Do you think that padding polyester filler is not suitable for long-term service? Read below why you should choose it and how to determine its quality.

Sintepon as a filler

It is important to know how to care for products with synthetic filler in order to extend their service life. In this article we have collected all types of synthetic fluff and recommendations for caring for it.

Sintepon is often used as a filler for various products. The advantages of the filler are its relatively low cost and practicality. The production of this material is available everywhere.

Let's consider the main characteristics and points that it is advisable to pay attention to when purchasing products with padding polyester filling.

Modern insulation for clothes

In recent years, many new types of insulation for clothing have appeared. Modern technologies make it possible to create very thin, light, but at the same time warm material. Each of them has its own characteristics.

Isosoft

It belongs to the same group of insulation with holofiber, or rather, it is its improved analogue. Isosoft is manufactured using special technology in Belgium. Despite its low weight and density, it retains heat well. In addition, this material does not absorb moisture and allows air to pass through. Absolutely hypoallergenic and often used in the manufacture of children's clothing, including for newborns. Temperature range – up to -25 degrees. Cost – from 4500 rubles per jacket.

Termofin

This insulation is produced in Russia. It consists of a core and a shell in fiber, very porous, so light and warm. Jackets with thermofrin are very soft. In terms of warmth, they exceed the GOST requirements for winter clothing by a factor of two. This filler is often used when sewing workwear, as well as babywearing jackets and jackets for pregnant women. A jacket with 400 g of thermofrin is not cold at a temperature of -50 degrees. The cost of such outerwear starts at 4,000 rubles.

Polyfill

Lightweight, hypoallergenic, warm and soft material. It is often used to insulate classic American Alaskan jackets, as well as clothing for pilots. Polyfill is also used by the popular Canadian brand of children's winter suits, Deux par Deux.

The price for clothes with polyfill is from 12,000 rubles. Temperature range – up to -30 degrees.

Shelter clothing insulation

New from a domestic manufacturer. A distinctive feature of the shelter is the use of silver ions in the manufacture of insulation. Microfibers have excellent air permeability, do not accumulate static electricity, and are flame retardant.

Clothing with a shelter was tested during an expedition to Elbrus. In extreme conditions it retains heat. The material can protect against cold of -50 degrees. It is used to sew clothes for the military, firefighters, security guards, installers, as well as for ordinary city residents. The average price of a jacket with a shelter is 7,000 rubles.

Dupont

Mainly used for insulating men's jackets. Dupont is durable and has excellent heat-saving properties. Although it is positioned as a modern type of insulation, similar material was used back in the 70s for sewing pilot jackets.

Down jackets with dupont are often additionally insulated with camel hair and combined with a membrane top. The price of the products is quite high - from 20,000 rubles. The lowest temperature is -30 degrees.

Thinsulate

The insulation consists of fibers that are 10 times thinner than a human hair. Thanks to this, Thinsulate is very light and can withstand extremely low temperatures (down to -40 degrees). It is often used for sewing workwear for oil workers, astronauts, skiers, and climbers. The wear resistance of Thinsulate is very high. Prices for clothes with it start from 7,000 rubles.

Hollophan

Russian polyfill prototype. The insulation is airy, soft and retains heat well. Sewn on with fabric, repeating the shape of the jacket.

We recommend: Cleaning natural white fur from dirt and yellowness at home

Holofan does not come off when washing and has excellent performance characteristics. Clothes with it are sewn for children, women, men, fishermen, and hunters. Hollophan is also used in the tailoring of luxury clothing from Russian manufacturers.

A jacket with 300 g of filler can be worn in cold temperatures down to -30 degrees. Approximate price – 4000 rubles.

Composition and production

A soft and white material made of thin fibers, similar to cotton wool - this is what padding polyester looks like. It contains thin polyester threads, sometimes with the addition of cotton or wool - they are used to increase the strength and heat resistance of the product.

PVA is often used in production to strengthen the fibers. There are several ways to produce padding polyester, which gives the material certain characteristics. Price differences start from the manufacturing method. Here are the most common:

- Thermal. This method makes it possible to produce a lightweight and durable material by bonding the fibers using high temperatures. The resulting padding polyester protects well from the cold and is not subject to deformation when washed.

