Kamila_Feodosya

5298 0 3

Kamila_Feodosya September 6, 2016Specialization: professional approach to architecture, design and construction of private houses and cottages, new products on the market of building materials and finishing. Hobbies: growing fruit trees and roses. Breeding rabbits for meat and decorative breeds.

The main advantage is ease of installation, but work must be performed in a respirator

Know-how in the modern building materials market is polyester insulation. Opinions regarding the benefits and advantages, as well as the safety of this insulation for a house or apartment, are radically divided.

Of course, production technologies are being improved literally every day, but is the high cost of this new product justified, and is it safe to insulate a living space with it? I tried to analyze the opinions of professional builders, chemists and technologists, as well as advertising materials from manufacturers.

Naturally, we make allowance for the fact that the manufacturer positions the product only from a positive point of view and exaggerates the advantages, carefully hiding the shortcomings.

Shelter insulation

The content of the article:

- Description and production

- Main varieties

- Specifications

- Advantages

- Flaws

- Criterias of choice

- Installation instructions

Shelter insulation is an environmentally friendly domestic heat insulator of a new generation. It is based on polyester fibers, which are glued together without the use of chemical compounds. The material is universal, has several varieties that can be used to insulate vertical, horizontal, inclined surfaces, as well as inter-crown gaps.

Features of modern polyester

Until recently, it was believed that clothing with synthetic insulation was in many ways inferior to products made from natural materials. The consumer's skepticism was well founded. After all, the polyester produced in the past easily wrinkled and caked, causing the product to lose its shape. In addition, the insulation quickly lost its thermal insulation qualities, and after the first wash the item became completely unusable.

The low quality of the material and the inability of the insulation to meet its intended purpose was explained by the structure of the material.

- In the past, polyester fiber was produced in the form of straight threads and placed in the same plane.

- Now polyester consists of fibers twisted into spirals, balls and tubes, inside of which there are air pockets.

Modern polyester is a light and warm material that perfectly copes with the role of insulation for demi-season and winter clothing.

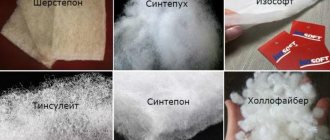

It is impossible to unequivocally answer the question of what temperature a synthetic filler is designed for. After all, the name “100% polyester” can hide Thinsulate, Holofiber, Sintepon, Isosoft and other materials based on polyester fiber. All of them have a certain density and structure, and therefore thermal conductivity.

Types of PE fiber insulation

Products under the ShelterEcoStroy brand of the Ves Mir factory are made from PE threads by heating with air. Construction insulation is not afraid of moisture, heat and frost, and retains its elasticity, shape and low thermal conductivity in any conditions. The material is hygienic and durable; the addition of fire retardants reduces the risk of fire.

It is easy to install and does not create discomfort for installers when cutting and installing. The insulation is effective on any part of the building: roof, walls, floor. Good vapor permeability allows use for wooden houses. Installation of the material is carried out on the lathing; it is similar to laying mineral wool, but does not require waterproofing.

Polytex is a new material on the insulation market. The products are produced by recycling plastic containers. In appearance and properties they are similar to holofiber. Polytex has become popular in Europe due to its properties: environmental friendliness, low hygroscopicity and heat transfer, resistance to biological organisms. The service life of the insulation is up to 50 years, during which time it does not reduce its characteristics.

To achieve fire safety, fire retardant additives are included in the composition.

Politex mats have a low density and minimal weight; they do not load the structure, but are superior to mineral wool in terms of heat retention capabilities. The material is vapor permeable and does not absorb water; when wet, the moisture quickly disappears.

Sintepon is an insulation made of organic fibers with a thermal conductivity coefficient of 0.031 W/m*K. In many respects it is close to basalt wool, but is an environmentally friendly and hypoallergenic product. Installation of thermal insulation can be carried out without special protection. Synthetic winterizer does not change its characteristics when wet, but due to its high breathability it requires the installation of a membrane.

AltEcoBud is a non-woven fabric made of polyester fibers used for thermal insulation of buildings, clothing and other products. The insulation contains no formaldehyde compounds and is environmentally friendly. The material reliably protects from frost and heat, is characterized by low water absorption and dimensional stability.

