Types of textiles by fiber type

The characteristics of the fabric directly depend on what threads it is made from. According to the production method and chemical composition, all textile fibers can be classified into three groups:

- Natural.

- Artificial.

- Synthetic.

Natural or natural threads are of plant origin: flax, cotton, or animal origin: wool, silk. Their main advantage is environmental friendliness and safety for human health.

Artificial ones are obtained through chemical transformations from natural components. Most often, cellulose from different types of wood is used as raw material. The most common artificial fabrics are viscose, bamboo, acetate, and modal.

Such fabrics are distinguished by their attractive shiny surface, high degree of aeration and hygroscopicity. Their disadvantage is their low strength, especially when wet.

The starting materials for synthetic fibers are products from the processing of coal, oil or natural gas. The fabrics that are obtained from them - lavsan, acrylic, polyester, nylon, elastane and others - have increased strength and abrasion resistance. But unlike representatives of the other two groups, they do not have good breathability and do not always meet hygienic requirements. In some cases, synthetics can even provoke an exacerbation of diseases in a person - allergies or asthma.

Taking into account all the positive and negative aspects of each type of fiber, manufacturers produce blended or combined fabrics with optimal characteristics, which include both natural and chemical components.

Physical (hygienic) properties of fabrics

This group includes hygroscopicity, air permeability, vapor permeability, water resistance, water resistance, wetness, thermal conductivity, dust holding capacity, electrification, etc.

Hygroscopicity. The ability of fabric to absorb water vapor from the surrounding atmosphere. This indicator is not constant for the same product. It is designed to change as relative air humidity and temperature change. So, for example, moisture absorption by clothing indoors will be less than outdoors. Clothing that comes into contact with the body should have good hygroscopicity, while for the outer layers of winter and demi-season clothing it should be minimal in order to prevent getting wet and reducing the heat-protective properties.

Wetness. This is the ability of fabric to absorb droplet moisture. This property comes to the fore in linen, towels, sheets and other fabrics.

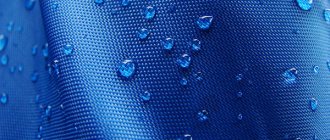

Water resistance. The ability of materials to resist wetting. To do this, their surface is treated with a special compound. At the same time, the pores of the fabric are not filled, which allows it to “breathe”. It is important to know that water resistance and water resistance are not the same thing.

Waterproof. The ability of a fabric to resist both wetting and water penetration. But when processing fabric, the pores are also filled with a special composition, which significantly worsens the hygienic properties, because air permeability and vapor permeability are reduced to almost zero. However, this characteristic is very important for raincoat and coat fabrics.

Breathability. The ability of fabric to allow air to pass through, thereby ensuring ventilation of clothing and creating a comfortable humidity composition of the underwear space. It is known that carbon dioxide can accumulate in a higher concentration in the under-clothes space than in the air space. This can lead to fatigue in a person, as well as a fainting state. Low-density fabrics have the best breathability characteristics. The surface layer of winter and autumn clothing should have low breathability in order to protect against cold air. Summer clothing should have good ventilation.

Vapor permeability. The ability of fabric to remove water vapor released by the human body into the underwear space. This is a very important characteristic for lining, linen, dress, blouse and suit fabrics. Thus, wool evaporates water vapor the slowest and, thus, has the best heat-protective properties. But the coolest linen fabric evaporates water vapor the fastest and is ideal for hot summers.

Thermal conductivity. Characterizes the heat-shielding properties of materials: the lower the thermal conductivity, the warmer the material. First of all, the heat-shielding properties of a material are affected by its thickness. The pores of thick material contain more air, which has low thermal conductivity. Therefore, the thicker the material, the warmer it is.

Dust capacity. This is a negative property of fabric, characterized by its ability to absorb dust and various contaminants from the environment. Brushed fabrics, especially wool, collect the most dust.

Electrification. The ability of fabric to accumulate static electricity on its surface. As a result of friction, positive or negative charges are formed on the surface of the fabric. Negative charges, especially characteristic of synthetic fabrics, can have a negative effect on the human body.

Classification of textile properties

Textile materials include three types of fabrics: woven - obtained by interlacing threads on special machines; knitted, which are produced by knitting; non-woven - made by other methods, such as felting. All of them, regardless of origin, are characterized by certain properties, which can be classified as follows:

- physical and mechanical;

- hygienic;

- geometric;

- technological;

- operational.

