In the northern countries, great importance is placed on technologies that make it possible to produce warm winter clothes. How warm the clothes will be depends on what kind of insulation was used during the manufacturing process. Finland became the country where the technology for producing synthetic material was discovered. In Russia it is called thermofin.

Manufacturing technology

Thermofin insulation, reviews of which you can read in the article, is manufactured using high-tech machines, and production is fully automated. Processes are controlled by computers. The raw materials are biocomponent and conventional fibers. The first of them have a polyester core and a low-melting shell. Both fibers enter the conveyor in the required proportion. This mixture is combed, which allows you to obtain an absolutely even structure. At the next stage of production, melting occurs, where special furnaces are used. Under the influence of high temperatures, the shell of the biocomponent fiber is initially twisted and then fixed to conventional fibers. This allows for a three-dimensional design. This process can be called very important, and the quality of the insulation material will depend on how correctly the temperature is selected, as well as the time calculated.

What is important to know about the material

If you choose the parameters incorrectly, the material may turn out to be too hard or unacceptably loose. In order to obtain thermofin insulation, reviews of which will be useful to read before purchasing clothes using this material, the finished fabric passes through cutting shafts. At this stage, the material acquires a smooth edge and becomes uniform in width. The parts are cut out using a laser meter. After this, the product can be considered ready. Before being sent to the customer, the material goes through a vacuumization stage. This maintains the necessary softness and structure of the layer.

Feedback on characteristics

If you are considering thermofin insulation, you are advised to read reviews about it. Consumers mention softness, which is explained by the absence of a calendering step in the production chain. The insulation is not subject to rolling with hot rolls to expand and compact the material. Users of clothing that contains this insulation note that the material has low thermal conductivity. This quality is the result of the painstaking work of technologists who created the fabric for the harsh Russian winters. The higher the density of the insulation, the warmer the products will be.

In what areas is it used?

Nowadays thermofin insulation is used when sewing a wide variety of types of clothing . These are city jackets and coats for the off-season and winter, children's jackets and overalls, envelopes for newborns, and sports models. A variety of hats are produced using this insulation. It is popular as a filling for pillows and blankets and a warm layer in sleeping bags.

Manufacturers of workwear and uniforms are the leaders in orders for thermofin for their production . After all, it creates the necessary comfort during operation in a variety of conditions, even extreme ones.

Suits, jackets and overalls for drillers and installers, dockers and logistics handlers, uniforms for guards and security guards - representatives of many professions will appreciate the benefits of products with thermofin.

In workwear for harsh male professions, they also take into account not only a large gradation of weather indicators, but also the physical activity of workers, as well as the duration of their stay in the open air at low temperatures.

Reviews about durability and environmental friendliness

It should also be noted that it dries quite quickly, which is due to the lack of the ability to absorb moisture. Modern consumers also choose this insulation for the reason that it is environmentally friendly. Various impurities are not used in the production process; the technology involves the use of granules of primary raw materials. Termofin has the Eco-Tex Standard 100 certificate, which confirms the international quality standard. Today, thermofin (clothing insulation), reviews of which are almost always only positive, is used very often, during operation it does not accumulate unpleasant odors, among other things, it can be used by people who suffer from allergies. The material is hypoallergenic. You can count on wear resistance and a long service life. If a product containing the described insulation is used carefully, then you can count on durability and preservation of its original shape, as well as appearance. In addition to all the above advantages, we can also highlight the affordable cost; this insulation has no equal in the price segment.

Thermostek Caviti and Thermostek Light

Caviti thermostack is a rigid slab made of mineral wool. It is used for insulating walls, roofs, attics, attics, ceilings, planes with any angle of inclination in buildings and structures for various purposes. The advantage of the Thermostek Caviti material is its long service life when used correctly, it is not susceptible to rodents and insects, and has the necessary fire safety and sound insulation characteristics. However, during installation it should be taken into account that it is not moisture resistant, that is, it requires steam and water protection. This insulation from the manufacturer is an economical option for a thermal insulation solution.