Among the advantages of AltEcobud: tensile and compressive strength, reusability, long service life, resistance to mold, fungi and insects. The insulation is recommended for insulating floors, walls and ceilings made of any material: wood, brick, concrete. It is used as filler in frame structures.

Polyester insulation

This material is made from modified polyester fibers. To give it the desired properties, flame retardants and other additives are added to the composition. Insulation made from polyester fibers has low thermal conductivity and is light weight. This allows you to organize effective protection against heat loss without overloading the building structure. Polyester insulation is an environmentally friendly material because it does not contain phenol, formaldehyde and other harmful compounds.

Most often, polyester fibers are used to insulate clothing, fill pillows, blankets, mattresses, furniture and car seats. It is a hollow spiral-shaped fiber that springs well. The fibers are held together by hot air. In practice, it is 100% polyester. It easily restores its structure after compression. It is produced from used PET bottles or from melted polyethylene terephthalate (PET). Today, polyester fibers are increasingly used in construction for insulation of various structures.

Polyester fibers have exclusive properties that are superior to other types of thermal insulation in many respects. This material: has a thermal conductivity coefficient of 0.033; fits perfectly to objects of any shape and can be used in the most difficult to reach places; unable to absorb moisture; has great tensile and compressive strength; is the thinnest sound insulation in the world; when heated, it does not emit harmful substances, does not have its own odor and does not absorb foreign substances; the most environmentally friendly insulation today, because it does not contain formaldehyde compounds and adhesives; does not promote rodent breeding; not affected by microorganisms, mold, fungi; does not generate dust or pollute the air; completely chemically inert; has good vapor permeability; does not cause allergies; has an antistatic effect; resistant to solvents; weighs very little - even less than polystyrene foam or extruded polystyrene foam; can be reused; does not require protective equipment during installation work; you can install mats or attach insulation in rolls without any special skills; serves for more than 50 years without losing its original properties. Polyester fibers have a high fire resistance because they are treated with a fire retardant. When exposed to open fire, they melt, but do not allow a real flame to break out. There are many videos on the Internet demonstrating the fire-resistant properties of insulation. Selection of polyester fiber. The insulation is sold in rolls and mats, which vary in thickness - 40 mm and 50 mm. With this material, even small fragments do not fall apart.

The scope of application of polyester fiber is enormous. This is insulation and sound insulation: frame houses made of sandwich panels; roofs with rafters, suspended ceilings, floors, interfloor ceilings and

multilayer walls of houses made of timber, saunas and baths; interior partitions and external armored doors; refrigeration chambers; car salons. This unique insulation is created using nanotechnology. There are 7 types of polyester fibers, but it is the hollow ones that are used for thermal insulation materials. The main and only drawback of insulation is its fairly high cost. However, the majority of polyester fiber produced in the Russian Federation is supplied directly to construction and engineering organizations and very little goes on sale. In Europe, the USA and Japan, this type of thermal insulation is in great demand among individual developers. Due to its low weight, it reduces the load on supporting structures.

Polyester insulation: pros and cons

Until recently, many people doubted whether synthetic jackets were warm or not. We can agree with the skeptics, because natural fur and other materials of natural origin were denser and more reliable than polyester, which was used as insulation.

The raw materials that were produced earlier easily wrinkled and lost their shape. In addition, it lost its thermal insulation properties, and when washed it became completely unsuitable for wear.

Experts compared what the material was like in the past and what it has become now:

- Previously, polyester fibers looked like straight threads running in one direction. This may explain poor thermal insulation and other shortcomings.

- The new polyester is made from fiber that is twisted into spirals, made in the form of balls, in the shape of cylinders. They have air pockets inside. The layer retains heat well and is very lightweight.

At first glance, it is difficult to say what temperature conditions a synthetic item is designed for. If the tag says “100% polyester,” this may mean that the insulation is made from synthetic fluff, isosoft, or other raw materials based on polyester fibers. They differ in their density, which also affects how they retain heat. It all depends on how the padding is made: the threads can be woven in different ways, and sometimes manufacturers add additional structures.

Polyester has many properties:

- The temperature range at which polyester filling can be worn is from 5 to 30 degrees below zero.

