Weaving weaves

WEAVINGS

If you pick up a magnifying glass and carefully examine the fabric, you can see how the threads are intertwined. In some fabrics (gauze) this can be seen without a magnifying glass. Yarn is used to make threads. It is obtained from fibers. Even in ancient times, people knew how to connect individual thin, short fibers into long threads. At first it was the fibers of wild plants - hemp and nettles, then - animal wool, and then - the fibers of cultivated plants - flax and cotton.

Fiber

- a thin unspun thread. It comes in different lengths, shapes and thicknesses. The fibers from which yarn, threads, and fabrics are made are called textile.

For many hundreds of years, people made yarn by hand: they pulled a thin ribbon from a mass of fibers with their fingers and twisted it. Then they began to produce yarn using hand spindles.

The process of making fabric from yarn is called weaving. Fabric is made on looms operated by weavers. The fabric is obtained by weaving threads.

BASE FABRIC

- a longitudinal system of threads in fabric. In the process of weaving it on a loom with threads of another weft system, a textile fabric is formed.

Weaving not only gives fabrics a different appearance, but also changes their properties. So, the more often the threads are intertwined, moving from the front side to the back side and back, the more they are connected to each other, the more stressed, the structure of the fabric is stiffer, and the strength is greater. Threads with frequent bends give the surface of the fabric a matte appearance, while long overlaps passing over several threads make it smooth and shiny. Fabrics whose surface is formed by long overlaps are more resistant to abrasion, but threads that are weaker in the overall structure of the fabric fray more easily along its cut.

Fabric structure

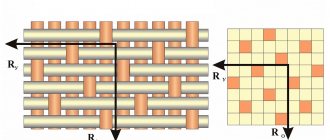

The fabric is a spatial mesh of rectangular or square cells formed by two mutually perpendicular systems of threads - warp threads located along the fabric and weft threads lying across the fabric. The different sequences of weaving the warp and weft threads in fabrics create various patterns - the warp and weft threads go around one another or overlap several threads at once, located either on the front or on the wrong side of the fabric.

Fabric finishing

The fabric that is removed from the looms is called harsh or harsh.

It has a rough surface. The color of the fabric corresponds to the color of the fibers from which it is made (linen - grayish, cotton - yellowish).

Fabric finishing

Raw fabric is subjected to finishing in order to improve the quality and properties, giving the fabric a marketable appearance.

Stages:

- pre-finishing (cleaning and preparing fabric);

- whitening;

- coloring;

- drawing;

- final finishing.

Fabric that has been finished is called finished. Depending on the finishing method, various types of fabrics are obtained

- Rapport is a repeating part of a pattern on fabric.

- There is rapport by warp - Ro and rapport by weft - Ry

- Shift is a number indicating how many threads are removed from the overlap of the next thread from the previous one.

Weave weave

Weaving is the interweaving of warp and weft threads. There are different types of weaves. The appearance of the fabric and its properties depend on the type of weave. The simplest and most common weaving technique is plain weave. In it, the threads intersect through one another: the weft thread passes alternately above and below the warp thread. This way, the weaving pattern is the same on both sides of the fabric.

Weave fabrics

All weavings are divided into four classes:

- simple (smooth) weaves, giving the fabric a smooth, uniform surface;

- finely patterned weaves with patterns of small figures formed by modification, complication and combination of smooth weave;

- complex weaves formed from several systems of warp and weft threads;

- large-patterned weaves that form a variety of large patterns on the fabric;

In simple large-patterned weaves, patterns are created by one warp and one weft, in complex ones - not by systems of warp and weft threads.

TYPES OF SIMPLE WEAVES

PLAIN WEAVE

PLAIN WEAVE

- weaving, in which there is a strict alternation of warp and weft threads in a 1:1 ratio. Moreover, if the first warp thread has reached the surface, then the second is covered with a weft thread, etc. This strict alternation occurs along the entire length and width of the fabric. This produces material that is the same on both sides.

TWILL OR DIAGONAL WEAVE

TWILL OR DIAGONAL WEAVE

- one in which each weft thread in relation to the warp thread in each next row is shifted one move to the right or left. The intersections of the threads form diagonal stripes on the surface of the fabric at an angle of 45 degrees. If the wefts are moved to the right, you get a knit twill, if you move to the left, you get a purl twill.

SATIN WEAVE

SATIN WEAVE

- a weave in which at least five warp threads cover the weft, which comes to the surface above only one warp thread.

Such an atlas is called the main one. If at least five weft threads cover the warp in such a way that only one warp thread appears on the surface of the fabric, it is a weft satin.

Properties of fabrics

Signs of identifying the front and back sides of fabric

The finished fabric has two sides - front and back, the same width along the entire length of the fabric.

