Each of us needs good and sound sleep. And in order to make your vacation pleasant and free of discomfort, it is important to choose high-quality bedding. This means that it should be pleasant to the touch, attractive in appearance and quite durable.

Today the textile market offers the widest range of bed linen. These are mainly products made from cotton fabrics. Today we will understand their quality and determine what is better - calico or satin?

Calico and its features

Let's start the description with the best-selling bedding. Calico is a dense and practical material that is made from thick cotton threads. In the fabric production process, simple plain weave is used. The density of calico can be different, and the higher it is, the stronger and more durable the fabric. High-quality bed linen made from this material should have a value of at least 120 g/m2. m.

A lower density is evidence that the fabric will not last long and may stretch out during washing. In addition, low-quality dyes are often used in the production process of such calico, which is why the material can quickly lose its former brightness.

The value of the fabric depends on the fiber used. The thinner the thread, the denser and better quality the fabric. For the production of bed linen, as a rule, bleached, plain-dyed and printed calico is used.

Satin - the treasure of the East

Breathable fabric that does not electrify perfectly removes excess moisture from the surface of the skin. It has excellent thermal conductivity and hypoallergenic properties, making it suitable even for newborns. Satin is easy to use - you don’t need to iron your clothes after washing.

According to chronicles, already in the 12th century, satin was widely used in the territory of the Chinese Empire, where it was used exclusively for the clothes of clergy. For a long time, European connoisseurs of luxury did not believe that the fabric with a smooth shiny surface was made from ordinary cotton!

To this day, natural cotton with a special weave is used in the production of satin, which ensures ideal smoothness on the front side of the fabric. The silky shine of smooth satin is achieved using special twisted threads, the degree of which determines the intensity of the shine. Also, before being put into production, threads undergo a mercerization process - a special acid-base treatment technology that greatly enhances the strength and elasticity of the threads and their susceptibility to dyes.

Incredible! High quality satin fabric can withstand more than 300 washes, maintaining its original qualities.

Bed linen is made from different types of satin - with printed and printed patterns, from crepe-satin (contains artificial threads), from mako-satin (based on long fibers of Egyptian cotton) and even from 3D-satin, on which a realistic pattern is applied using acid printing technology.

Advantages and disadvantages of calico

Before you find out which is better - calico or satin, it is worth familiarizing yourself with the pros and cons of each material. Calico fabric has a sufficient number of advantages, due to which it is in great demand. The main ones:

- naturalness and environmental friendliness;

- breathability;

- ability to absorb moisture;

- strength;

- long service life (withstands up to 200 washes);

- ability to retain heat, making the fabric excellent for use during cold weather;

- low maintenance (can be washed on any mode);

- ease of ironing;

- low cost.

Disadvantages include a relative tendency to wrinkle, as well as the lack of shine, which many consumers like so much.

Satin

This is a completely natural fabric that effectively allows air to pass through and perfectly absorbs moisture. Resting on a bed covered with such a sheet, you will undoubtedly feel enviable comfort and lightness.

We are talking about a dense material characterized by increased wear resistance. It can easily withstand up to 300 washing cycles without losing its shape, brightness of colors, or enviable tactile characteristics.

The weaving density is 120 threads per square centimeter of surface. The unique technology of the production process ensures the smoothness of the fabric. In addition, it practically does not wrinkle during operation. In terms of softness, it can be compared to natural silk.

The front side has a delightful shine, giving the bedding sets a flawless and sophisticated appearance. The inside is matte and rougher, so the sheet will not slide on the surface of the mattress, and the blanket will not bunch up in the duvet cover.

Satin is fundamentally different from other materials in its weaving technology. Twisted facial threads are woven into every fourth fiber from the wrong side. Thanks to this, an incredibly beautiful appearance is achieved.

The technological production process involves the use of special procedures: mercerization and calendering. The material is treated with sodium hydroxide, which gives it additional wear resistance and shine.

Please note: the gloss will fade slightly with repeated washing, but this will not have any negative effect on the strength properties.

Thanks to its ability to retain heat remarkably well, satin is especially comfortable in the cold season. But on hot summer days, sleeping on it can be associated with some discomfort.

On sale you can find premium sets made from Uzbek cotton. They are characterized by increased softness and an incredibly attractive silky texture, which can not only make sleep truly comfortable and cozy, but also give the bedroom interior additional sophistication and splendor.

Quite a serious cost is the only drawback of this material. But if you decide to make such a purchase, you will receive a truly practical, wear-resistant, durable and elegant item that can delight you with its practicality and elegance for a long time.