Thermostek Light differs from the above material in density. It is also used for insulating various types of structures in such a way that the material itself does not bear any additional load. Thermostek Light is slabs 50-200mm thick, 1000mm high, 600mm wide, with high-quality insulation from the manufacturer. During installation, it is recommended to lay it tightly in structures (joists, sheathing, etc.) and cover it from the inside with a vapor barrier, and from the outside with a waterproof barrier. Like Kawiti, it is fireproof, environmentally and human friendly, non-toxic, rodent resistant, easy to use and affordable.

Feedback from experts on the scope of application

If you are interested in thermofin, it is recommended to read the reviews in advance. If we are talking about the area of application, then we cannot fail to mention that this material is quite widely used in the manufacture of special-purpose and sportswear. These materials are used to sew sleeping bags, uniforms, and hats. As experts emphasize, material with a density of 150 grams per square meter is used for sewing demi-season clothing; with an increase in density ranging from 250 to 430 grams per square meter, the material is used for making winter clothing. Termofin quite often becomes part of the filling for pillows and blankets. Due to the fact that the insulation is absolutely environmentally friendly, it is successfully used for the manufacture of warm products that are intended for newborns and children.

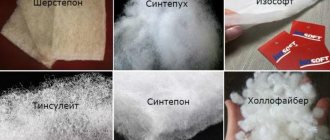

Insulation for clothes. A small digest of the main brands of synthetic filler

As in the well-known expression “prepare your sleigh for winter in summer,” we suggest preparing for sewing a winter collection in advance and familiarizing yourself with the main range of synthetic insulation. In modern urban clothing, it's time to move away from bulky warming fillers. Shoes and outerwear should provide warmth while being elegant and light. So:

Insulation Sintepon

Good old synthetic winterizer is a long-proven inexpensive synthetic filler. It is used in the production of winter clothing, blankets and furniture.

This material has thermal insulation properties that allow items filled with it to be used at temperatures down to approximately -20 degrees. At the same time, it is lightweight. Sintepon makes warm and at the same time almost weightless soft blankets.

If moisture gets in, the material dries quickly, it is moisture resistant and does not absorb odors.

The elastic properties of this filler allow products to retain their shape well and not deform with frequent use and washing. At the same time, its volume makes things soft.

A good padding polyester is environmentally friendly. Bedding products made from this filler are safer even than products made from natural materials. Bacteria and bed insects do not develop in it. In addition, this material is durable and does not produce dust.

Holofan insulation

Holofan is a modern technological insulation, an improved padding polyester. Most often it is used in the production of winter clothing for children.

Hollophan fibers are hollow (this explains its name from the English word hollow) and its properties are close to natural fluff. Therefore, down jackets made from this filler are very warm and light in weight. This filler can withstand even deep sub-zero temperatures. At the same time, it is comfortable even in positive temperatures.

The structure of twisted fibers is springy, so the material easily restores its original shape and retains its volume even after long-term, repeated use. This material is much stronger than most other synthetic insulation for outerwear.

The advantage of holofan over down products is that they can be washed in a machine and are easy to care for. The washing mode in any type of machine is 40%. The material does not shrink after washing.

This insulation does not absorb odors and moisture; excess moisture is easily released outside. Hollophan is resistant to bacteria, environmentally friendly and hypoallergenic.

Insulation Thinsulate

One of the best insulation materials created today is the advanced Thinsulate fabric, created for use in extreme conditions.

Thinsulate is a polyester material whose fibers are treated with silicone and twisted in a spiral. It is incredibly thin - the diameter of the fiber is much smaller than the diameter of a human hair. Thinsulate is called artificial swan down, but its warmth indicators are much higher than that of this organic prototype.

The fiber was developed by order of NASA, since its scope of application was to be space and the Arctic. A little later, the material began to be used to equip skiers. Today, this insulation has become the leader in popularity in professional and sportswear, as it can withstand the most extreme frosts, does not absorb moisture and is resistant to deformation.

In addition to excellent thermal conductivity, Thinsulate has one more feature - it is absolutely safe. Its use is recommended for allergy sufferers and newborns. Its area of application is the production of bedding, shoes, outerwear and haberdashery.

Holofiber insulation

Hollowfiber is a technological material made from many hollow fibers, thermally bonded. This elastic polyester fiber is as close as possible in terms of safety to organic materials, while possessing all the valuable characteristics of synthetics: versatility, strength and wear resistance. The owner of the Holofiber trademark and the manufacturer of the material is Moscow.

