History of appearance

The satin material owes its appearance to the Chinese. It was from distant China that in the 12th century, Arab merchants began to export specially woven fabric, made at that time from expensive silk. It is the technology of weaving threads that is called “satin”. The surface had a special gloss. It was incredibly expensive. Festive ritual clothes were sewn from it. The price was so high that only very wealthy people could afford such luxury.

Amazing satin fabric

In the mid-19th century, Europeans began producing the material using new technology, using cotton threads. New products have become accessible to the middle class. It is used for sewing festive dresses and lingerie. The most popular direction is bedding sets. What else can be made from satin - home textiles, tablecloths, curtains, draperies and much more.

Variety of fabrics

History of creation

Satin appeared in the Middle Kingdom 800 years ago. It appealed to the Arabs, who bought the material in the Chinese port of Quanzhou. Arab sailors called this port “zaytun”. The name of the fabric comes from this word.

In the 12th century, when satin was invented, only wealthy people wore it. Expensive, magnificent ceremonial clothes were sewn from the material. For ordinary Chinese it was a luxury. However, Europeans, primarily wealthy aristocrats, became interested in satin fabric. Export to Europe began already at the end of the 12th century. And the Europeans themselves began to make satin only in the 19th century - in 1850, John Mercer patented a method for its production. However, noble fabric remained the privilege of the rich for quite a long time. Fashionable outfits for special occasions were made from satin, which were quite expensive, and lingerie was made for noble ladies. Only at the beginning of the 20th century could all segments of the population already afford the material, and then its mass production began.

Many centuries after its invention, the popularity of satin remains. It is used to make clothes, bedding, and upholstery furniture. Even after 800 years, Chinese material still delights the eye with its exquisite shine.

Material composition, properties

Initially, the fabric was made from silk, but since the development of the subsequently patented satin technology, the composition of the fabric was changed and began to be made from cotton fiber. Threads can be natural, without the addition of synthetics, or using synthetic materials.

The properties of a fabric are determined by its qualitative composition. Therefore, when you type the following query into a search engine: “what kind of fabric is satin?”, you can get many links to different types of material, and it will all be satin.

Properties and characteristics of satin:

- durability - the fabric successfully withstands up to 200 washes without loss of silkiness and shine, as well as without the appearance of pilling;

- hypoallergenic;

- breathability - the fabric has “breathable” properties;

- hygroscopicity - the fabric absorbs moisture from the surface of the body;

- thermal conductivity - matter maintains body temperature;

- crease resistance - due to the special weaving of the threads, wrinkles do not form on the fabric;

- drapeability - keeps its shape well;

- does not electrify and does not slip;

- softness, silkiness;

- elegant shine.

Important! Properties such as hypoallergenicity, breathability and hygroscopicity are characteristic only of natural fabric, without the addition of synthetic fibers.

Unique properties of the fabric - shine and wrinkle resistance

Which is better: calico or satin? Which bedding is best?

Calico is also used to sew bedding sets. Calico is as popular as satin, although it is inferior in quality.

- It is less dense, so it wears out faster and retains its properties for up to 120 washing cycles.

- It does not have a structural shine like satin, so it is inferior in appearance. This is due to the fact that these fabrics differ in different ways of weaving threads during production.

- When washed, it shrinks high, up to 7%.

The plain weave of calico makes it less dense and less flexible.

? Nevertheless, bed linen made from calico is in demand among the population. The question is the price.

Calico sets are cheaper than satin ones, and this is also an important indicator in making a decision - calico or satin.

Manufacturing technology

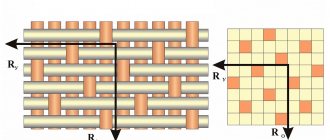

To make satin fabric, two types of high-quality cotton threads are used. One of them, denser, is used for the base of the fabric, and the other, thin and twisted, is used to form the front side. The fabric gets its famous shine thanks to the twisted thread. The reverse side remains matte.

