Twill weaving is considered one of the most beautiful, while twill fabric is more of a collective name than a specific variety. Its composition can be anything, and the only thing that unites the canvases is the weave. The pattern seems to go at an angle, or rather diagonally. This weave is familiar from jeans and suit fabrics. The diagonal pattern of weaving threads on the canvas is a distinctive feature of the material. Fewer intersections of warp and weft threads with additional offset not only gives the fabric a grainy feel, but also increases tensile strength.

What kind of fabric

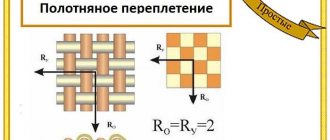

Twill is a fabric with increased density. Not everyone understands what it is and how twill weave fundamentally differs from plain weave. A feature of twill weave is that the weft and warp are shifted by 1 or more threads at each subsequent intersection. The material can be warp and weft, with weave 1/2 and 2/1, 1/3 and 3/1.

The main varieties are considered stronger. In these types, the warp thread forms the front side. In the weft variety, the weft threads predominate on the front side in relation to the warp threads. For the production of technical fabrics and fabrics for workwear, 3/1 fabric of a mixed composition is more often used. Twill weaving also includes tweed, gabardine and twill.

What twill is can be judged only by its name. However, the description differs for different twill fabrics. It can be dense and relatively thin fabric, elastic and low-stretch. Twill is cotton, stretch, silk, and polymers. Twill can be any type of fabric, and diagonal weaving is what unites all the fabrics in this group. Without knowing what the material is made of, it is difficult to judge its characteristics. We can only say one thing - all twill fabrics have increased tensile strength.

Description of fabric and manufacturing features

Twill is an array of fabrics of any composition and purpose, united by an original weaving method. The effect is achieved thanks to a special twill weave pattern, in which the system of fiber intersections is shifted by 1, 2, 3 or more threads. It is formed on the front side of the canvas in the form of a characteristic relief of small and large oblique stripes running across the width of the canvas and often directed to the right.

Although there are fabrics with an indicator (rapport) “to the left” or in the form of a fraction with the numerator from the size of the main overlaps and the denominator from the weft overlaps. Small rapport gives a small and frequent diagonal pattern. At larger values, a large scar of tubercles is obtained.

In any case, the diagonal weave produces a dense twill with a high degree of internal mobility. When the material is stretched, two threads are under load at once.

The name of the fabric is based on the Latin word “sericus”, that is, silk, due to the first samples of twill made from silk fibers. In the mid-19th century, twill weaving became the basis for the production of denim. Today, the composition of raw materials can be very different.

Compound

Twill does not have one composition; it can be 100% natural fabric, mixed or synthetic. Twill lining fabrics, according to GOST, have a chemical, that is, artificial composition. Typically, twill weave is used to produce wool, cotton and silk fabrics. Just remember denim or tweed.

Reinforced twill with expressive relief is widely used in the manufacture of outerwear. In this case, there is not only a high density of the material, but also a significant thickness. The group of reinforced fabrics includes coat fabrics of a wool blend composition, as well as tartan and some costume and dress varieties.

For suiting fabrics, broken twill is more suitable, which forms a herringbone pattern. The composition of such cuts is predominantly cotton or wool, sometimes mixed. Reverse twill also has a distinctive texture and is suitable for suiting. The composition of such cuts is similar - wool, half-woolen, cotton.

Twill fabric has other composition options. Semi-silk fabrics with cotton weft and a silk warp are common. They are dressable and suitable for making light clothing.

The main types of weaves of textile fabrics.

Hello!

Several times in my previous articles I have used the phrase “interlacing of textile threads.”

Let's delve a little deeper into this topic today, but just a little. Let's not get to the bottom of the details. After all, we are simple consumers and are not going to study to become weavers or take exams at a textile institute.

So, fabric is a textile fabric made on looms by interweaving threads. Some threads run along the fabric and are called warp threads, others run across the fabric and are called weft threads. These threads are located perpendicular to each other.

And the way they are intertwined ultimately determines what the front and back sides of any textile fabric will look like, its strength, thickness, extensibility, frayability of open sections, ability to be molded during wet-heat treatment, etc.

Types of fabrics for clothing.

Fabrics for sewing clothes.

Dividing fabrics for sewing clothes into light, medium and heavy.

How to choose the right fabric?

The main types of weaves of textile fabrics.

What do the signs on clothing labels mean?

The type of weave of the fabric threads also affects the choice of the model that will be made from the fabric and its behavior during cutting and sewing.

The threads of the textile fabric are intertwined in the wrong way, or randomly. There is a strict procedure in this matter.

Weaving weaves are divided into 4 classes.

- Simple.

- Finely patterned.

- Complex.

- Large patterned.

Plain (plain or warp) weave.

These weaves include plain, twill, and satin (satin).

Plain weave.

Plain weave is the most common and strongest, and with higher density it has increased rigidity. Fabrics made using plain weave cut well. In plain weave, the warp and weft threads alternate one after another in a checkerboard pattern.