- Needle-punched. With the help of metal jagged needles, the fibers are fastened together, forming a lush and soft padding polyester. With this method, the filler is not resistant to deformation.

- Emulsion. A special adhesive composition and synthetic threads are what padding polyester is made from. The material as a result of such processing may cause allergic reactions. It is not resistant to deformation, and with frequent use it quickly rolls off.

Modern silicone insulation

Shelter insulation is a Russian microwave-based polyester insulation that combines the properties of natural and synthetic fibers. This material is distinguished by flexibility and elasticity, airiness and lightness, and high thermal insulation characteristics. It does not shrink after washing and dries quickly, provides comfortable heat transfer and allows the skin to breathe.

Shelter is characterized by uniformity, so it does not bunch up, does not wrinkle and quickly returns to its previous shape. Does not cause allergies, does not emit toxic or harmful substances. Used for the manufacture of bedding, winter, demi-season and sportswear, children's suits and workwear. Suitable for extreme and harsh conditions, but expensive.

Silicone is another new material characterized by high thermal insulation properties, strength and wear resistance, and breathability. It does not get lost and keeps its shape, does not absorb moisture and is easy to care for, withstands repeated washing and use.

It is a light, springy and elastic fiber that allows you to move easily and comfortably. Products with silicone fillers are suitable for active walks and recreation, sports, and do not cause allergies.

Thermofin insulation is also characterized by its light weight, hygiene and hypoallergenicity, high thermal insulation qualities, environmental friendliness and safety. Elastic material allows you to move comfortably. It repels water and does not get wet, retains heat. Used for sewing various types of clothing, including special suits, products for newborns and children, dries quickly and retains its shape.

Main characteristics

- Ease. The weight of the padding polyester product is small.

- Non-absorbency and quick drying. This can be both a plus and a minus when using it.

- Low deformation under normal use. Sintepon holds its shape well and slowly deforms.

- Non-toxic. Synthetic padding polyester created without glue is absolutely safe. Often used for children's products.

- Low melting point. There is a possibility of accidentally melting the “filling” of your favorite pillow. For this reason, it should be kept away from open flames.

Nuances and properties of materials

The prices for this or that insulation are not always justified. If we talk about isosoft, then it is necessary to say that it is produced in Belgium. Consequently, the buyer will have to pay not only the cost of material and tailoring of the product. The final price also includes payment of customs duties and transportation to the destination. If you pay attention to the properties of this insulation, it becomes clear that to achieve a similar effect you can use a triple layer of padding polyester. It will be much cheaper. It is for this reason that isosoft is very difficult to find in post-Soviet countries.

You can often find synthetic winterizer 200 insulation. What temperature is it designed for? At the same time, it is also important to understand that padding polyester is a material that can be connected in different ways. The fibers of this insulation can be connected by adhesive or thermal methods. Both methods are used equally. But if we talk about the thermal method, then under the influence of high temperature the insulation layer becomes a little thinner, the consequence of this is less heat retention when compared with the adhesive bonding method.

So, you have decided to buy a winter jacket using synthetic winterizer 200 insulation. What temperature is it designed for? This material can easily withstand winter frosts down to -10 degrees Celsius. This corresponds to a warm winter.

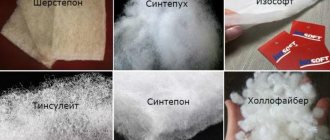

Types of padding polyester

Different types of this material are used for specific purposes. Their main difference is in the additives they add to each other - additives made from natural or synthetic materials.

- Shersepon. Sintepon with the addition of natural wool - used to create products with increased heat resistance. Used in blankets and bedspreads.

- Sinteplast. Non-woven voluminous fabric with the addition of silicone to increase elasticity. Suitable for mattresses, children's rugs and furniture; thanks to silicone, the shape is firmly held and the filler does not roll off.