Feature of satin

Satin is one of the most beautiful, wear-resistant and body-friendly materials, based on natural cotton fiber. This fabric looks very expensive and presentable. It is for this reason that satin was once called “cotton silk”. However, unlike silk, it costs much less. Thanks to its characteristic shine, satin fabric looks like satin, while retaining heat.

For the production of bed linen, high-quality cotton thread of two types is used. True, sometimes manufacturers use synthetic ones. The denser one forms the base of the fabric, and the thinner (twisted) one is used to create the front side. The result is a dense and rough back side and a smooth, shiny front side. It is precisely because the thread is twisted that the fabric acquires a noble shine. Moreover, the more it is twisted, the more intense the shine.

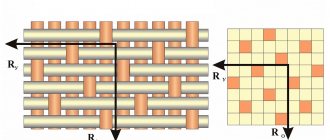

A distinctive feature of satin is that for its production a special satin weaving is used, in which one front twisted thread is intertwined with four back ones. This is what provides the luxurious look of satin fabric. If we compare externally which is better - calico or satin, then the second material wins significantly in this regard.

Satin is a fairly dense fabric. Indicators vary from 80 to 140 g/sq.m. m depending on the variety. It is worth noting that thin material should not be transparent. Satin or calico: which is better for bed linen? The answer largely depends on the quality of the fabric. The higher its density, the longer the laundry will last. Most often, bedding products made of satin are available for sale with values starting from 110 g/m2. m.

In order to give the material more shine, it is mercerized. During this process, satin fabric is treated with alkali, as a result of which it acquires a characteristic silky shine, additional strength and color fastness.

Gloss can also be added by calendering, in which the fabric is rolled between two hot rolls. As a result, the threads become flat, and the satin acquires a noble shine. However, it is worth considering that the gloss obtained by calendering is temporary, and with each subsequent wash it will become less pronounced.

Characteristics of calico

The material is thick cotton fabric. Calico has a plain perpendicular weave “thread through thread”. In its raw form it resembles a paper canvas. It is for this reason that white calico is often called linen.

This material can be produced in several versions:

- plain dyed (uniformly dyed, plain fabric);

- printed (material with a colored pattern);

- bleached (bleached linen);

- unfinished (woven, but not processed fabric).

Calico may contain not only natural, but also synthetic fibers, which improve wear resistance parameters. The manufacturer must indicate the exact composition on the product label.

Advantages of the material:

- low level of creasing (due to density or the presence of synthetic fibers);

- maintaining the bright color of the fabric even after long-term use and repeated washing;

- lightness, hypoallergenic, breathable;

- environmental cleanliness;

- hygiene.

Calico is very practical for everyday use. The fabric can “breathe” and allow air to pass through, which is beneficial for the skin and body during sleep. Fabric is most often dyed using natural dyes that adhere well to the material.

Another useful property is the environmental friendliness of the material. Calico does not lead to allergic reactions, so children's hypoallergenic bedding is often made from it.

Among all the varieties, calico sleeping sets have the most attractive price. This does not mean at all that calico has the lowest wear resistance. Caring for fabric does not require any special conditions or special products. The material rarely tears or wears out.

Benefits of satin

The natural composition of the raw materials used in the production of fabric, as well as the peculiarity of weaving, give satin many positive qualities, such as:

- allows air to pass through;

- absorbs and removes moisture;

- maintains body temperature (creates a feeling of warmth and comfort during the cold season);

- has good wear resistance (satin bed linen can withstand up to 300 washes without losing color and shine);

- does not attract static electricity;

- does not wrinkle;

- pleasant and soft to the touch;

- does not irritate the skin and does not cause allergic reactions;

- does not shrink after washing;

- Due to its smoothness and shine, it looks very presentable, and at the same time it costs much less than silk.

If we compare which linen is better - calico or satin, then taking into account the above advantages, the first fabric is inferior in some respects.

Satin and calico: similarities and differences

First, let's look at the characteristics of each fabric.

For clarity, we present the comparison in the table.

| Peculiarities | Calico | Satin |

| Quality | • shilya – ordinary; • hanagai - high | • simple – ordinary; • mako-satin – high |

| Coloring | • woven, but not dyed; • bleached (bleached); • plain-colored (plain color, evenly colored); • printed (with color pattern) | • bleached; • plain-colored; • printed |

| Compound | • cotton; • cotton + minor synthetic admixtures | • cotton; • cotton + artificial fibers; • cotton + natural silk threads |

| Density (g/sq.m) | 110-160 | 115-140 |

| Weave type | simple (linen) | complex (satin) |

| Surface | matte | double-sided: • front side – smooth, silky, with a slight shine; • reverse side – matte, slightly rough to the touch |