You might be interested in everything about durable cotton fabric of brown-yellow color (nanki)

Important! Satin weaving has its own peculiarity: a twisted thread is woven into the back through three rows into the fourth. The mercerization process gives satin a more pronounced shine.

Satin weave threads

Production of material

Mercerized cotton is used in the production process. The name of this technology was given by John Mercer, who patented the material in Europe. The essence of mercerization is as follows: cotton is alternately soaked in an acid-base solution. After this, the fabric is better colored and acquires good strength. Then the matter itself is created from the threads. The front side is woven with twisted threads, which makes the item shiny. The more the threads are twisted, the more shine the finished product will have.

Varieties by density

The density indicator depends on the number of intertwined threads per 1 cm2 of fabric.

Satin has the following density:

- regular - 85-130 threads; to improve the quality, such satin is mercerized or calendered (passed through heated rollers);

- printed satin - 85-170 threads, threads of different colors are used in weaving;

- printed - 85-170 threads, the design is applied to the finished product;

- jacquard - 170-220 threads, has a double-sided pattern made with a specific weave;

- Mako-satin - from 220 fine threads, very durable fabric of excellent quality.

Distinctive properties of satin

Satin fabric first appeared in China, around the 12th century. At that time, it was a very expensive fabric, available only to wealthy gentlemen, since it was created from natural silk threads.

In Europe, they learned about the material only in the 19th century, and already in the 20th century, silk threads for creating canvas began to be replaced with cotton ones. This made it possible to significantly reduce the cost of fabric.

According to standard technology, the fabric is produced only from cotton fibers. It is very smooth and shiny, soft and wear-resistant.

However, there are often cases when synthetic threads are added to the material to improve quality. This type of satin is called mixed and has better resistance to damage and a longer service life, but is inferior to natural material in softness and silkiness.

If you prefer only natural fabrics, study the composition of the material before purchasing for the presence of additional impurities.

Classification by origin of fibers

The satin weaving method can be used to make fabric from various fibers.

Varies in composition:

- cotton, made from natural cotton, sometimes called ecosatin;

- mixed, made of cotton and polymer fibers;

- satin-double, fabric used for linings, can consist of several combinations of cotton and viscose threads;

- satin-satin or silk-satin, made of silk and cotton threads;

- crepe-satin, made from cotton and silk threads, natural and artificial silk are used;

- stretch satin is a crepe-satin with the inclusion of lycra for elasticity.

Note! There is another type of fabric - satin-twill, or polysatin. This is a mixed twill weave fabric, similar in composition to certain types of satin, mainly cotton and polyester.

Many people are interested in what kind of satin velvet fabric is this? This is a special fabric that is made from threads with pile. Here's an insulated option for winter.

Velvet fabric in soft peach color

Description and properties of the material

The composition of satin fabric can vary greatly, but one feature always remains the same - a large amount of cotton. It feels similar to silk or satin, thanks to a special weaving method.

The satin weave ensures the highest strength of the fabric. You won't be able to tear it like regular cotton. To increase elasticity, elastane and similar synthetics can be added to the fabric. Typically, such mixtures are used for clothing and bedding.

The fabric is hygroscopic and hypoallergenic, so it can even be used for children's bedding and clothing.

Classification by dyeing method

Depending on the method of dyeing, fabric can be of the following types:

- monochrome - bleached or uniformly colored;

- printed;

- printed;

- reactive printing on fabric, resulting in a three-dimensional 3D pattern;

- stripe satin - has one color tone, and the pattern includes stripes, made using partial jacquard weaving techniques.

Printed fabric

Description of satin fabric

Satin looks different from other types of fabrics. This is due to a special method of weaving threads. The main part of the material is dense, and the front part is characterized by smoothness and lightness. The reason for this is the use of thinner threads, which, when twisted, create shine in the fabric.