- Holofiber or padding polyester. Highly crimped fiber with high silicone content on a polyester base. Produced in the form of a sheet or individual balls. Acts as a filler for decorative pillows.

Advantages and disadvantages

Advantages of padding polyester:

- Cheaper than natural materials.

- Elasticity of fibers. Thanks to this, the canvas is less susceptible to deformation.

- Wide variations of application both in creativity and in production.

- Large volume in relation to mass.

Disadvantages of padding polyester:

- When rubbed, it creates static electricity.

- Destruction of fibers due to frequent machine washing and improper drying.

- May cause allergies (created by emulsion method or with the addition of PVA).

Application area

What is padding polyester for the manufacturer? The material is universal, easily accessible and inexpensive, therefore it is used for:

- production of upholstered furniture;

- in outerwear to create an insulating layer;

- filling bedding, soft toys, decorative elements;

- filtration;

- construction work, as insulating material;

Synthetic winterizer with natural additives is used less often. Material with wool threads is used for blankets, pillows and bedspreads. Sintepon with added cotton is suitable for decorative items.

Fabric with silicone is of very high quality, since this additive in the composition makes the product more durable; it is used in mattresses, blankets and expensive furniture.

Sintepon in outerwear

Layers of padding polyester exist in different densities from 60 to 400 g/sq.m. The main difference is in heat conservation. The higher the density of the material, the greater heat efficiency it has

It is important to choose outerwear depending on the temperature at the time of wear. Don't forget that children are more active than adults and their clothes should be thinner.

Synthetic winterizer 100 g/m² is intended for thin coats and jackets for warm autumn with temperature fluctuations up to +5°C. Synthetic winterizer 150 g/m² is well suited for frosts down to -5°C. A coat or down jacket with padding polyester 200 g/m² can be safely worn in late autumn and warm winters down to -10°C. Synthetic winterizer 250 g/m² is suitable for winter -20°C. Material with a density of over 250 g/m² is used in down jackets for frost temperatures of -40°C and above.

When buying outerwear, check the density of padding polyester insulation and calculate based on your individual build. The higher the physical activity, the less you will freeze, so you should take a lower density.

How to understand grams of insulation / underwear and layers of clothing

For young mothers who have not yet delved into all these subtleties about companies, about the amount of insulation and about HOW to dress a child in winter, I decided to write a short review article. Information from the Internet and based on my little experience! Comments and edits are welcome!

Manufacturers usually indicate the amount of insulation on labels/descriptions using numbers or icons (snowflakes). Attention! All children have different frost resistance, so the temperature limits are approximate!

About the insulation:

1. Insulation 80-100 g

(or one snowflake) - demi-season option, designed for temperatures from +15 to +5.

At different times I had waterproof overalls Hippychick, Reima, Lassie for this temperature regime

2. Insulation 160-180 g

(or two snowflakes) - an option for late autumn/warm winter. Designed for temperatures from 0 to -10

If trousers or overalls, then 100-140 degrees is enough for this temperature range.

I had a Reima set for this temperature range: jacket 160 g and pants 140 g.

3. Insulation 200-250 g

(or three snowflakes) - an option for winter frosts. Designed for temperatures from - 10 to - 25

If trousers or overalls, then 150 degrees is enough for this temperature range.

For this temperature regime I had a Pilguni 240 g overalls, Ticket to Heaven 240 g

4. Insulation 300-330 g

- usually chosen for sedentary children (newborns) as a winter option.

For this temperature regime I had a set of Kerry 300 g, Bibon 300 g

About thermal underwear:

When should you wear thermal underwear? — When the overalls/jacket contains a membrane or fabric that has vapor permeability properties.

Child from birth to 1-1.5 years

choose thermal underwear containing at least 50% natural fabrics. Either linen is made from 100% wool or silk-wool, wool+cotton.

Some companies have two-layer options for babies: the top layer is wool, and the inner layer, adjacent to the skin, is cotton (for example, Joha).

Most likely, at temperatures down to -10 degrees, nothing more than thermal underwear and outer overalls will be needed.