| Strength | high | |

| Varieties | • light (light); • comfort; • luxury; • ranfors; • standard | • regular (cotton); • silk-satin (silk threads added); • jacquard-satin (with a woven pattern, both sides are facing) • mako-satin – made only from high-quality, highly twisted, finest threads of long-staple Egyptian cotton, without synthetic impurities. Bed linen sets (BCS) made from it have the highest quality parameters and belong to the premium class. |

| Life time | long lasting without deterioration of properties | up to 300 washes without loss of properties and appearance |

| Application area | • for sewing children's and summer ladies' dresses; • for sewing bedding sets, including for children and newborns | • for sewing women's and children's dresses; • men's shirts; • for sewing bedding sets |

| Care | does not require special care | |

| Wrinkleability | high, easily forms creases and folds | practically absent, with slight shaking it takes on a neat appearance |

| Price | inexpensive | more expensive than calico, cheaper than silk |

Disadvantages of satin

There are practically no downsides to satin lingerie. However, some users who prefer to sleep in silk pajamas note that, due to the slipperiness, sleeping in expensive underwear on such a bed is not entirely comfortable. Also, consumers sometimes complain that satin bedding is not entirely suitable for use in the summer, since it is quite hot to sleep under it.

How to care for satin linen?

There are several recommendations regarding the steam care of satin linen, which will help preserve the attractive appearance of the material for a long time:

- The first and all subsequent washes are carried out at a temperature not exceeding 40 degrees. It is advisable to use the “cotton” mode.

- Before placing fabric items in the washing machine, you need to turn the items inside out and straighten the seams.

Additional Information! It is not advisable to fill the drum too much so that the fabric is washed well and the powder is rinsed out thoroughly.

- Before hanging laundry to dry, you need to thoroughly shake each item - this will minimize the degree of wrinkling.

- You can iron the fabric at a maximum iron temperature of 90 degrees.

You might be interested in this All about ribana, description of fabric with lycra and comparison with cashhorse

Seeing the weave

Note! When performing any procedure - ironing, washing, it is recommended to turn the products inside out so that the color palette is preserved longer and the seams are cleaned.

Bed linen: satin or calico - which is better?

Today, both calico and satin are popular. Both materials are ideal for sewing bed linen. Of course, satin is considered to be of higher quality. It is stronger and more durable in use. Satin, due to the peculiarities of weaving the fabric, looks more attractive than calico. In addition, according to numerous reviews, bed linen made from this material does not lose its bright color for a long time and is very pleasant to the body.

For this reason, when wondering which bed linen is better - calico or satin, know that in terms of performance and external qualities, satin clearly wins. As for the price, the opposite is true. Calico sets are more affordable. Therefore, it is impossible to answer unequivocally what is better - calico or satin.

When choosing bedding, you should rely on your own taste. Even though satin has more benefits, some consumers say they prefer sleeping on a calico bed. Therefore, choose the option that you like and can afford.

How to choose satin underwear

To make the right choice of bed linen, you should pay attention to the following details:

- Pay attention to the composition of the fabric. Only cotton should be present.

- The optimal density should be 120 threads per 1 cm². Density may be indicated in grams.

- It is advisable to choose fabric with mercerization. This treatment makes the color more resistant to fading.

- The sheet, duvet cover and pillowcases should be as smooth as possible; if there are roughnesses on the surface, the fabric will quickly roll up.

You might be interested in what sequins are and their varieties

Bed linen is often used in classic interiors

The remaining features of the choice are standard when purchasing bed linen - selecting the preferred color and size, checking the quality of the seams.

Production

Butterflies

Today, satin is supplied by a large number of companies whose production facilities are located in the following countries:

- Türkiye;

- Russia;

- China;

- Pakistan;

- Italy.

Despite such geographical dispersion, production technologies are almost identical everywhere, with the exception of some minor features.

Mercerized cotton is used as the main raw material. This process is named after John Mercer, who first used it.

Mercerization involves soaking cotton alternately in an alkaline solution and in an acid. As a result, the raw material becomes more durable and easier to paint.

After this, the fabric itself is woven from the threads, while twisted threads are used for the front side, and the more they are twisted, the more shiny the material will be.

Next, the fabric is bleached and dyed, which can be done in one of two ways:

- Pigment - the dye is applied to the front side. This method is typical for inexpensive types of satin.

- Reactive dyeing is a more complex and expensive method in which the dyes are absorbed into the fibers and do not fade, wash off or wear off over several hundred washes.

Bed sheets

One of the areas of application of the finished material is the production of bed linen. Typically, a type of fabric such as mako-satin is used for this.

The threads of this fabric are very thin, but strong, and the linen turns out to be very delicate and at the same time wear-resistant and durable.