- Clothing with synthetic insulation does not harbor pathogenic bacteria, so even allergy sufferers can wear it.

- Things retain their original shape for a long time and are not subject to deformation after many washes.

- The jacket's filling does not require special care; it is easy to wash in an automatic machine.

- Down jackets weigh little, making them comfortable for people of all ages.

However, at temperatures above 40 degrees Celsius, the fibers become deformed. Inexpensive material may become crumpled after 3-4 washes. In addition, air does not circulate well through such material. The insulating layer is deformed upon contact with fuel, acetone and other compounds containing caustic components.

How to care for clothes with polyester filling?

Whatever the insulation, it requires special care. How the insulated product is washed, dried and ironed directly determines its thermal insulation properties. If you properly care for warm clothing, strictly following all the manufacturer’s recommendations, you can not only preserve its original qualities, but also extend its service life. Caring for a product with polyester insulation involves following the following recommendations:

- Wash by hand or in a washing machine. If a product is allowed to be washed, this does not mean that it can be done every day. This should only be done when it becomes dirty. No matter how high-quality and wear-resistant the insulation is, frequent washing will sooner or later lead not to loss, but to a significant reduction in its thermal insulation qualities.

- When washing in the washing machine, place several tennis balls in the drum. This measure will prevent possible dumping of the filler.

- Before washing, treat heavily soiled items with stain remover and soak for 25-30 minutes. It is not recommended to use chemical bleaches to remove stains.

- When washing automatically, select the delicate cycle.

Wash in water whose temperature does not exceed 40°C, using mild detergents. It is better to use gels. The powder may not be rinsed out, which will lead to the formation of white streaks on the surface of the product.

It doesn’t matter what brand the detergent is, the main thing is that it does not contain aggressive components. When spinning in a washing machine, set a mode in which the number of revolutions does not exceed 800.

- Dry flat in a well-ventilated area away from heating devices. You also need to ensure that the product is not exposed to direct sunlight.

- Iron only if necessary with a not too hot iron. It is recommended to use an ironing iron. You can steam clothes made of polyester only if the manufacturer allows it.

Such products should not be boiled or exposed to high temperatures. Otherwise, this will lead to disruption of the structure of the polyester fiber and deformation of the product.

What are polyester insulation

These are thermal insulation materials used at various stages of repairs and house construction. The material is produced by thermal bonding of polyester fibers without adhesives.

The insulation thread is similar to a spiral and consists of many intertwined fibers that “spring”. It is this feature that almost prevents the canvas from deforming, maintaining its elastic properties.

In essence, polyester insulation is a synthetic but environmentally friendly textile. The same PE fibers are used to fill pillows, blankets, carpets, children's mattresses, jackets, and toys. The difference may only be in the thickness of the threads and other characteristics that are insignificant for the user.

Advantages of polyester insulation

The special thread has the shape of a small spiral and consists of a large number of intertwined fibers. It is the springy structure of the fiber that gives the polyester material the most valuable technical characteristics for use in everyday life and industry.

The particularly valuable properties of the material include high strength, resistance to deformation, low weight, low susceptibility to sudden temperature changes, low thermal conductivity and a fairly long service life.

Application of PE insulation

One of the important construction processes during the construction of residential and industrial buildings is carrying out high-quality work on insulating objects. To do this, first of all, you need a high-quality, durable, lightweight and most productive thermal insulation layer. PE insulation has all these qualities.

Positive features of use:

- There is a real possibility of significantly reducing the heat transfer of room partitions without loading the entire structure.

- The fibers have increased moisture-repellent properties. At high humidity, they do not change their physical properties and quality characteristics.

- Insulation is an environmentally friendly product, therefore, when heated, it is not capable of polluting the atmosphere with substances harmful to human life.

- The material has a fairly long service life, is resistant to external influences and is practically not susceptible to deformation.

- Polyester insulation is fireproof. If a fire occurs, the material reacts poorly to a sharp increase in temperature in the building.

- The material has sound and noise insulating qualities, which allows it to be used in rooms with high noise levels.

- Polyester fiber is not susceptible to infection by mold or mildew and reacts poorly to treatment with household chemicals.