Perhaps nothing will be needed even in cold weather - reviews show that when buying merino thermal underwear, mothers save on additional insulation. Plus you need to take into account how many grams of insulation are in your overalls.

Active children (from 1.5-2 years and up to college)

thermal underwear made of polypropylene, polyester and other synthetics mixed with cotton or wool - or pure synthetics - is suitable.

At temperatures below -10 degrees, you may need additional fleece or wool underwear - again, it all depends on the quality of the outer coverall.

If you are buying 100% wool underwear for an older child, be sure to try it on to check the sensations. Many children immediately feel discomfort, despite all the tenderness of products made from merino or llama.

You can read more about brands and types of thermal underwear here

About the underwear:

Poddeva

- This is an intermediate insulated layer put on underwear.

Some call it an undersuit, others an intermediate overall, but the meaning is the same!

The underwear is worn under outerwear over thermal underwear or a T-shirt + tights (for babies on a bodysuit) at an air temperature of -12 -15 degrees.

The main purpose of the underwear

- protection from cold (preservation of heat) and removal of moisture from the body. The better the quality of the material from which it is made, the better the moisture is removed and the less chance that the child will freeze. Thus, it is easier to freeze in a suit made of grandma’s wool, no matter how thick it is, than in a thin modern fleece. In a thick suit, you can sweat and therefore freeze, and fleece will quickly remove moisture without absorbing it.

What to buy as an underwear: Fleece or wool?

For a child under one year old, a woolen overall is preferable; for an older child, again at your own discretion.

In terms of thermal insulation properties, if you compare high-quality fleece and high-quality wool, they are practically the same.

Fleece “works” better for the benefit of the body, it is lighter, more athletic, and a child can wear fleece clothing in cold summers and warm autumns. Plus, fleece is easier to wash and does not require special detergents.

A woolen set will probably be warmer, heavier, hotter. But this does not apply to expensive underwear made of fine wool.

The hem should not be thick!

Warmth is retained due to the special properties of the fabric; thickness has nothing to do with it! When a person moves, he is “warmed” not by thick, but by functional clothing.

Is it possible to wear wool under a membrane?

If your winter membrane kit contains good insulation, you can use wool as an underwear.

In other options (for example, with Reymatek outerwear or other lightweight membrane overalls), it is necessary that the underwear contains at least 15% synthetics. Many factory woolen garments already contain it.

Wool absorbs moisture well, but at the same time continues to retain heat.

A sedentary child (under the age of 1 - 1.5 years) can wear a pure wool underwear for walks at a temperature of -10 with wind or -15 degrees; older children will use wool/synthetics.

What to wear under overalls?

Under a down jumpsuit

or an envelope we put on a knitted sweater - this is the maximum in any frost (the stroller box protects from the wind).

Under overalls on polyester

(Isosoft, etc.) We wear clothes with a mixture of synthetics.

Under the overalls on the membrane

or isosoft, we wear clothes made of non-natural fabrics or wool (conducts moisture to the upper layers of clothing). Any natural underwear or sweaters absorb sweat, causing hypothermia. Ideal option: thermal underwear - at temperatures below -15° we put fleece or acrylic on it.

A very clear example of clothes for a newborn baby for central Russia is here or my example is here

About layers of clothing:

First layer of clothing:

In winter, wearing underwear made from natural cotton is not recommended, since in cold weather cotton quickly absorbs moisture and makes you feel cold. It makes sense to wear underwear made from natural wool - merino or llama. Wool underwear provides excellent warmth while keeping the baby's skin dry, as wool conducts sweat to the next layer of clothing. If the child is very active, it makes sense to use special sportswear made from synthetic fibers.

Second layer of clothing:

The intermediate layer of clothing should be “loose” and voluminous. This could be a sweatshirt and sweatpants with a fleece.

Third layer of clothing:

In severe frost, it is recommended to wear woolen overalls - a cover or a jumper - leggings set.

These products should be made of good “winter” wool (merino or llama).