Often cheaper types of satin are used for bed linen, which instead of mercerization are only calendered. This is a process in which cotton is simply rolled between heated rollers of special machines - calenders.

This type of underwear is also quite dense and can last no less than its expensive counterparts. The only disadvantage of such products is that the design begins to fade after several washes , and the shine of the fabric disappears.

Dresses

Dress made of silk crepe satin

similar to expensive silk clothes, are very popular . For such products, only mercerized cotton is used.

But satin is not used for all types of dresses, and its rich, bewitching shine is a powerful argument for sewing such aristocratic models from satin as:

- Sheath dress , which will never go out of fashion among regulars of social events and banquets;

- Floor-length skirts and their flared varieties;

- Chic evening dresses and prom .

Satin dresses do not require special care, the only important requirements relate to washing.

It is better to wash such material by hand and separately from other things in water at 40 degrees. It is not recommended to wring out the dress, and ironing can only be done from the inside out.

Definition

Satin is a very dense cotton fabric made from double weave threads. This method of twisting the thread makes the surface of the finished fabric smooth and shiny, like satin. This is how “satin” is translated from French. The method of its production was brought to Russia at the end of the 19th century, but the fabric itself was used long before the first meter of domestic satin was produced.

Satin

Calico is a natural cotton fabric of plain weave, in which a thick, strong thread is used as the warp, and thinner threads made of cotton or synthetic material are used for the weft. This method of weaving makes the surface of the fabric durable and double-sided, and the fabric itself is light and pleasant to the touch, despite the high density and not always high content of natural fibers.

Calico

Satin weaving technology

Satin, calico and poplin are fabrics that are made by twisting two types of threads. Only satin weaving is more complex than representatives of the other two types. Cotton is used as the main material, but silk, synthetics and other fibers can be woven into the fabric. This will be reflected in the appearance and technical characteristics of the fabric. A dense thread is used for the warp. A thinner thread is twisted and woven into the warp, which adds shine to the front. The stronger the curl, the greater the shine.

The Great Silk Road

To improve the appearance of the fabric, additional treatments are possible:

- Marcerization. The fabric is treated with sodium hydroxide. The result is additional shine and strength. Colors become more durable.

- Calendering. Heated calender rolls are used. The fabric is rolled between them, smoothed out and becomes even more shiny and smooth. It is worth considering that this shine will decrease with each wash.

You might be interested in the main distinctive characteristics of nubuck and suede

Weaving

Note! The back of the fabric is always matte. Only the front side shines.

Finally, the canvas is painted. Patterns and colors can be varied. Thanks to its characteristics, the material retains the brightness of color and pattern for up to 300 washes.

Color variety

When applying a printed pattern to a canvas, pre-dyed fibers are used. 3-D drawing is popular. This bedding looks very unusual and beautiful.

Bedding with 3-D pattern

What is the difference between calico and satin?

At first glance, it may seem that satin and calico are very similar in their properties. This is due to the almost identical composition. But there is a difference, and it is explained by the peculiarities of weaving.

- Price. Although both fabrics are made from cotton, satin is much more expensive than calico. This is because of its resemblance to silk. For example, a one-and-a-half sleeping set made of calico with a pattern costs about nine hundred rubles. Satin underwear with similar parameters will cost one thousand six hundred rubles. Satin also looks more expensive. But if appearance is not that important to you or you simply don’t like the shine of this material, then you should choose calico.

- Comfort. Due to the smooth sliding surface of satin, sleeping on it is much more pleasant. Although this criterion is quite subjective.

- Durability. According to this indicator, satin takes the lead. Yes, both materials are very durable. But calico begins to lose its quality after fewer washes.

Description and types of calico

This fabric has been known in Russia for many centuries. It has long been brought to our lands from Asian countries. Even then, this material was distinguished by its cheapness and variety of types, so the fabric was used both for sewing casual clothing for women and children, and for the production of army underwear.

Calico is not the fibers themselves. This is the name for a material with a special way of weaving threads - crosswise. Because of this, the fabric pattern is the same on both the front and back sides.

But the composition of calico may differ. According to the standards established in Russia, it must consist entirely of cotton. But not everyone follows these rules, and in our stores there is a lot of bed linen supplied from other countries. So it’s difficult to find completely natural calico. The maximum amount of synthetic material that is allowed in good calico is fifteen percent.

There are four main types of this canvas:

- harsh calico - usually used for upholstery;

- bleached - this is what is most often used for bed linen;

- printed - such calico attracts attention with its bright colors and patterns; it is often used to make home clothes, but it is also suitable for sleeping sets;

- plain-colored - one-color variety.