Satin is often confused with calico and poplin. If you look at the drawing more closely, the difference will become obvious. Calico is represented by a pattern in the form of ordinary crosses, while the pattern of satin material is created much more complex. Poplin is made with a particularly important condition, which is the use of threads of different thicknesses.

You might be interested in this Features of satin: what the fabric is made of, what material is sewn from

Sundress

Product care

Much to the happiness of housewives, satin is not a capricious fabric. Bed linen will not lose its silkiness for a long time, and clothes will still delight the eye with bright colors.

The first wash of the product must be carried out based on the care instructions. Fasten all zippers and buttons, and turn the clothes inside out. The washing temperature is usually set at 40°C, cotton mode.

Caring for satin bed linen

Be sure to wash before first use. It is best to do this in the “cotton” mode at 40°C. In the future, for subsequent washes, it is allowed to set the temperature to 90°C. The use of rinse aid is also permitted. It makes the fabric even softer.

You might be interested in Bengalin features: properties and characteristics of the material

Important information! Since satin is virtually wrinkle-resistant, you can avoid the tedious process of ironing all day by carefully hanging your laundry to dry. If you still want to iron the bedding, you must remember that the temperature of the iron should not exceed 90°C. It is better to iron from the wrong side.

Bed linen care

How to care for satin fabric

Here are a few rules for caring for satin that will help extend its service life and maintain the original strength and attractiveness of bed linen.

- The washing temperature should be 40 degrees Celsius. If there is heavy contamination, it can be raised to 60 degrees.

- You can iron the fabric at a high iron temperature. However, it is better to do this from the wrong side. With this approach, there is less chance of damaging the threads of the fabric.

- Since satin fabric is quite resistant to a wide variety of influences, it is not picky in choosing a powder. You can use any detergent for cotton material.

It should be remembered that all of the above rules apply only to fabrics that do not contain silk. If we are talking about satin or speck, they are washed like silk.

How to choose bed linen

When choosing bed linen, it is better not to skimp on convenience and comfort and choose a fabric with a natural composition of 100% cotton. For sleeping sets, the best choice would be a material with a density of 130 threads per cm2. Since bed linen is in “everyday” demand, we must remember that the denser the fabric, the more durable and wear-resistant the product will be.

Important information! Before purchasing, be sure to unwrap the packaging and touch, touch, and feel the fabric. It’s also worth taking out one item, for example, a pillowcase, and holding it up to the light. A high-quality, solid thing will only let in sunlight or bright electric light. If the outlines of objects are visible, then the material is not dense.

The structure must be homogeneous. If there is a mark on mercerization on the label, this is a strong argument for a positive decision on choice. Smoothness, even silkiness, of the fabric is also a good sign. The roughness of the front side of the product indicates that the product will quickly roll up, pellets will appear and the shine will disappear.

There are several types of fabric from which bed linen is most often made.

Silk satin

This material is a unique combination of silk on the front side of the fabric and cotton on the back, without the addition of artificial fibers. The most durable fabric of truly impeccable appearance, but also the most expensive of all types of satin.

Silk satin bed linen

Printed satin

The thread density is quite high, up to 170 per cm2. On linen made from such satin, the design is applied to the finished product, so the linen looks especially elegant. Underwear with 3D patterns is in great demand. It is obtained by applying an image to fabric using reactive printing. It looks simply amazing!

Crepe satin

A material containing silk, viscose or synthetic threads of special crepe twist.

Printed fabric bed linen

Types of fabric

You will find many varieties of satin on sale. Each material is unique in its properties and characteristics.

Novosatin

Inexpensive material, with predominant artificial fibers similar to cotton. This type of satin is used for sewing inexpensive bed linen.

Satin jacquard

A special type of material that is distinguished by its original weave of threads. As a result, the canvas turns out beautiful both from the inside and from the front side and has a certain double-sided pattern. The fabric is very dense, since a large number of threads are used to create it.