Finally

In severe frost, you need to use at least three layers of clothing. In light frost, choose the option that is most convenient for your child. Tights and socks in winter should also not be made of natural cotton, since in cold weather such socks become damp quickly and just as quickly get children’s feet cold. It makes sense to wear synthetic tights and “dry body” socks or wool tights and socks with synthetic thermal additives.

Full article here

Caring for products made from padding polyester

When washing clothes with padding polyester, follow the instructions on the tag or in the instructions. If they are not available, we use a temperature regime no higher than 40°C and additional drying in a washing machine so that the synthetic winterizer does not lose its shape. Dry clothes strictly in a horizontal position to avoid redistribution of threads. If the material is made of adhesive synthetic padding, we use only hand washing, otherwise filler. Items filled with thermal and needle-punched synthetic padding can be machine washed.

It is advisable to clean clothes and decorative items no more than once a month, and remove minor stains with wet wipes.

Filler care

Clothes in which holophane is used are washed in conventional washing machines, setting the mode to 40 degrees and the minimum spin speed. Drying should not be done near heat sources; clothes should be straightened and dried in a vertical position.

Products with insulation cannot be soaked, as the material may lose elasticity and its performance characteristics will decrease.

Published September 16, 2013

Like

Winter, as usual, is approaching inexorably quickly, so it's time to think about insulation. This article will be devoted to the insulation materials used for this.

A few words about materials:

- Synthetic winterizer is inferior in quality to all others, it is gradually being replaced by other insulation materials, but it is the cheapest;

- Thinsulate is produced in the USA, it is of high quality, but the price is very high;

- Holofiber is a domestic development, in no way inferior in quality to Thinsulate, but cheaper.

Now let's talk about all three materials in more detail:

Sintepon

Sintepon is a non-woven bulk material consisting of a mixture of polyester fibers bonded by heat treatment or a binder. The main properties of padding polyester are the ability to retain heat, lightness, elasticity, and volume. Three main technologies are used to produce this insulation:

- needle-punched method;

- glue or emulsion method;

- thermal method.

When using thermal technology, the synthetic winterizer turns out to be less fluffy, but its fibers are connected more evenly, due to which it retains temperature better and does not allow moisture to pass through as much. Adhesive technology, on the contrary, provides fluffiness, but because of this, the material does not hold temperature so well and is more susceptible to moisture.

Outerwear, bedding, and other textile products are made from padding polyester; this material is used as a basis for furniture upholstery. It retains elasticity for a long time, does not attract dust, does not cause an allergic reaction, meets fire safety requirements and has a relatively low price.

Adhesive padding polyester has a number of serious disadvantages, including:

- high "caking";

- low environmental friendliness;

- rapid destruction when wet;

- severe deformation during repeated compression;

- low thermal insulation and breathability;

- uneven density;

- high fiber migration.

Synthetic winterizer, made using thermal technology, has average thermal insulation and is environmentally friendly, which makes it more suitable for use than adhesive insulation. However, it has a short service life, is characterized by low recoverability and dimensional stability, and high fiber migration. Its cost, like other types of padding polyester, is relatively low and affordable.

Thinsulate

Thinsulate stands out from many types of insulation with its outstanding heat-protective and ventilating properties; it retains heat well and allows excess moisture to evaporate freely. It does not restrict movement, provides convenience and comfort; even a thin layer of this insulation has high heat-insulating properties. It is also durable, unpretentious, and easy to care for. The Thinsulet has proven itself well in Russian conditions; it is suitable for use even in the most severe frosts.

There are several types of Thinsulate:

- With “Classic” - this type is used for dress and urban clothing and is available in three modifications:

- C - without non-woven padding, attached to or using stitching at intervals of 10-18 cm

- CS - has a one-sided non-woven lining, can be attached without quilting (the maximum panel size in this case is 35x45 cm) or, if we are talking about large panels, needs quilting at intervals of 1-0-25 cm

- CDS - has a double-sided non-woven lining, its stitching pitch is 15 cm, thanks to which the insulation can be used in a freely suspended state or by fixing the edge. When using this variety there are no restrictions on the size of the cut panel.