- Unlike other widely used thermal insulation materials, PE does not irritate human skin during installation.

Due to their positive qualities, various types of insulating and sound-absorbing materials based on polyester fibers are widely used during construction or finishing work.

Various modern materials are produced from PE fibers:

- Holofiber. It is used not only as an insulating material, but also for filling the insides of pillows or blankets.

- Polytex. The insulation material is the result of recycling already used plastic containers.

Modern insulation materials do not lose their original shape and volume, which helps ensure the highest quality thermal insulation of the entire living space.

Stages of insulation production

The first polyester threads were created at the end of the last century, but since that time the polyester material has been modified several times, constantly changing its chemical composition and improving technical characteristics.

For the production of modern insulation materials, only high-quality primary raw materials and the latest materials are used. All products manufactured at the factories undergo special certification, which indicates the conclusion of chemical laboratories on the air permeability, level of heat transfer and breaking load of the product.

Area of use

The versatility of the material allows it to be used in a wide variety of household and industrial areas:

- in light industry: for the production of beautiful artificial fur or synthetic carpets;

- in construction: as a reliable and durable insulation in frame walls of a building, interior partitions of baths and saunas;

- in the construction of pipelines: the material is used in particularly extreme climatic conditions.

To all of the above, we can add quite specific areas in which PE material is successfully used: reinforcement of rubber products or the production of special equipment for a pulp and paper mill.

Today there are combined versions of polyester fibers. In addition to introducing various chemical elements into the raw material, there are options for combining PE fibers with other synthetic or natural threads.

To create the most durable and reliable insulation materials in production, cotton and jute plant fiber are added to the raw materials. Raw materials of animal origin, such as sheep or camel wool, are added to the combined materials.

I recommend watching

Opinions of developers, professional builders and chemists - negative points

Types of modern insulation

I found an interesting article on a website on labor protection in the chemical industry. The influence of polyester resin on the human body and safety measures at work are being studied. What they warn about:

- Polyester resin bonds the fibers together to provide water-repellent and strength properties. When working with resins, safety precautions must be observed. Does this resin disappear or remain in the finished building material? Manufacturers do not answer this question.

- Polyester resins cause respiratory irritation. It is mandatory to wear a respirator when working in production. When the insulation is heated, do resin vapors not escape from the sheathing?

Production volumes speak volumes

- Fire safety - with free access to air and sunlight, spontaneous combustion is possible. You cannot extinguish the resin with water; you can only intensify the combustion. A gas fire extinguishing method is required. This means that fire retardants are obviously added to the insulation to ensure G-1 flammability standards, and these are chemical additives.

- If the resin gets on the skin, the instructions warn about the danger of redness and rash. It is necessary to urgently rinse with water, work in gloves and protective shoes and overalls. Why, since these insulating materials are easy to install and are not hazardous to health?

- Polyester resin is a strong irritant to the mucous membranes. Wear safety glasses. The question arises - where do these resins disappear from completely safe polyester insulation?

Main technical characteristics of the material

It is not surprising that it is difficult to find information about the production process of this building material. Protection of production know-how and other reasoned methods to hide the detailed composition of the material.

A few words about static electricity

Are static discharges really safe?

Polyester fiber is a dielectric and practically does not conduct electric current. That is why the surface of such a material quickly becomes electrified. Everyone is familiar with the tiny sparks in the dark when you take off synthetic clothing.

It is this property that is inherent in all polyesters. Static electricity accumulates on the surface.

The impact of static electricity on health is the topic of a separate dissertation. Basically, these are fatigue, absent-mindedness, and weakness. And long-term exposure causes a number of serious side effects. If you wish, you can find a lot of information about this on the Internet.

Now the question is whether polyester fiber insulation has the same properties to accumulate static on the surface. Has this been studied in laboratories, and what consequences can a long-term stay in a house with such insulation cause?

I will not say that polystyrene foam or mineral wool will do absolutely no harm. But at least the mineral wool boards are natural fibers and not recycled plastic bottles.

Another interesting fact. Is it possible to position this material as natural if it is made from PET bottles?

Of course, ideally, everyone strives for environmental friendliness and natural materials, but they are not affordable for everyone. But why is the cost of synthetic material equal, or even higher, than for natural types of insulation? In theory, polyester fibers should cost pennies.