Stripe satin

A type similar to jacquard is stripe satin. The material is no less durable and wear-resistant, with a density of 220 g/cm. Unlike jacquard, it has a characteristic difference in the type of weaving, resulting in a striped pattern, both from the face and from the back.

Macosatin

One of the most expensive types. Made from selected cotton threads produced in Egypt. In the process of creating the fabric, the fibers are carefully combed out, depriving their surface of even the smallest fibers. The result is a perfectly smooth, silky and pleasant to the touch material.

Silk-satin

Sometimes called satin-satin. The material is incredibly smooth on the front side and rough on the back. To create the fabric, only natural silk and cotton fibers are used. It is used to make fine clothing or home textiles.

Crepe satin

Similar to silk, crepe-satin is smooth on the front side and rough on the back. Unlike silk fabrics, artificial silk threads are used to produce the material. This allows you to significantly reduce the cost of products.

Satin stretch

Satin stretch has the properties of a crepe weave, except that the fabric contains additional elastane and lycra threads, due to which the fabric can stretch. Basically, this material is used only for sewing clothes.

Printed

Printed or coupon sateen is a regular fabric with a pattern applied directly to the front side of the fabric. In this case, the design is selected separately for each product. It is considered more environmentally friendly compared to analogues, since the paint does not come into contact with the skin.

Printed

The printed material features an endless pattern thanks to the interweaving of multi-colored threads. This fabric is mainly used to create bed linen.

3D satin

In fact, this is the same printed form. In this case, the drawing is applied to the canvas using special technologies. As a result, realistic “live” images of nature or animals appear on the surface of the fabric.

Gloss satin

Particularly durable synthetic material, which consists of polyester fibers, painted with silver paint using special technologies. This material is mainly used for sewing covers.

Slim satin

Lightweight and thin material made from the finest polyester fibers. This type of bed linen is wrinkle-resistant and quick-drying. The fabric withstands a large number of washes and does not lose color saturation for a long time.

Double-satin

A blended material containing viscose silk fibers. In this case, the warp threads can be cotton or staple yarn. It has a high density and is used mainly as a lining fabric.

Luxury and deluxe

These types of materials have special characteristics. To create the fabric, only natural threads of the highest quality are used. These raw materials are produced in Brazil, Egypt, Turkey, Pakistan, India and the USA. Bed linen marked “luxury” or “deluxe” will cost much more than a set made from classic fabric, but will also last much longer. These are the softest, silkiest and most body-friendly varieties of satin.

Soft satin

The fabric consists of weaving threads of natural cotton and viscose. Thanks to the viscose included in the composition, the material does not wrinkle and does not lose color saturation for a long time, and the product itself does not deform. It is mainly used for sewing bedding sets.

Rotor-satin

The most durable and wear-resistant appearance. Consists of 100% cotton fibers. Used for sewing adult and children's bedding sets.

Mancy-satin

A unique look made from cotton and fleece fibers. The front side of such products is smooth and silky, and the back side is soft and has thermal insulation properties. Similar material is used for sewing blankets and bedspreads.

Staple-satin

Satin weave fabric with a matte sheen on the front side, density from 210 g/cm. The composition is dominated by viscose fibers (95%). It is a silky and smooth material with a tight weave. It is characterized by high drapability, hygroscopicity and softness.

Smart satin

Smart satin fabric consists of artificial cotton fibers created using the latest technologies in the field of light industry. In terms of tactile and performance properties, the material is not inferior to natural cotton, and in some criteria even surpasses it. The fabric does not cause skin or other allergic reactions, lasts a long time, and is resistant to various chemical influences. Such bed linen does not lose color saturation, is easy to wash and does not require ironing.

Satin twill

Not very dense economy class fabric. It is distinguished by a special twill weave of threads. In terms of tactile and quality characteristics, it does not differ from its analogues, but requires the most careful care.