Let's consider the qualities of fabrics that are included in each of the listed groups.

Physical and mechanical

These are factors that characterize the ability of textiles to withstand serious loads - compression, bending, friction, etc. This group includes the following indicators:

- tensile strength. Depends on the composition of the material, the thickness of the threads, the method and density of their weaving. Synthetic fibers have the greatest strength, cotton and wool have the least strength;

- creasing. This is the ability of fabrics to form folds, creases and wrinkles, which can only be eliminated by ironing or steaming. Cotton materials are considered the most easily wrinkled - chintz, calico, staple, and polyester fabrics are the least susceptible to deformation;

- drapeability. Some fabrics - silk, viscose, satin, chiffon and others - are very soft and pliable. They easily form beautiful folds, adding special attractiveness and elegance to the products. Denser and stiffer fabrics - velvet, jacquard, moleskine - drape poorly because they do not have the necessary flexibility;

- rigidity. This property refers to the ability of tissues to resist changes in shape. There are materials that stretch and sag over time. Others, on the contrary, retain their original appearance for several years;

- wear resistance. During operation, under the influence of mechanical, biological, chemical and other factors, fabrics lose their original appearance and are destroyed. The fibers become thinner, fall out, the material stretches and becomes unusable. The highest level of this indicator is found in synthetic fabrics and materials with satin or satin weaves. Cotton fabrics with a simple linen method of joining threads wear out first.

It is important to know! Very often, rapid wear of products is caused by their incorrect operation and neglect of maintenance rules. Washing at unacceptable temperatures, ironing synthetic items with a hot iron, strong spinning or drying on heating devices can dramatically reduce the service life of even the most resistant fabrics.

Hygienic

The fabric not only protects people from exposure to dust, dirt, bacteria and microorganisms. It itself must be completely safe: not emit harmful substances and not provoke the development of various diseases. Hygienic indicators include:

- hygroscopicity. This is the ability of fabrics to absorb atmospheric moisture and retain it under certain conditions. The indicator is not a constant value and varies depending on the air temperature and its humidity. If the room with closed windows is drier than outside, then the level of hygroscopicity will be lower. This value is highest for natural materials, for example, knitted fabrics and interlock. Synthetic and artificial fabrics are significantly inferior;

- wetness. Essential characteristics of towels, linen, outerwear, etc. To determine the level of water absorption, place a sample of the material in a container of water for one minute. Low wetting for raincoat fabrics, diagonals, fabrics with twill weave;

- breathability. There is air between the body and the inner layer of clothing. Through pores in the material, it is exchanged with the outside. When this property of a fabric is weakly expressed, a person begins to steam in clothes and sweat heavily, which negatively affects his comfort and is harmful to his health. It is especially important that the material “breathes” in children's clothing. The highest breathability is found in fabrics made from natural raw materials;

- thermal protection. This property preserves the heat generated by the human body. This is especially true for clothing intended to be worn in the cold season. Heat saving directly depends on the amount of air that accumulates in the fibers of the material and between them. Woolen fabrics are recognized as the warmest, as well as recently introduced synthetic fillers - Thinsulate, holofiber and isosoft;

- dust capacity. An indicator that is considered negative, since the active accumulation of dust and dirt in the pores of the material leads to the loss of not only its appearance, but also its functional properties;

- electrification. Many synthetic fabrics can create static electricity on the surface. Most often this occurs when products come into contact with human skin or when two fabrics rub against each other. Discharges occur so strong that sparks are formed, especially noticeable in a dark room. This property is also a disadvantage, and textile manufacturers are trying to get rid of it.

It is important to know! Doctors believe that the increased electrification of clothing and home textiles has a negative effect on the human cardiovascular and nervous system. To protect yourself from this unpleasant phenomenon, products must be treated with antistatic aerosols before wearing.