- Type Z, it is intended for children's, casual and professional outerwear, it is also used to insulate gloves, it is also available in several modifications that differ in density and thickness - P100, P150, P230. Any of the options listed is suitable for quilting using conventional equipment. If you are quilting the product through and through, the quilting step should be set in the range from 11 to 25 cm and carefully ensure that the specified interval is not violated.

- Type TIB, used for sewing sportswear, blankets, bedspreads, blankets, sleeping bags. Compared to other types of Thinsulate, this insulation is more voluminous. It is also produced in several modifications, differing in thickness and density: TIB100, TIB120, TIB200. If you work with it, keep in mind that it is better to quilt it with a double stitch, the step should be about 30 cm. The stitch design depends on the manufacturer. When using TIB type Thinsulate, it is better to use high-quality down-proof fabrics, the recommended density is at least 270 threads.

- Type B - Thinsulate of this type is used to insulate shoes.

- Type FR - Thinsulate, which contains fire-resistant meta-aramid fiber. This type of insulation is used to sew fire-resistant clothing for people whose work involves a high risk of fire.

Holofiber

Holofiber is an insulation material with outstanding characteristics. It is an environmentally friendly material, which is confirmed by international certificates. This is a completely hypoallergenic insulation; it does not cause irritation or discomfort even in newborns. Its fiber has a soft elastic structure, thanks to which the material can breathe and does not allow the body to sweat during prolonged use.

Holofiber does not absorb moisture and odors, has a long service life, does not support combustion, holds and restores its shape well, and has high tensile strength.

One of the most important features of this material is its structure. Holofiber fibers have the shape of a spiral spring, which creates an air cushion that reliably holds its shape and ensures heat retention. To avoid the free movement of fibers inside the fabric and to ensure a smooth surface of the material, holofiber is calendered, that is, processed with rollers at high temperatures.

This material can have a density from 40 to 4,000 g/m2. The optimal density of holofiber for urban winter clothing is 200-300 g/m2.

There are three main brands of this insulation - Soft, Medium and Hard, as well as a number of specialized modifications.

Hollofiber Soft is a soft elastic non-woven fabric that is used mainly in the production of outerwear and travel equipment.

Hollofiber Medium (Volumetric) is an excellent filler for children's toys and an important component for creating children's play complexes.

Both of these varieties are very pleasant to the touch, provide good thermoregulation, allow the skin to breathe, do not force it to sweat, and do not cause itching.

One of the popular varieties is holofiber in the form of balls (holofiber with balls). This is a practical material that guarantees especially long-term use of things, which is confirmed by research results. Although manufacturers set the shelf life of their products within 1.5-2 years, there is evidence of things that were used without loss of quality for 12 years, i.e. 6-8 times longer.

Initially, holofiber balls were developed as a filler for hospital and hotel pillows and blankets, but over time its outstanding performance characteristics were revealed, and the practicality of the new material also turned out to be excellent. Therefore, today bedding with holofiber balls inside can be found not only in hotels and hospitals; they are very light and extremely comfortable. In addition to what was listed above, this type of insulation is used for the production of upholstered furniture, children's play areas, bedding and houses for pets, and a variety of design products.

You can also add to the list of advantages of this material that the products in which it is used are easy to wash, easy to clean, dry quickly after washing (this is explained by the fact that the fibers do not absorb moisture), and do not require complex special care. It is necessary to add to all of the above that holofiber does not support combustion. The pillows made from it were awarded the “Quality Guarantee” mark from Soyuzexpertiza.

Holofiber balls are produced using a fairly simple technology. Each ball is a complex interweaving of twisted high-quality synthetic microsprings. Due to this weave, the dimensional stability and softness of the entire material are ensured; for the same reason, it quickly restores its original shape. Holofiber balls are 100 percent polyester; no adhesives are used.

Hollofiber Hard is a rigid non-woven synthetic fabric that has a wide range of applications. It is extremely effective in heavily loaded elements of upholstered furniture, car interiors, etc. With a high surface density, Holofiber Hard can serve as a reliable substitute for foam rubber. This insulation is also used in the manufacture of mattresses; it can be used as a heat and sound insulating material.