Advantages and disadvantages of bed linen

Its advantages include the following:

- durability and strength - repeated washings practically do not deprive the linen of shine, smoothness and visual appeal;

- Washed items do not need to be ironed; to do this, you need to dry them, carefully straightening them out;

- softness, airiness and comfort for the body;

- does not slip on the mattress due to the dullness and somewhat rough surface of the underside;

- retains heat well, which is especially pleasant in the winter season;

The disadvantages are not so numerous:

- higher (compared to other materials) cost;

- very smooth fabric is still slippery, lying on it in silk pajamas will not be particularly comfortable;

- in the summer months, due to abnormally high temperatures, sleeping on satin linen is still hot.

You might be interested in Description of mouton fur: properties and characteristics of sheepskin fur

Important! These disadvantages are rather relative, since high-quality material is more expensive for objective reasons, not everyone wears silk pajamas, and the concept of hot or cold has always been relative and subjective.

So satin can be considered the ideal choice for sewing bed linen.

Pills on bed linen

Production of satin products

The main purpose of the fabric is the production of bed linen. The material, due to its quality, ensures a comfortable, healthy sleep.

Satin has also found application in home textiles; curtains, bedspreads, and tablecloths are made from it. The ability of fabric to retain its shape and bright colors are used to create home comfort. Textiles make you happy for a long time and lift your spirits.

Clothes are made from satin: men's shirts, women's dresses.

An inexpensive type of satin is used as a lining material for the main type of clothing.

A new direction for satin: using it for stretch ceilings. Interesting fabric material will decorate favorably and make any interior original.

The calm matte shade, in contrast to the mirror surface of glossy ceilings, will advantageously decorate any interior.

Caring for stretch satin ceilings involves wiping off dust with a dry cloth. To remove stains, use a solution with 10% ammonia.

Production technology

Satin is produced in different countries. Its main suppliers: Türkiye, Egypt, Pakistan, China, Italy, Russia. But no matter where it is produced, the technology is approximately the same everywhere. Cotton fibers, which are pre-mercerized, are used as the main raw material throughout. After soaking cotton raw material alternately in a solution of alkali and acid, it becomes stronger and easier to dye.

Classification by type of yarn

In the production of satin, three types of yarn are used: carded, combed and half-combed.

Carded yarn is produced from medium-fiber cotton, a mixture of cotton and viscose, with the addition of chemical and synthetic fibers. Fabrics made from this yarn are not always the same in thickness and uniform in structure. The density of carded satins is from 129 to 150 g/m2.

Some types of satin are produced by jacquard weaving, in which a large-scale pattern is placed on the satin background of the fabric.

Satins are produced bleached, printed, plain-dyed. They use different finishes: mercerization, embossing, silver calenders.

Combed yarn is made from long-staple cotton and long silk fibers, which are oriented along the length of the yarn and straightened as much as possible. It produces a lighter and thinner fabric (density 112-130 g/m2) with a smooth, shiny surface.

Semi-combed satins are made from carded yarn on the warp and combed on the weft, which forms the front surface. They are coarser and heavier than combed satins. Their density is 130-180 g/m2.

Special type of weave

Many types of weaves are used in weaving, which are based on threads located perpendicular to each other. Some of them (the base) are parallel to the edge of the fabric. Others (wefts) - perpendicular to the edge. When they are intertwined, a repeating pattern is formed - rapport. The canvas itself consists of many identical repeats. The number of threads in the weft and warp of rapport in fabrics is different.

The fabric is produced by satin weaving two types of cotton threads. The denser fabric is used to form the base of the fabric - the reverse with a matte surface. Another thread - twisted and thin - is woven on the front side into the back side. But not in every row, but three rows into the fourth. Due to this weave, when the longitudinal thread (warp) more closely overlaps the transverse thread (weft), the fabric becomes soft, silky, and acquires a shine that is enhanced by mercerization.

