule: it can be stiffer than the main one, but it should not be denser.

The disadvantage of woven-based gaskets is their higher price (when compared with non-woven or spunbond).

What is adhesive tape

There are several types of fabric sizing tapes:

- thread-stitched on a basis of calico or thread-stitched non-woven fabric. Used to strengthen rounded cut details, such as armholes or necklines.

- thread-stitched on the bias, reinforced with soutache or stitching. They are more durable, so they are great for decorating edgings or cuts. As a result, processed edges and seams are virtually invisible.

- adhesive web for fabric: this is the thinnest, lightest sticky transparent material, which is usually used for processing the bottom of clothes. It is also used to secure stripes on the front side of the product or for minor repairs. However, it is not suitable for every fabric.

Watch the video on how to use adhesive fabric for a patch:

- mesh: this is a strip of paper on which glue of a certain width is applied where the glue is applied in the manner of a mesh. The tape is used in a similar way to cobwebs, but paper provides certain advantages: it can be easily removed after heat treatment.