Technological

The technological qualities of fabrics are determined during cutting or sewing. These include the following characteristics:

- cutability. This is the ability of a material to be damaged by a needle. Such places are called holes; they significantly reduce the strength of the canvas and violate its integrity. The lowest indicators are found in loose fluffy fabrics with large gaps between the fibers. The needle easily gets between the threads and does not tear them. In contrast, this property is clearly expressed in materials with increased density, as well as those containing viscose or acetate. Cutting is especially dangerous for knitted fabrics, on which arrows and hooks can form. Therefore, needles and threads should be carefully selected for each fabric, and the appropriate stitch size should be set;

- crumbling. Materials with satin or satin weave suffer from this phenomenon. Both during work and during wear, individual threads may fall out of the cuts and seams, forming a fringe. Flowability is dealt with by applying special strengthening compounds to the fabric. Some canvases are pressed or rolled;

- slip. And again, as in the previous case, satin and satin come out on top. These beautiful shiny and smooth fabrics literally slide off the cutting table or under the sewing machine. Many silk and viscose materials also have high slip properties. When working with them, you need to use a backing made of flannel or felt;

- opening of seams. It is believed that the greater the difference between the thickness of the warp and weft threads, the greater the likelihood that the material will begin to “crawl” at the seams. This especially applies to problem areas - darts, sides, armholes, fasteners, etc. This not only worsens the appearance of things, but also significantly reduces their service life. To eliminate the shortcoming, the stitching is made more frequent;

- picturesqueness. The degree of complexity of a pattern or pattern can significantly increase the fabric consumption when cutting. The simplest are small cells, flowers or circles. Difficult-to-design materials include jacquards, tapestries and other materials with intricate interweaving of lines;

- fabric cutting resistance. This property depends on the thickness, density and rigidity of the material, as well as on whether it has been pre-impregnated with various compounds. Linen and some cotton fabrics are very difficult to cut; the most pliable are silk and wool.

It is important to know! Before purchasing, it is advisable to familiarize yourself with the sewing properties of the fabric. Considering the difficulties that may arise when cutting and stitching on a machine, you need to select problematic materials with a reserve.

Operational

These include characteristics that have a direct impact on the service life of products. Under the influence of various factors, the material may lose its attractiveness or become completely unusable.

- Shrinkage. Many fabrics shrink after soaking, washing or steaming - changing their original geometric parameters. At sewing enterprises, this leads to unnecessary costs: craftsmen are forced to increase the size of the patterns and spend more material. Synthetic fabrics give the minimum shrinkage, and natural fabrics, especially cotton and wool, give the maximum. In order to reduce this deficiency, fabrics are pre-treated using special anti-shrink machines or decatification is used - forced soaking.

- Form stability. This property is also called the plasticity of the material. When sewing, sometimes it is necessary to forcibly reduce a certain section of the fabric using wet-heat treatment or, on the contrary, stretch it. Some materials are easy to mold. These include loose cloth pure wool. Materials that have a pile or a convex pattern most often cannot be ironed and are considered non-plastic.

- Elasticity. This property is most pronounced in lycra, a synthetic polyester material. Cotton and linen have the lowest elongation. In order for clothes to fit the figure well, a small amount of lycra is introduced into many fabrics.

- Peeling. It happens that after prolonged use, small pellets appear on the surface. The susceptibility of the fabric to peeling is determined by testing it on special machines. If after 400 cycles no lumps appear, the fabric is considered anti-pilling. These materials include many types of synthetics, for example, microfiber.

- Light weather. Quite often, the cause of premature wear of textiles is the impact of certain atmospheric factors - sunlight, high humidity, temperature, oxygen content - causing photochemical processes. Natural silk and synthetic nylon are the least resistant to light weather, while wool, nitron and polyester are the most resistant.

It is important to know! Clothes made from fabrics that can deteriorate when exposed to ultraviolet rays should be hung in a darkened room after washing. This will significantly increase its service life and maintain its attractiveness for a long time.

Geometric

These characteristics determine the basic dimensions and weight of textiles. The list of indicators includes:

- fabric length. It is measured in the direction of the warp threads. This figure can vary from 10 to 150 m. It should be taken into account that when laying sheets for cutting, their length can increase due to their tendency to stretch;

- width – the distance between the edges of the material. Linen fabrics have a width of 0.6–1 m, dress fabrics – 0.9–1.1 m, and coat fabrics – 1.3–1.5 m. It is very important to correctly apply patterns to the material during the cutting process in order to reduce losses;

- thickness. This indicator is measured between the most protruding fibers of the front and back sides. For cloth and drape it is 3–3.5 mm, and for chiffon or organza it is 0.15–0.2 mm;

- the mass of the fabric depends on its surface density, which ranges from 10 to 750 g/m2. For each article, this indicator is strictly fixed, and deviation from it is considered a violation of quality standards. To determine the surface density, a sample of the fabric is measured and weighed in laboratories, using only special verified instruments.