Among modern insulation and fillers, holofiber occupies a special place - a material that is the pride of Russian developers. It has been certified according to hygienic and environmental standards, which gives the right to use it in the production of children's products. But the scope of holofiber is not limited to this. Its main purpose is to serve as insulation. In terms of thermal insulation quality, this fabric is superior to padding polyester, batting and felt, which explains its popularity and the widest range of applications. It has been used for sewing army uniforms for 10 years now. Today, it is impossible to imagine the production of seasonal clothing, soft toys, blankets, pillows and furniture without holofiber.

Flytex insulation

Excellent warming material made in Belarus from polyester fiber. Tested in accordance with Oeko-Tex Standard 100. The special multi-layer structure allows for excellent thermoregulation. This insulation has a high degree of resistance to abrasion, bending and generally allows you to fold it as you like without compromising its quality characteristics. Resistant to repeated washing. It is light and compact. It is convenient to cut. Flytex is perfect for sewing everyday adult and children's clothing, as well as for the production of a various range of sports and special clothing (there is a brand of product that does not support combustion).

Thermofinn insulation

High-quality insulation, manufactured using Finnish technology by a responsible Russian manufacturer. The manufacturer of the product under the Thermofinn brand assures us that the quality management system in production meets all the requirements of ISO standards. “Termofinn” demonstrates excellent consumer characteristics and takes a worthy place among the brands of insulation that everyone knows:

- Has high-quality thermal properties

- Highly resistant to moisture

- wear-resistant

- Quite light and compact

- After multiple washes, shrinkage is only 0.2%

Important technical data:

- The following values are stated for thickness: 12 mm; 22 mm; 27 mm.

- The insulation has a density: 100 g/m²; 150 g/m²; 200 g/m².

- Maintains comfortable temperature conditions down to -30°C.

This filler is used for sewing all kinds of demi-season and winter types of outerwear for various purposes (sports, tourism, casual, children's and special-purpose uniforms), as well as for insulating a variety of related products.

Let’s add a couple more interesting ideas for “warming up” in inclement weather, which are undeservedly forgotten or their appearance on the market does not cause a loud stir:

Shelter fabric

When creating winter looks, it is not enough to focus only on the stylishness of clothing items. You definitely need to put together a couple of outfits that will easily protect you from the cold. In addition to apres with lunar rovers, it would be nice to get a down jacket or anarak with high-quality insulation. Modern matter shelter can easily play such a role.

This is a material that has a number of pleasant characteristics:

- Its fibers are thinner than similar materials. They stick together like a spider's web and don't bunch up when worn.

- Shelter fabric is soft, breathable, quickly takes on the required shape, increasing the comfort of movement.

- In its “compact” form, this material does not lose its excellent heat-shielding properties.

And the ability to become electrified is absolutely not typical for shelter fabric. Thanks to this, it is widely recommended for sewing, for example, ammunition for people working with flammable liquids.

Material Felt

Felt is a type of felt, the raw materials for which are natural or artificial fibers. Natural material is made from down and wool, while synthetic material is made from acrylic or polyester.

Natural felt is considered an environmentally friendly and safe material, has antibacterial properties and has high thermal conductivity. Regardless of its origin, this material is light, wear-resistant, does not crumble when cutting and is malleable in processing.

Its structure and appearance depend on the source raw materials. The surface can be fleecy, imitate suede or velor, or be smooth. Felt is used to make clothes, shoes and designer accessories that look impressive and appropriate in modern looks. This plastic canvas is an expressive tool for creativity - its bright colors are used in all kinds of applications and crafts. Felt is one of the best materials for needlework. This bright, soft and warm material will allow you to realize any design idea.

When caring, avoid high temperatures and intense spinning. Delicate handling will allow felt items to last a long time.

Of course, this list does not completely reflect the range that is currently presented on the insulation market. Our goal was to give a general idea of this product category. To try to convey to the consumer that padding polyester, batting, down and fur are far from the only fillers in your items. Modern materials are more compact, lighter, wear-resistant, support impeccable thermoregulation, do not cause allergic reactions, you can crumple them as you like, they are resistant to moisture.

Dear customers, if you ask sellers for products based on these insulation materials, there will be an offer.