Polyester insulation: a “warm coat” for your home

Modern insulation made from polyester fibers will help maintain home comfort even in the most severe frosts.

What is home comfort usually associated with? Of course, with warmth! In winter clothing, modern fillers based on polyester threads, which reproduce the structure and properties of fur, help preserve it. Manufacturers have adopted their best properties and entered the market with new insulation materials.

Polyester fibers - what are they?

Scientists became interested in the use of polyester for the production of high-quality and inexpensive insulation materials back in the 80s of the twentieth century. Experiments continue to this day: specialists are developing new combinations of materials and improving the quality of the final product.

For production, the polyethylene terephthalate melt is drawn through special molds - dies. The result is fibers - parallel or multidirectional, which become the basis of the primary fabric. Next, a multi-stage processing process begins - combing, cutting, mixing, bending, twisting, adding antistatic agents and other procedures. As a result, the fibers acquire final consumer properties.

Polyester fibers can be of different thicknesses, densities, textures, and types of twist, which gives the material its individuality and allows it to be used in different industries. Today, polyester insulation is most widely used in construction and light industry (clothing). In terms of popularity, they are not inferior to traditional materials made from natural and synthetic raw materials, and in many respects they significantly surpass them.

Advantages

The first thing that worries a buyer when choosing insulation for a home is the thermal conductivity coefficient: the lower it is, the less heat is consumed. So, for polyester materials, due to their high porosity, this indicator is 0.029–0.031 W/(m * °C). For comparison: for mineral wool, depending on the type (basalt, slag, stone), this coefficient varies from 0.041 to 0.052 W/(m * °C).

Polyester insulation - where and how to use

The main purpose of insulation is to serve as a protective barrier against heat loss. With the advent of technology, synthetic-based materials have appeared that are superior in their subtleties to real products, and their affordable cost is often the decisive factor in choice.

Production of polyester fibers

Experiments with polyester (PE) threads began in the 80s, but until now pundits have been creating different combinations of raw materials based on chemistry in order to achieve better properties of the final product. Excellent fiber is the basis of good insulation, as a result of which every stage of production is controlled in factories.

The main parameters of threads that affect the characteristics of the product are thickness, type of twist, uniformity and density. Any change in them leads to the production of material with new qualities. The plastic structure of the fibers adds elasticity, tensile and compression resistance to the insulation.

Characteristics and features of polyester products

Polyester insulation is an affordable alternative to mineral wool. It stores all the operating parameters of the material, and is made of organic matter. Polyester threads will not break during installation, like glass or stone fibers, and dust that is caustic and harmful to humans will not be created.

It does not contain binders with phenol or formaldehyde; during the heating process, polyester

the insulator does not emit toxic fumes.

Low water absorption, not exceeding 1% of the volume, allows you to use a heat insulator and store it without protection from moisture. When water hits the product, it flows across the surface, leaving the layers in the middle dry. This property allows you not to worry about the safety of the insulated structures - metal under the polyester material does not corrode, and wood does not rot. Elastic fiber bends easily and facilitates installation on a curved surface. The insulation is laid with a minimum of waste; it does not separate into some parts like mineral wool.

Polyester fiber insulation

Polyester fiber insulation is created using the technology of thermal bonding of polyester threads, without adding any other substances, including adhesives. The first padding polyester products included adhesive additives, but more advanced holofiber does not contain anything except polyester threads twisted in a special way like springs. Considering the absolute environmental safety of PE products (it’s not for nothing that children’s mattresses and pillows are made from them), polyester insulation can be considered a worthy alternative to natural ones. Inside the house and outside, in the interior and when cutting a cobblestone or log house - PE insulation has a reputation as absolutely safe materials.

Construction holofiber

PE threads and the insulation materials created from them have their origins in textile technologies (fillers for warm winter clothes, blankets, and so on). But a building board is a much denser and “rougher” thing compared to a children’s air mattress, and therefore is made from thick and dense PE threads, although the predominant twist is spiral, as in holofiber.

The main advantages of polyester insulation:

- Excellent sound insulation. An attic with PE insulation becomes the quietest place in the house; you can’t even hear the rain on the roof.