In addition to the above properties, the way the fabric looks is also important. When purchasing, you should pay attention to very significant aesthetic indicators: surface texture, color, brightness of the fabric, shine, the presence of decorative elements, for example, metallized lurex threads.

It is important to know! The manufacturer attaches a label to each roll of fabric that lists geometric parameters, fiber composition as a percentage, degree of color fastness and crease resistance group. In order not to make a mistake with your choice, you should carefully read the description of all the characteristics of the material.

In order to best satisfy customer requirements, fabrics must have a complex of different properties. After familiarizing yourself with them, you can purchase a material that is ideal for a particular product.

Textile materials and their properties

Textile materials

surround us everywhere.

Table linen is made from these:

tablecloths, napkins, towels.

Bed sheets:

pillowcases, sheets, duvet covers.

They are used to make curtains, upholstery, carpets... And most importantly, our clothes are made from textile materials.

In order to sew any product you need fabric

.

Any textile materials exhibit certain properties under different conditions.

They must be taken into account when choosing and manufacturing garments, when processing and caring for clothing

.

The properties of fabrics are varied and depend on the properties of the fibers from which they are made, the type of weave and finishing features.

All properties of fabrics can be divided into several groups:

physical, ergonomic, aesthetic and technological.

Physical properties

characterize the ability of textile materials not to wear out for a long time and maintain their appearance.

Physical properties include:

· Strength

- This is the ability of a fabric to resist tearing. Similar loads are experienced by fabrics in clothing in places that fit human joints: elbows, knees, shoulders.

· Wear resistance

–

this is the ability of a material to withstand the effects of friction, torsion, light, moisture, temperature, microorganisms, moths.

Shrinkage resistance

.

Shrinkage is the reduction in the size of products during washing processes and other moisture-thermal influences.

For example, reducing the length of trousers after washing in hot water. · Resistance to creasing

. The creaseability of textile materials refers to their ability to form, when bent and compressed, permanent folds and wrinkles. The ability of a material to restore its original shape (smooth out) after bending and compression is called crease resistance. The wrinkleability of the fabric depends on the elasticity of the fibers.

· Resistance to pilling (pilling) and shine (lasing)

.

The ability of fabric to roll up (form pellets) during use is called pillability in the language of professionals.

Pillability is affected by fiber composition, thread structure, fabric structure and finishing. Ironing or pressing fabrics under increased pressure causes the threads to flatten, which makes the surface of the fabric very smooth. As a result, increased shine (lases) appears on the fabric. Ergonomic properties

characterize how harmless the material is to humans.

· Hygroscopicity

is the ability of textile materials to absorb moisture and release it into the environment. For example, underwear should absorb sweat well. But outerwear is to protect the body from getting wet in the rain and snow. This property is also especially important for linen.

· Breathability

- This is the ability of textile materials to allow air to pass through. All natural fabrics are able to “breathe”. This property is important for clothing. For example, winter clothes should protect from cold air, and summer clothes should allow air to pass through well so that it does not get hot.

· Water resistance

- This is the ability of textile materials not to allow water to pass through. This property is especially important for raincoats, umbrellas, and tourist tents.

· Thermal protection

– the ability of fabric to retain the heat of the human body. Natural fabrics give us their warmth and energy. The greater the thermal insulation of the fabric, the warmer the clothing. This property is very important for winter clothing.

Aesthetic properties of textile materials

- these are properties that characterize the beauty of fabrics and products made from them and characterize a pleasant appearance.

These include:

· Artistic and color design

, that is, the pattern and color of the material.

The pattern of fabrics is obtained during the weaving process, using appropriate weaves, as well as during the finishing process. The color of the material has an emotional and psychological effect.

For example, red, orange and yellow colors, called warm colors, attract attention, enliven clothes, and sharply reveal all the features of a person’s figure. But blue-blue (cold) colors calm, hide individual imperfections of the figure, make it thinner, slimmer, etc.

· Texture

– this is the expressiveness of the surface. That is, they distinguish between smooth, even, rough, patterned-smooth, embossed, and pile fabrics. The texture of the fabric is of great importance in the visual perception of the product. For example, rough and embossed textures of fabrics increase the volume of the product and make it heavier. A smooth texture, on the contrary, gives clothes lightness and visually reduces their volume.

