Sintepon

Sintepon is made from polyester fibers. The material was developed in England in 1935. Since then, fused thermoplastic fibers have been used not only in their pure form, but also in combination with natural materials: threads of cotton, wool or bamboo.

Under a microscope, padding polyester fibers look like many spirals or springs intertwined with each other.

This material turned out to be an excellent replacement for natural insulation materials - feather, down and wool. Synthetic winterizer is much more practical than natural ones because:

- easy;

- retains heat for a long time;

- does not deform under compression;

- it can be washed in a machine;

- dries quickly;

- does not absorb moisture and sweat;

- it does not harbor feather mites and fungus;

- hypoallergenic material;

- affordable.

What is the difference between padding polyester and holofiber

In principle, the material is made from the same fiber, but using different technologies. Sintepon is a type of silicone fiber, like holofiber, but all the fibers in it are glued. In holofiber, the threads are connected to each other by soldering at high temperatures without the use of glue. There is emptiness inside the fibers, which makes the material light and very warm. Thus, holofiber is much lighter and warmer than padding polyester.

It is not always clear to consumers what is better: padding polyester or holofiber. The latter is a material that looks like small lumps of cotton wool and poplar fluff. Adhesion between individual fibers is achieved through thermal action.

Holofiber

The industry produces synthetic winterizer in the form of layers with a thickness of 1.5 to 15 cm. The thickness of the material intended for the manufacture of warm clothing is 1.5-2 cm. Blankets are sewn from fabrics of greater thickness with a width of 2.2 m. Sold by the meter.

Both types of nonwoven materials are made from synthetic raw materials. Sintepon is produced longer than holofiber. Its manufacturing technology is based on gluing polyester fibers. Holofiber lumps consist of twisted fibers in the form of miniature springs.

Recycled waste is used to produce padding polyester. Glue is used to glue the fibers together. All together affects the environmental friendliness of the material.

Sintepon

Note! Frequent washing is contraindicated for sintepon; under the influence of water, the material is destroyed and deformed. During the operation of the finished product, individual sections of the padding polyester fabric cake and lose their quality. Therefore, padding polyester stitch is used for the lining.

Holofiber does not wrinkle; after compression, it quickly takes its previous shape. Washing does not in any way affect the quality and wear resistance of this material. The filler is sold by weight. It is easy to distinguish both materials by appearance and touch.

Synthetic stitch

Holofiber

Insulation made of 100% polyester hollow structure. The material is produced in the form of balls or webs consisting of tightly twisted spirals. The air between the holofiber microparticles heats up quickly and retains heat for a very long time. At the same time, sufficient air flow is ensured and the body in such clothes does not overheat.

Holofiber appeared later than padding polyester, but at the moment it is more in demand among clothing manufacturers because:

- air circulates better between the particles of the material;

- does not absorb moisture;

- holds dust on the surface, preventing it from penetrating inside;

- the filler does not absorb odors;

- retains its shape;

- does not ignite;

- dries quickly;

- Machine washable;

- acceptable price.

Caring for synthetic insulation

Modern synthetic materials make it possible even for people with a modest budget to dress beautifully, comfortably and modernly. This also applies to down jackets.

they can retain heat better;

some of them allow you to feel comfortable, even if a thaw suddenly sets in after the morning frost;

they are easy to wash and dry;

many of them do not go astray over time, so there is no need to pat clothes;

among artificial fillers there are those that can last for decades.

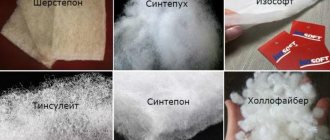

padding polyester;

synthetic fluff;

isosoft;

holofiber;

Thinsulate.

New materials appear every year, so don't be surprised if you see a different name on the label. But so far these remain the most popular.

Synthetic items do not tolerate hot water well. They cannot be ironed. If necessary, they are treated with steam. To avoid unnecessary ironing, during the process of sewing blankets and blanket-type bedspreads, the fabrics must be ironed.