Consumer reviews about care features

If you are interested in thermofin (insulation), you can read reviews about this material in the article. This material is easy to care for. It can even be dry cleaned. Products based on thermofin can be washed at temperatures within 30 degrees without the use of bulk detergents and bleaches. It is important to remember that in order to maintain a longer service life, it is important to avoid pressing, but clothes can undergo this stage in a gentle manner. If you have purchased clothing or a product based on thermofin-200 insulation, it is recommended that you read the reviews in advance. Consumers mention that it is recommended to dry such insulation away from heating devices. Those people who have been using this type of material for a long time note that products made from thermofin can warm a person even in the most severe frosts. If it is the basis of a pillow or blanket, then the products will be light, the rest will be serene and long.

Clean, wash, dry

The insulating material is very easy to clean. It can be dry cleaned. Products made from thermofinn are washed at a temperature of 30°C without the use of bulk detergents and bleaches. It is recommended to squeeze them gently. You need to dry things away from heating devices.

Read about: Ecofiber

This magnificent insulating material will keep you warm even in the most severe frosts. And your sleep on soft pillows under the lightest blanket filled with thermofinn will be long and serene.

Where to buy Certificates

| Termoreal LLC | 109316, Moscow, Volgogradsky prospect, 47, office 409 | Tel/Fax (general) |

© 2021 textiletrend.ru

Additional technical specifications

If you decide to purchase the described insulation material for your own needs, you should know that its density can vary from 100 to 200 grams per square meter. The intermediate value is a figure equal to 150. The canvas can have a thickness from 1.2 to 2.7 millimeters. The average value is 2.2 millimeters. Depending on what temperatures the insulation will need to protect from, it is worth choosing a material with a certain thickness and number of layers. Thus, the minimum temperature value can be -15 degrees. As for the lowest value, it is equivalent to -55 degrees. If you decide to purchase thermofin-300 insulation, reviews about it will be only positive. However, before purchasing, it is important to check whether the length, weight and thickness of the material in the roll correspond to those declared by the manufacturer. If the insulation is of high quality, then deviations from the above values should not be more than 2% of the declared ones. For comparison, you can use GOSTs, which allow deviations within 7%. The stability of the above-mentioned characteristics is beneficial in the process of calculating the quantity of purchased materials, as well as during its cutting.

Advantages of synthetic insulation

Nowadays, the bulk of clothing is made from synthetic fabrics, rather than from natural raw materials. Despite the fact that some women retain an unjustifiably biased attitude towards artificial materials, the fact remains: in terms of their heat-protective and performance characteristics, modern synthetic insulation materials are significantly superior to natural ones. They are more functional and guarantee comfort, beauty and safety in all weather conditions.

For example, with all the advantages of natural down, this material is capricious in production and care, wears out quickly, takes a very long time to dry and is a desirable habitat for various kinds of microorganisms. Wool is hypoallergenic, but can irritate the skin. It is subject to wear, shrinkage, is afraid of a humid environment and significantly weighs down clothing, which is why it is not used in sports equipment and clothing for active recreation, for which the weight and volume of products are of key importance. In addition, when wet, both down and wool almost completely lose their heat-protective properties. In conditions of high humidity, having very low hygroscopicity, air-filled synthetic insulation copes with thermal insulation much better.

Fashionable autumn coats, quilted with padding polyester

When choosing outerwear, every young lady is guided not only by the requirements of fashion, but also by purely practical considerations. A number of undeniable advantages are pushing the fair sex to increasingly prefer synthetic insulation:

- High heat retention

- Excellent breathability

- Low thermal conductivity of the fiber material

- High elasticity and mechanical strength

- Soft and elastic, no deformation

- Light weight and thickness

- Hygienic and hypoallergenic

- Wear resistance

- Easy to care for

- Fast drying

Reviews of some product properties

In the process of making warm clothes today, thermofin (insulation) is often used. To what temperature (reviews will help you understand) the material protects a person from the cold was mentioned above. This information will help you when purchasing products. However, it is also important to know that the material perfectly retains its shape and elasticity even after many washes, which is due to its structure. Due to the fact that biocomponent fibers consist of a polyester core and a low-melting shell, the material is a multi-fixed structure that is thermally stable. Users emphasize that after 5 washes the material shrinks by 0.2%, which is 10 times less compared to the parameters presented by state standards. This perfectly characterizes the material that was described above.