Another type of holofiber is TEK holofiber. This material is used when sewing professional winter workwear, for example, for oil and gas workers. It is also widely used in construction and agriculture.

How to care for different types of insulation?

All of the listed insulation materials - synthetic winterizer, Thinsulate, holofiber - handle storage differently. The attitude towards care for these materials is also different. The structure of holofiber and thinsulate is such that virtually no maintenance is required for these materials. Both insulation materials tolerate machine washing or regular dry cleaning well; they can be stored in vacuum packaging (but only if other materials used in the product allow this).

Sintepon needs more careful care. It is not recommended to use a high speed spin after washing, as the material may tear. Vacuum storage is also undesirable, as it often leads to the synthetic winterizer caking and losing its properties.

Nowadays, holofiber is the leader in terms of the combination of accessibility, practicality, efficiency and environmental friendliness; Thinsulate also has good characteristics, but it is noticeably more expensive. Sintepon, alas, is inferior to these insulation materials, benefiting only in terms of cost.

A little physics.

The best thermal insulator available to humans is air, and the more bound (stationary) air is retained per unit volume of insulation, the better our clothes retain heat. At the same time, it is desirable that the material itself has low density and weight, does not absorb foreign odors and moisture, and is also durable, does not lose shape when washed and worn, and meets strict environmental standards for children's clothing. The cost of insulation and its manufacturability during the production process are very important. Conventionally, all insulation for children's clothing can be divided into two large groups: natural insulation and synthetic.

Natural insulation.

Natural fluff. Currently, this is one of the most common and affordable insulation materials used in the production of children's clothing. It is very light, retains heat well and easily restores its shape after deformation. The down of different birds is used, but, as a rule, goose down is used to make children's clothing. The percentage of down and feather is very important. In a good down jacket it is from 60%/40% to 80%/20%, where the first number is the amount of down. In principle, there is no such thing as 100% fluff; this is nothing more than an advertising ploy. Down fibers are very mobile, which requires the use of special dense outer fabrics and linings for the production of children's clothing, which eliminate the possibility of down “climbing” to the surface. All seams on down clothing also undergo special treatment. It is also necessary to take into account that down is an allergen and an excellent breeding ground for mites, so its antibacterial treatment is very important. Also, one of the main disadvantages of down is its ability to absorb moisture and certain difficulties when washing. True, recently models have appeared on the market in which the down is located between the lining and the outer fabric in a special cover and before washing it can be unfastened and taken out, which significantly reduces the drying time of children's down clothing. When caring for down products, it is very important to carefully read the instructions and follow them strictly. care instructions are as follows: the washing temperature should not exceed 30*C, do not wring out the product, dry at room temperature, and periodically “shake” it so that the fluff does not cake in the corners and then streaks do not appear on the upper fabric. Children's down clothes should not be ironed. For minor stains, down jackets can be washed with washing powder with a soft sponge, hanging the clothes on hangers over the bathtub and rinsing the outside with a stream from the shower. Then the drying time will be significantly reduced. Sheepskin or wool. The advantages of this material include its durability, hypoallergenicity and wear resistance. Wool retains heat well, but at the same time absorbs moisture well and has a lot of weight. slightly hinder the child’s movements, so it is best used for sedentary children from birth to one year. Ideal for making children's envelopes and transformers. It is very good if the woolen lining is removable, this allows you to expand the temperature range for using children's clothing. High-quality wool is absolutely not itchy. One of the best wool insulation is made from the wool of New Zealand Merino sheep because it does not absorb the smell of sweat. Children's clothing with “sheepskin” can be washed at 30*C and dried on hangers at room temperature.

Synthetic insulation.