According to the technology, the parts of the products are sewn face to face and then turned inside out. The edges of a half-finished item cannot be ironed, otherwise the internal synthetic filler under the influence of high temperatures will wrinkle and lose volume.

The edges of blankets and bedspreads are swept along the entire perimeter, and then ground down with a finishing stitch.

Products are stuffed with filler

What filling for jackets and promotional vests is most often preferred?

A draft at the cash register, or constant movement from the premises to the terrace of a restaurant or cafe can provoke ARVI among staff. It is better to equip employees with suitable clothing in advance than to urgently look for someone to “plug holes” in the work schedule.

Ask a Question

People most often order holofiber vests from us and argue that:

- the material is inexpensive;

- easy;

- perfectly warms;

- and also does not absorb odors, which is important, because clothes smelling in the smoking room will spread a stale smell.

Sintepon is inferior in quality to holofiber; it:

- electrified;

- worse air permeability;

- can absorb unpleasant odors;

- warms better than natural materials, but worse than holofiber.

Usually, workwear made from holofiber, including jackets and vests, is dry-cleaned, but washing it yourself in a machine at a temperature of 30°C is acceptable and will not harm the product.

It is important to take into account temperature standards, because the density of the holofiber determines at what temperature it will be most effective.

| Holofiber density | Minimum operating temperature | Maximum operating temperature |

| 100 g/m2 | +5°С | +10°С |

| 150 g/m2 | -10°С | +5°С |

| 200 g/m2 | -20°С | -10°С |

| 300 g/m2 | -30°С | -20°С |

What is synthetic fluff?

Synthetic down is an artificial non-woven insulation created on the basis of polyesters. It consists of many tiny polyester fibers, each of which has hollow spaces filled with air. This structure gives the material lightness, water resistance and thermal insulation qualities.

Pillows are also stuffed with synthetic down.

There are several types of insulation depending on the linear density. They can be distinguished from each other by marks on the thickness (from D7 to D15) and length (3.2-3.6 cm) of the villi.

The characteristics of synthetic down resemble natural down.

Due to its properties, synthetic fluff is used in many areas.

- Density. The insulation fibers are quite strong, resistant to moisture and heat. Therefore, the material does not lose shape and volume after washing or manual processing.

- Water resistance. This quality is ensured by artificial silicone impregnation. Thanks to it, the material repels moisture, preventing it from penetrating inside, and dries faster after washing.

- Ability to keep in shape. The insulation fibers are smooth and difficult to tangle or crumple. Therefore, the material is resistant to deformation and quickly restores its shape, which is especially useful when stuffing blankets, pillows, soft toys, etc.

- Thermal insulation. In the structure of synthetic down you can find a large number of hollow spaces filled with air, due to which the material provides thermal insulation. The air gaps are extremely small, and water cannot penetrate into them, due to which this property is maintained even when wet.

The exact characteristics of the material depend on the length and thickness of the pile. Insulation with long fibers is softer but less durable, so it is often used to fill pillows and blankets. Material with thick pile holds its shape better, but is characterized by increased rigidity, which is why it cannot fill all the narrow spaces in the printed part.

Due to the hypoallergenic nature of the material, it is actively used in the production of bedding.

- Ecological cleanliness. Synthetic fluff is completely safe for the environment; no harmful substances or reagents are used in its production.

- Safety. Unlike natural down, artificial insulation is completely hypoallergenic. Dust does not accumulate in it. Additional antibacterial treatment prevents the formation of fungus, and antistatic treatment prevents the accumulation of electricity. All this makes synthetic down a good material for sewing products for children, pregnant women, allergy sufferers and the sick.

- Breathability. The presence of air cavities not only helps to retain heat better, but also allows clothes to breathe, so they do not irritate the skin. In addition, air circulation allows faux down items to dry faster and stay wet longer.

- Weather resistant. Like natural down, its synthetic counterpart does not lose its warming and protective properties even in extreme conditions. The material retains thermal insulation characteristics at temperatures down to -30 °C and wind speeds of 15 m/sec.