To the next lesson:

- "Iris" threads, 2 colors

- thick cardboard

- Ruler, pencil, scissors

Twill is another type of weave

With twill weave, the weft thread overlaps the warp threads not through one, but through three, goes under the fourth thread, overlapping the next three. Each of the further rows is shifted by one vertical thread. A special feature of fabrics made with twill weave is a pronounced diagonal relief on the front side. The slope of the diagonals depends on the combination of weft and warp thread densities.

Twill weave is used to produce cotton, linen, wool blend and wool fabrics - twill, tartan, teak, tweed, Boston. All of them are distinguished by greater softness and plasticity compared to fabrics made with plain weave.

Complex Twill

There are many varieties of twill weave. Among them: reinforced twill, multi-strip, broken, shadow twill, diamond twill, reverse, shifted, curved.

Shadow twill

Curved twill

Varieties

raznovidnosti-1

raznovidnosti-2

Satin fabric can be smooth or patterned. Smooth types include:

- crepe-satin. Soft, reversible fabric. In production, smooth warp threads and twisted weft threads are used;

- Duchess. Very dense and hard material with a shimmering shine. Used for sewing wedding dresses;

- shoe satin. Used to make elegant women's shoes.

For many materials, smooth satin serves as a background. It is complemented by a pattern of various application methods:

raznovidnosti-3

raznovidnosti-4

- jacquard - the design is obtained using colored threads or other weaving methods;

- printing - the design is applied with printing rollers;

- embossing - the pattern is extruded with a thermal roller;

- embroidery - the design is embroidered on ready-made satin fabric.

Based on the types of patterns, the following types of atlases are distinguished:

- Khan-atlas, Margilan silk or Khan silk are made from natural silk threads of different colors. The results are smooth flickering transitions. This material is used for sewing national costumes in eastern countries. One of the names comes from a city in Uzbekistan - Margilan - one of the ancient centers of silk production.

- Pompadour - with golden or silver embroidery, usually in dark shades, reminiscent of brocade. Named after the favorite of Louis XV.

- Maintenon - with flowers embroidered on a dark or light background, named after the favorite of Louis XIV.

- Trianon is a satin with contrasting floral patterns in the form of large leaves, clusters, and bouquets. Named after the palaces located on the territory of the French village of Trianon.

Read about: environmentally friendly fibers: description of types and properties.

Satins can also be divided into types:

- silk-satin is a dense material, the peculiarity of which is the presence of two sides: the back is cotton, and the front is silk;

- Mako-satin is 100% cotton fabric without the addition of other fibers. It is made from thin threads with a mandatory ratio of transverse and longitudinal threads - 31 to 50;

- Jacquard-satin is a fabric with a pattern on the front and back sides. The pattern is obtained precisely thanks to weaving. A variety is stripe satin with a pattern in the form of stripes;

- coupon satin is a material with a printed pattern of a certain size for a specific product. For example, bed linen: duvet covers and pillowcases have complete compositions, rather than just a repeating pattern.

Basic properties

The strength of such material is ensured by the density of the weave and the thickness of the fibers: to visualize this more clearly, visually compare gauze and a calico duvet cover. At the same time, linen fabrics are lighter, thinner and more resistant to aggressive washing than more complex weaving methods. Thus, gentle care is recommended for satin so as not to damage long strands of threads. Due to its double weaving, jacquard is dense and thick.

The main properties of fabrics of this weave:

- resistance to mechanical stress;

- dullness;

- smoothness;

- the front and back sides are the same;

- rigidity (at high fiber density).

Types of fabrics and their properties

The composition of the threads affects the final properties of the material as much as the method of weaving them. Almost all types of fiber are used for plain weave.

The most common is plain weave cotton fabric.

Examples:

- Calico is a lightweight material with excellent hygienic properties. It wrinkles little, withstands many washes, retains color and strength.

- Chintz is the second most durable cotton material after calico. It’s just as light, pleasant to the body, and colors well. The advantage of chintz is its low cost and hypoallergenicity.

- Batiste is a translucent fabric made from twisted cotton threads.

Silk fabrics with plain weave are no less common than cotton ones:

- Crepe de Chine is an elegant fabric with threads of raw silk at the base, features - roughness, density, light shine.

- Chiffon is a transparent and lightweight fabric.

- Crepe georgette is a dense translucent material made from twisted threads. Drapes well.

Linen is a very strong raw material; when woven in plain weave, it forms fabrics of high strength:

- Canvas is a coarse material made from thick yarn, very durable, usually treated with water-repellent agents.

- The lining is a very tough, wrinkle-resistant fabric.

What plain weave fabrics can be made from wool?:

- Cloth is a very dense material: wool fibers intertwine and cover all the spaces between the threads. Externally, the cloth resembles felt. Very soft and strong fabric.

- Flannel is a wool, cotton or mixed material with light double-sided pile. Very soft, retains heat well.

Where are they used?

The main areas of application of fabrics of this type are:

- men's, women's and children's casual clothing;

- bed and underwear;

- home textiles;

- elegant outfits;

- work and protective clothing;

- bags, mittens and other auxiliary products;

- furniture upholstery, etc.