· Drapability

- this is the ability of fabric to create a beautiful shape in the form of soft folds. The softer the fabric, the higher its drape.

Technological properties

characterize how convenient it is to work with this material, cut it and sew it.

These include:

Fabric frayability (flowability)

- this is the ability of threads not to be retained in the fabric along the cuts, to slip out and crumble, forming a fringe. High shedding of threads makes it difficult to process the product. Therefore, the sections of the cut parts must be sewn immediately.

Fabric slip

- this is the mobility of one layer of tissue relative to another. It is difficult to work with such fabric when cutting, basting and stitching parts, so you have to use pins with heads to cleave and secure the fabric. Slip depends on the smoothness of the fabric and the type of weave.

The listed properties manifest themselves in different ways in textile products.

This depends, first of all, on what raw materials they are made from, that is, on the composition of the fiber.

Natural fabrics are of plant and animal origin

. Fabrics of plant origin include fabrics obtained from fibers of various plants. The most commonly used plants are cotton and flax.

Fabric made from cotton is called cotton.

Cotton fabrics

slightly rough and lacking shine, their threads are the same thickness everywhere.

The threads do not fray when cut, so it is easy for beginner seamstresses to work with cotton. Cotton dyes well and hardly fades. Cotton is quite durable

Absorbs moisture well without becoming damp to the touch.

But it allows air to pass through worse than linen. It gets dirty quickly, but washes very well. Cotton fabric

can shrink a lot when washed and takes a long time to dry.

Currently, there are many types of cotton fabrics.

Chintz

- This is a lightweight plain weave fabric. It is used for sewing summer dresses, sundresses, bathrobes, children's clothing, bed linen and baby diapers.

Batiste

- This is a translucent thin and soft fabric of plain weave. It is used in sewing blouses, summer dresses, and various lingerie.

Flannel

- This is a soft fabric with double-sided brushing. It is used for sewing winter children's products, warm men's shirts, dressing gowns, pajamas and diapers.

Denim

- This is a very durable and dense cotton fabric with twill weave. It is used in sewing trousers, skirts, suits, shoes, bags, hats, and is also used in the manufacture of shoes. Denim is very popular nowadays.

Velveteen

- fabric with a pile in the form of longitudinal scars. Used for sewing outerwear, coats, suits, skirts, trousers.

Linen fabric.

This is a fabric that is made from the fibers of a plant called

“flax”.

Linen fabric

moisture- and air-permeable, heat-conducting, does not get dirty and washes well, has a pleasant shine, and does not cause allergies. Summer clothes are made from flax, which, thanks to the properties of the fabric, are pleasant to the body in hot weather, the body breathes in it. The clothes are wear-resistant, but wrinkle very much and can shrink a lot if washed incorrectly.

Currently, there are many types of linen fabrics.

Linen cambric

- This is the finest translucent linen fabric. Used for sewing women's underwear and light clothing.

Canvas -

This is linen fabric made from thick yarn. Currently, canvas is used for sewing outerwear, shoes, workwear and work gloves.

Canvas –

This is a coarse and dense plain weave fabric. Used for sewing workwear, tents, awnings.

Textiles made from plant fibers last a long time and are very pleasant to the body:

they are durable, hygroscopic, breathable. They wrinkle easily, but smooth out well. When washed in hot water they shrink. When burned, they emit a burnt paper smell and leave gray ash.

To make garments, in addition to fabric, you need many additional materials.

Sewing threads

are the main material for connecting clothing parts.

In addition, they also serve as a finishing material. They vary in composition and thickness; they are chosen depending on the thickness of the fabric: thin fabrics are sewn with thin threads and vice versa. Basic Requirement

– threads must be durable, high quality and match the color of the fabric.

Decorative braid and ribbons are used to decorate products.

Braid

- This is a narrow strip with diagonal threads.

It comes in various widths and colors, stretches well (widthwise), and is easy to handle corners and curves. Braid

It can be woven or knitted. To ensure that the skirt or trousers fit snugly at the waist, an elastic band (elastic band) is inserted into the hem.

Ribbons

made on ribbon looms of various weaves.

According to their purpose, tapes are divided

into decorative and finishing, clothing and auxiliary, applied and special purpose.

Lesson summary.

We learned about textile materials. We found out what properties they have. We looked at the types of fabrics and their applications.