- Ability to maintain shape. Unlike its natural counterpart, synthetic fluff never clumps. It does not shrink after washing and quickly regains its shape when stretched or compressed.

- Easy to care for. The material is unpretentious and withstands both dry cleaning and hand and machine washing. Products with it have an unlimited service life, unlike things with natural down.

- Odor resistance. The filler is wrapped in a silicone coating, which prevents the absorption of foreign odors.

- Ease. Most of the insulation is occupied by air gaps, so it is light in weight and does not weigh down clothing.

- Comfort. Soft, fluffy synthetic fleece is pleasant to the touch. Products made from it are comfortable to wear on the body and use in everyday life.

- Low price. The material is cheaper than natural down and has similar or superior characteristics.

The only drawback of artificial insulation is that it does not withstand too frequent washing. They lead to a rapid loss of the thermal insulation properties of the filler.

Synthetic fluff does not tolerate frequent washing.

- the seal is made without formaldehyde, glue and other potentially toxic materials, so it does not emit anything even when stored in unsuitable conditions;

- the insulation contains no dyes, fragrances or other harmful substances;

- the structure of the fibers allows the material not to irritate human skin even with direct contact;

- Synthetic fluff does not cause allergies or other intolerance reactions;

- the insulation fibers are treated with an antibacterial compound, so fungus and mold do not appear on it when wet;

- Unlike natural fillers, synthetic down cannot serve as a home for parasites such as bedbugs and dust mites - its structure is too dense, and chemical treatment additionally repels insects.

The safety of synthetic fluff has been confirmed by numerous tests. Therefore, it is widely used in the production of children's clothing, bedding, toys, etc.

Where is it used?

Synthetic down is used as insulation and sealant.

Due to its price, synthetic fluff is a favorite filler for toys.

Main areas of application:

- production of winter and demi-season clothing: warm hats, mittens, jackets, coats, down jackets, raincoats, etc.;

- insulation of sleeping and decorative pillows and blankets;

- stuffing upholstered furniture, sealing protective covers for it;

- production of mattresses, backs, seats, sides, armrests;

- compaction and insulation of items of tourist equipment (sleeping bags, tents, etc.);

- sewing carpets;

- stuffing toys;

- needlework.

We suggest you familiarize yourself with How to wash a felt-tip pen from a child’s skin

In addition to the textile and furniture industries, synthetic fluff is often used in construction. Gaskets made from it help enhance the heat and sound insulation of walls, floors, and ceilings. In addition, air filters and similar parts are made from the material.

Sintepon differs from synthetic down in the structure of its fibers. They are made entirely of polyester and do not contain air gaps. In addition, recycled products and adhesive emulsion are used in the production of padding polyester.

There are different types of synthetic fibers.

This explains the main differences between the material:

- synthetic winterizer can be harmful to the body due to the content of glue and esters;

- the material has a shorter service life;

- when wet, it quickly loses its shape, therefore it is not suitable for wearing in rain and snow, and is also poorly resistant to washing and loses its thermal insulation qualities after several cleanings;

- due to the lack of air spaces, synthetic winterizer retains heat worse (it can withstand cold down to -15 °C compared to -25...-30 °C for synthetic down);

- the material is flimsy, easily crumples when washed, and is poorly resistant to deformation;

- synthetic winterizer has poor breathability, so it easily absorbs odors and does not allow the skin under clothing to breathe;

- the material is poorly resistant to temperatures and can only withstand gentle washing, so it is more difficult to care for products made from it;

- synthetic fibers are less durable - the fibers often come off, forming lumps and getting tangled.

The only advantage of padding polyester is its low price. It is considered an obsolete material, so it is practically not used in the manufacture of high-quality clothing.

The only difference between the materials is the production technology. Holofiber fibers are twisted into balls, and synthetic fluff into springs.