There are many types of synthetic insulation, but the principle of their operation is absolutely the same. Quality, properties and price can vary significantly, although often the difference between very expensive insulation and insulation with an average price is only in different brands. Powerful advertising campaigns of expensive brands are always paid for by the buyer. The cost of delivery and customs clearance also greatly influences the price. We will begin our review with the simplest and most affordable types. Sintepon. Sintepon is made from polyester fibers. The adhesion of fibers to each other can be carried out in two ways: gluing (an adhesive based on PVA emulsion is used) and thermal bonding. Adhesive padding polyester is not very environmentally friendly due to the use of glue, it quickly deforms and “cakes” under loads and washing, it has a relatively high and uneven density, and, as a result, it is heavy, has low thermal insulation ability and air permeability. The migration of fibers in adhesive padding polyester is very strong. Currently, it is practically not used in the production of children's clothing; it can be found only in the cheapest products. Thermally bonded padding polyester is environmentally friendly and hypoallergenic, but due to the small contact area of the fibers it is relatively short-lived. In addition, with any method of soldering, “cold bridges” are formed from the inside to the outer surface of the clothing. Their thermal conductivity is much greater than that of air. This type of insulation has a high degree of fiber migration, rather low recoverability and dimensional stability. Used in the production of inexpensive children's clothing. Hollowfiber. At its core, it is a patented trademark of one of the similar types of padding polyester, but with extremely high consumer qualities. It has many less-promoted analogues with similar indicators and can already be considered a household name. Raw materials for production, technologies and equipment for such enterprises are supplied by the same companies, of which there are few. The advantages of holofiber include high thermal protection, which is not inferior to the best and most expensive samples, environmental friendliness (the material is safe even for newborns), a high coefficient of recovery and dimensional stability due to the springy structure of the fibers. Accordingly, holofiber has low density and weight. In its production, special thermal bonding of fibers is used plus calendering (compaction of the top layer), additional processing of the fabric at a temperature of 180*C to reduce fiber migration. Holofiber does not absorb moisture at all and breathes well. There are many varieties of holofiber with different thicknesses, but their correct selection is the concern of children's clothing manufacturers, not buyers. Isosoft. (ISOSOFT). This type of insulation is completely similar to holofiber, but much more expensive due to the fact that it is produced in Belgium by LIBELTEX. The price is greatly influenced by the cost of delivery and customs clearance, as well as a massive advertising campaign. Thinsulate. (Thinsulate) Thinsulate is considered one of the best synthetic insulation materials; it practically imitates all the best qualities of natural down, but does not fall off when washed and is absolutely hypoallergenic. It consists of very thin fibers, ten times thinner than a human hair, and therefore has the highest thermal insulation properties and low density and weight. Thinsulate holds its shape perfectly and restores its original volume due to the three-dimensional configuration of the fibers. The main disadvantage of Thinsulate is its very high price.

Caring for synthetic insulation.

Machine washable at 30*C, spin speed no higher than 1000 rpm. Ironing is prohibited.

The most common and stupidest question.

What temperature are these children's clothes designed for? This is the question most often asked by our new customers. The ability of clothing to protect against the cold depends on many factors: the type and thickness of insulation, the type of outer fabric and the cut of the clothing, the strength of the wind, the time spent outdoors, the activity of your child and his or her individual characteristics. Shoes play a very important role, because not a single down jacket will warm a child with frozen feet. It is also important what is worn under a jacket or overalls, what kind of sweater or sweatshirt. Therefore, we can only talk about the average temperature of using the entire garment. Any of the high-quality insulation materials can provide protection from the most severe frosts.

Instead of conclusions.

The most important thing is to understand that different types of high-quality synthetic insulation differ in their properties by no more than 20%, and the main thermal insulator is air. Therefore, all the talk that one layer of “expensive” insulation warms as well as four “others” is nothing more than advertising promises and deception of customers. The thicker the layer of bound air, the warmer the children's clothing. That is why all famous companies produce insulation of different thicknesses for different conditions. It’s just that with thin insulation it’s much easier to make children’s clothes more elegant, and then it takes a long time to prove to the parents of a frozen child that this cannot happen, and all technologies are used from space. Be smart, use your head! Good luck to you!

And my jump is terrible...

- For the smartest and most inquisitive...

- Membrane clothing: truth and myths.

- All about thermal underwear.

- How to choose the right children's clothing?

- What is inside? Types of insulation.