Bleaching, dyeing, finishing

At the last stage, the finished canvas is bleached and dyed. Mainly in two ways: pigment and reactive.

When pigment dyeing, the pattern is applied only to the front side of the canvas. Coloring pigments do not penetrate the fibers. This method is used for inexpensive types of satin, when you need to create a printed pattern on the surface of the fabric.

Reactive dyeing is a more expensive and complex process. The dye penetrates the fibers, saturating them with intense color, but without changing the structure. The fabric remains as soft as before dyeing. When washed, the fabric does not fade, the paint does not fade and is not washed off for a long time.

At the final finishing stage, the satin fabric is subjected to several more procedures that improve its properties:

- A burnishing or gloss finish in which the fabric is soaked in a solution, gaining some rigidity and a glossy sheen.

- Ironing on special machines - silver calenders. As a result of this finishing, the fabric becomes smooth and has a silvery-silky sheen. But after washing, the special shine quickly disappears.

History of fabric

The main raw material for the production of modern satin is raw cotton, extracted in the form of seeds covered with many individual fibers from the fruits (bolls) of the plant. As they ripen, they are collected, opened, processed, and raw materials are obtained for the production of various fabrics - cotton fiber. Durable, thin, elastic, wear-resistant, hygroscopic.

Satin production began in the Chinese province of Guangzhou. There is a version that “satin” is a distorted name for this geographical feature. According to another version, the name comes from the Arabic word “zaytin”. In English it sounds like Satin-surface - “with a satin surface.”

Medieval satin was very expensive and looked different. Almost like silk. Silk-satin differed from fabric obtained from silkworm threads in that instead of cotton threads, silk threads were woven into the fabric. In the 12th century, bright outfits for special ceremonies were sewn from Chinese satin. The European nobility could also afford fashionable new clothes made from cotton sateen, which reached European countries through the Great Silk Road.

Until the mid-19th century, European countries did not produce this material. Although they tried. Then cotton began to be grown in many countries. In France, a circular weaving machine was invented, which finally made it possible to produce satin fabric.

By the end of the 20th century, cotton fiber became the main raw material of the textile industry. According to statistics, almost 80 countries around the world were cultivating cotton at that time. The Industrial Revolution and changes in technology led to the fact that cotton fabric completely replaced silk threads in the production of satin. This contributed to its mass distribution. The price for it has dropped sharply, the fabric has ceased to be a symbol of luxury and wealth.

The invention of John Mercer helped further reduce the cost and distribution of satin. He came up with a new method of processing cotton, which was called mercerization in honor of the scientist. Its essence is as follows: before obtaining threads from the fiber, it is treated first with an alkali solution, then with an acid. After this procedure, the fiber acquires the shine of natural silk. This is how they learned to make artificial silk thread from cellulose and cotton fiber.

What is satin

Modern satin is a fabric with a smooth texture and shiny surface. Very reminiscent of silk. Strong, durable. It's inexpensive. Such properties are inherent in all fabrics of satin and satin weave, in which the front side is formed by tightly lying weft threads.

Satin is made mainly from cotton that has undergone a mercerization procedure. Sometimes artificial or natural silk, synthetic and artificial threads are added to it. The fabric is most often used for sewing bed linen. According to reviews, many people like underwear made of satin fabric.

Advantages and disadvantages

Satin satin is much easier and more unpretentious to care for than regular satin, stronger and more resistant to the formation of snags on a smooth surface. In addition, it slips less and therefore bedding made from this material is much more convenient to use.

Pros:

- strength;

- softness;

- beautiful appearance;

- ease of care;

- affordable price;

- durability;

- hygroscopicity;

- variety of color palette;

- color fastness;

- pleasant tactile sensations.

Minuses:

- difficulties in working with fabric;

- low level of air exchange;

- The fabric may shrink when washed at high temperatures.

Despite the fact that satin-satin is made using synthetic polyester, this fabric almost never causes irritation and can be used by people with sensitive skin.