This explains the difference in the quality of insulation:

- holofiber is less resistant to heat and moisture, therefore it requires gentle washing and is more difficult to care for;

- holofiber is heavier and denser than synthetic down, which is why it is more often used in construction and industry, but less often in clothing;

- Synthetic fluff costs a little more due to more complex manufacturing technology;

- Holofiber retains dirt and dust better due to its denser structure, which makes it possible to use it in the manufacture of filters.

Unlike padding polyester, holofiber is similar in characteristics to synthetic down and can compete with it. The choice of material depends on the purpose of its use.

Rules for caring for products made from synthetic down:

- The material can be machine and hand washed. It can withstand temperatures up to 90 °C. When cleaning items of clothing made from several types of fabric, you need to choose the appropriate mode for the most sensitive and delicate of them.

- Large, bulky items (jackets, coats, raincoats) must be washed separately.

- You need to check the fabric and lining for holes and loose seams. If they are present, the product can only be washed on a gentle cycle at a temperature of 30... 40 °C to prevent further damage.

- Areas particularly susceptible to contamination (sleeves, collar, hem, cuffs) should be treated with a cleaning agent before washing. This will increase its efficiency and allow you to clean your clothes less often.

- After finishing washing, clothes with synthetic fluff should be fluffed up with your hands, straightened and hung on hangers or a hanger. This way, excess water will quickly drain from it, deforming the material. It is advisable to dry things naturally at room temperature.

- After drying and spinning, it is advisable to rinse the products by hand so that there are no streaks or stains from the powder left on them.

- You can iron clothes at temperatures up to 100 °C.

You can store things with synthetic down in any conditions. They do not lose their shape even after being packed in a vacuum bag.

As the name suggests, this filler is similar in structure to down, and in properties - to synthetic fillers. This is really fluff, that is, a bulky mass, but it consists of artificial fibers. The fibers spring back and intertwine, resulting in a fairly dense structure that provides good thermal insulation.

A warm vest is a contribution to business prosperity

What does a company owner get by ordering promotional clothing for staff? Expenses - yes, but not only. In one action, he solves two issues:

- Forms a positive image of the brand among its customers, because looking at a nice vest, they remember the logo and associate it with a neat and high-quality item;

- Forms a positive attitude of staff towards the brand in general and towards management in particular. An employee in warm clothes feels taken care of and becomes more loyal to the manager, which means he works more actively.

The logo is the head of everything

Promotional clothing without a logo is meaningless. That is why we put the company logo or other image approved by the customer on the vests. The application method depends on the chosen fabric and the project budget.

- Print is a fairly economical option, but the least durable. Will withstand several dozen washes.

- Embroidery is solid and bright. After a few years, even a well-worn vest will delight the eye with the shine of the silky threads with which we will embroider your logo. Lasts for years.

- Thermal transfer and sublimation - durable and strong like embroidery. The only difference is that the image is applied to a special material, and then transferred to the fabric of the product using a thermal method, rather than embroidered on it.

Analogues for replacement in toys

You can replace padding polyester in toys with your own hands. To do this, you can use three main types of fillers.

Natural

It is better to choose cotton wool or wool. These are the most budget-friendly and affordable analogues of padding polyester for toys. However, you need to take into account that the cotton wool filling will lose its shape after washing. The wool cannot be compacted evenly, so the toy will be a little crooked.

Bulk

These fillers are used to increase the weight of the toy. Typically, such products are used for babies, for example, in a rattle toy. As a filler you can use:

- salt;

- seeds;

- cereals;

- husk;

- sand.

Before placing such filler in a toy, it must be sewn into a special bag. It is important to pre-fry the cereals in a frying pan to prevent the breeding of various insects in them.

In addition, such toys cannot be washed. High humidity will be detrimental to them.

Artificial

This is the most practical solution, since these fillers are hypoallergenic and durable. They allow you to give the toy a presentable, voluminous appearance. It is better to use synthetic down, which is soft, airy, and its quantity is required significantly less than synthetic padding.

You can replace padding polyester in toys with your own hands. It will be more difficult to do this in a jacket. For replacement, you can use the options presented in the article. Each has both advantages and disadvantages.