- According to the main parameter of insulation: the thermal conductivity coefficient of PE materials Kt = 0.029 - 0.031 W/m*deg K, which is slightly better than that of mineral wool.

- Vapor permeability.

- Frost resistance. Low water absorption (less than 1%) gives both the advantage of frost resistance and the ability to store rolls under light cover.

- Does not create cold bridges. One of the few mounted insulation materials that create an almost monolithic coating without equipment for foam, blowing, etc.

- Biostability is absolute, fungus and mold are impossible. Does not contribute to wood rotting due to accidental moisture and corrosion of metal elements.

- Good tensile and compressive strength, elastic properties.

- Environmental safety, hypoallergenic insulation, can be used both indoors and in children's rooms.

- Light weight, easy to use, virtually no waste.

- It is safe to install - it does not generate dust, it fits equally well on any surface, at any angle.

Polyester inter-crown insulation

Intercrown holofiber is called a new generation of insulation. Depending on the type of felling, tape and roll holofiber are used. Installation is extremely simple, the light and airy insulation literally fits itself into the joints and gaps and perfectly fills the voids. But with all the advantages of PE insulation, it has not yet passed the final test of time.

Fire retardant is justifiably added to insulation for wooden houses, which reduces environmental characteristics. From reviews of private builders, it can be noted that there are cases of changes in the color of debarked logs, and sometimes blackening is observed at the joints. In addition, PE insulation is far from the cheapest material.

Production of polyester insulation

Polyester insulation is the material of the future, despite the fact that the first polyester threads were obtained in the 80s, it can be endlessly modified by manipulating the chemical composition of the raw materials and obtaining new properties.

For its production, only high-quality primary raw materials are used. It undergoes a quality control procedure at all stages of fiber production. At factories, specialists carefully monitor how uniform the fiber is, what thickness and density it has.

The production of PE insulation implies compliance with technical conditions and established standards. Products require mandatory certification, therefore they have documents confirming the completion of this procedure, as well as a quality certificate and conclusions of accredited laboratories. They indicate the level of heat transfer, air tightness, breaking load, and fiber migration.

Thermal insulation material based on polyester threads and fibers is sold in packaging. Packaging comes in different sizes and weights; there are no standardized options - this is done for ease of use, focusing on customer demand.

Advantages

The first thing that worries a buyer when choosing insulation for a home is the thermal conductivity coefficient: the lower it is, the less heat is consumed. So, for polyester materials, due to their high porosity, this indicator is 0.029–0.031 W/(m * °C). For comparison: for mineral wool, depending on the type (basalt, slag, stone), this coefficient varies from 0.041 to 0.052 W/(m * °C).

Advantages of Lighttek and Shelster Ecostroy insulation materials

To produce these insulating materials, polyester fiber is used. Polyester is actively used in our lives to create dishes, water containers, furniture, insulation for clothes, toys, etc. Now polyester fiber is also used to insulate their homes.

The advantages of Lighttek and Shelster Ecostroy insulation are as follows:

- Environmental friendliness and safety.

- High quality.

- Elasticity. Polyester fibers are long and elastic. They do not break when mechanically applied to them, and have a certain spring effect.

- Flexibility. These materials can be used to insulate places that are difficult to reach.

- Not afraid of contact with moisture. If polyester insulation gets wet, after drying all the characteristics and their dimensions will be restored again. If, for example, glass wool insulation gets wet, it will be impossible to use it in the future as insulation.

Unlike other modern thermal insulation products, polyester fiber insulation has a number of advantages:

- Ecologically pure;

- High levels of protection from noise and cold;

- It is not subject to deformation, which significantly extends its service life;

- The density and elasticity of the material facilitates the installation process;

- Does not absorb moisture;

- Durable and has unlimited use;

- Can be used repeatedly;

- Easy to use (no special protective equipment required);

- Resistant to mold and mildew.

Due to its qualities and resistance to negative factors, polyester insulation is widely used in almost all areas of construction. We produce several types of thermal insulation from polyester fiber, which differ in their parameters and are ideal for insulating a particular surface.

RosEcoMat Polyef Horizon

This insulation consists of hemp and polyester fibers.

Application: Thanks to the natural antiseptic in the composition, this type is suitable for insulation and insulation of interfloor ceilings and floors. Hemp fiber prevents rotting processes.

Specifications

| Parameter | Unit measurements | Characteristic |

| Length | mm | 1200 |

| Width | mm | 600 |

| Thickness | mm | 50/100 |

| Slabs in packaging | PC | 10/5 |

| Packaging volume | m3 | 0,36 |

| Packing area | m2 | 7,2/3,6 |

| Bulk Density | kg/m3 | 10 kg/m3 |

| Thermal conductivity | W/mK | 0.034 |

RosEcoMat Polyef Vertical

This insulation will become an indispensable material, since installation does not require special skills.

Application: Insulation is used for thermal insulation of frame walls and interior partitions. The structure of the board allows it to absorb sound well and prevents the formation of condensation and mold. The natural component (hemp fibers) reliably protects surfaces from the effects of negative factors.

Specifications

| Parameter | Unit measurements | Characteristic |

| Length | mm | 1200 |

| Width | mm | 600 |

| Thickness | mm | 50/100 |

| Slabs in packaging | PC | 10/5 |

| Packaging volume | m3 | 0,36 |

| Packing area | m2 | 7,2/3,6 |

| Bulk Density | kg/m3 | 20 kg/m3 |

| Thermal conductivity | W/mK | 0.036 |

RosEcoMat Polyef Slope

This material is actively used in construction.

Application: The very name of the insulation indicates that this material’s parameters are ideal for insulating attic roofs and roofs. The insulation also copes well with the problem of heat and sound insulation of floors on wooden beams. RosEcoMat Polyef Slope can be used and is suitable for insulating from sounds outside the house, such as the sound of rain or sounds from passing vehicles.

Specifications

| Parameter | Unit measurements | Characteristic |

| Length | mm | 1200 |

| Width | mm | 600 |

| Thickness | mm | 50/100 |

| Slabs in packaging | PC | 10/5 |

| Packaging volume | m3 | 0,36 |

| Packing area | m2 | 7,2/3,6 |

| Bulk Density | kg/m3 | 16 kg/m3 |

| Thermal conductivity | W/mK | 0.033 |

RosEcoMat Polyef Antisound

Hemp is antibacterial and works great against mold and mildew problems.

The polyester composition does not absorb moisture, so condensation and surface deformation are excluded. Application: The parameters of this type of polyester insulation are designed specifically for soundproofing premises (interior partitions and floors). In addition to polyester fiber, the board contains hemp fiber. It is this composition that makes it possible to safely use this type of building insulation in residential premises.

Specifications

| Parameter | Unit measurements | Characteristic |

| Length | mm | 1200 |

| Width | mm | 600 |

| Thickness | mm | 50/100 |

| Slabs in packaging | PC | 10/5 |

| Packaging volume | m3 | 0,36 |

| Packing area | m2 | 7,2/3,6 |

| Bulk Density | kg/m3 | 20 kg/m3 |

| Sound absorption coefficient | 0,98 |

RosEcoMat Polyef Roll

RosEcoMat Polyef Roll is an insulation material produced in rolls, which is convenient for installation, especially during the construction of low-rise residential buildings.

Application: Safe insulation made from hemp and polyester fibers is environmentally friendly, which is perfect for insulating residential buildings, as well as insulating saunas and baths. Due to its increased environmental friendliness, this insulation is often used in medical and children's institutions. The service life of the material is up to 150 years, and due to the high energy savings, you can save a lot on your purchase.

Specifications

| Parameter | Unit measurements | Characteristic |

| Length | mm | 6000 |

| Width | mm | 1200 |

| Thickness | mm | 50 |

| Packaging volume | m3 | 0,36 |

| Packing area | m2 | 7,2 |

| Thermal conductivity | W/mK | 0.036 |

| Specific heat | J/kg K | 1550-1600 |

| Sound absorption coefficient | NSV-211 | |

| Coeff. vapor permeability | mg/(MhPa) | 0,33-0,37 |

| Compressive strength | kPa | 1-2 |

Insulation made from polyester fibers from the best domestic manufacturer RosEcoMat is a contribution to the comfortable atmosphere of your home and concern for the health of your loved ones.