When, in a plain weave, the warp thread is thinner than the weft thread, a transverse hem appears on the fabric and such weaves are called false rep. Poplin, taffeta, etc. are made in this weave.

The front and back sides of the fabric with this weave are identical and have a smooth, matte surface.

Made with plain weave: from cotton - chintz, calico, cambric, etc.; from linen - linen, canvas, trim, etc.; from silk fabrics crepe de chine, crepe georgette, crepe chiffon, etc.; from woolen fabrics - cloth, suits and dresses, etc.

Twill weave.

Twill weave forms a visible diagonal rib on the surface of the fabric, which runs either from top to bottom and left to right, or from top to bottom and right to left.

Typically, diagonal scars run at an angle of 45⁰. If the density of the fabric increases, then the diagonal rib becomes steeper or more shallow.

Fabrics produced by twill weave are denser, thicker and heavier than plain fabrics and are somewhat inferior to them in strength. But they are smoother and more abrasion resistant. They have greater elasticity, stretchability (especially diagonally) and drape.

Since fabrics made with twill weave stretch more easily, they require more attention when cutting to avoid distortions.

Most often, such weaving produces wool blend fabrics (on a cotton base and with a wool weft thread - tartan), semi-silk (silk warp and cotton weft - twill), as well as cashmere, gabardine, etc.

Satin (satin) weave.

Satin and satin weaves are distinguished by the fact that they have a smooth and even surface with increased shine, which is formed from the rare interweaving of the warp and weft threads. If the right side of the fabric is formed from weft threads, then the fabric is called sateen, and the weave is sateen.

If the front side of the fabric is formed from the main overlaps, then the fabric is called satin, and the weave is satin.

A periodically repeating pattern of these weaves (rapport) is built from different numbers of threads 5/2.7/2.7/3.8/3.8/5.

Satin and satin weave make it possible to print a pattern very clearly on the surface of the fabric and increase the wear resistance of such fabrics. They are very soft and elastic.

But fabrics produced by such weaves, especially silk, have increased slip and fraying of cuts.

Some cotton (satin), linen and silk fabrics (satin, crepe-satin, etc.) are produced using satin and satin weaves.

Finely patterned.

Finely patterned ones are further divided into two classes. Derivatives from simple ones (from plain weave - rep, matting, from twill - reinforced twill, complex twill, broken and reverse twill, diamond, etc., from satin and satin - reinforced satin, reinforced satin) and combined (crepe, diagonal, composite, waffle, combined twill, etc.)

Rep weave.

Rep weave is a derivative of plain weave. It is characterized by the formation of a scar on the surface of the canvas.

Due to the sparser weave of the fabric threads than plain weave fabrics, fabrics produced by this weave are softer and less stretchable.

When cutting fabrics with such a weave, you must strictly ensure that the scars on the parts of the clothing have the same direction.

Weave matting.

The matting weave is also a derivative of the plain weave. The pattern of weaving threads on the canvas is more pronounced than in plain weave.

Fabrics produced with this weave are denser than with plain weave, quite soft and elastic.

This weave produces cotton and linen fabrics, as well as some woolen and wool-blend costume and dress fabrics.

Reinforced twill.

The pattern of weaving threads on the fabric, with reinforced twill, has pronounced wide relief diagonals. The properties of fabrics produced by this weave are the same as those of fabrics with a simple twill weave. This weave is used to produce costume and dress fabrics (tartan, cashmere, flannel) and some coat fabrics. And also cotton and silk twill.

Complex twill.

This weave is characterized by the presence on the fabric of several diagonal stripes of varying widths. Fabrics produced by this weave have the same properties as twill weave fabrics.

Some costume and dress fabrics are produced in this weave.

Broken twill.

Broken twill is created by changing the direction of the diagonals of the twill at right angles, resulting in a herringbone pattern in relief.

Broken twill weave is used in some cotton and woolen suiting and dress fabrics.

Reverse twill.

Reverse twill differs from broken twill in that at the break points the diagonals shift; opposite the diagonals from the main overlaps are the diagonals from the weft overlaps.

Reinforced satin (reinforced satin).

Reinforced satin (reinforced satin) is a weave that is formed by strengthening the main overlaps in satin and the weft overlaps in satin. This increases the strength of the fabric. Combined weaves (crepe, diagonal, composite, waffle, combined twill, etc.)

Crepe weave.

Crepe weave is a modified plain and matting weave. As a result of the elongated main overlaps randomly scattered across the surface of the fabric, such fabrics crumple less and are easy to cut.

Crepe weaves are widely used for the production of dress fabrics.

Composite (combined) weaves are formed from two or more different weaves. Such weaves can consist of plain and rep weave, twill and matting, twill and satin, satin and satin, satin and crepe, etc. These weaves are used to produce suiting fabrics, trouser fabrics and sometimes dress fabrics.

Complex - double-faced, double-layered, pile, pique, looped, leno (lace).

Double weave.

Double-face weaves are formed from three systems of threads: two warps and one weft or one warp and two wefts.

Double-face weave fabrics are characterized by greater thickness, density and surface density, high heat-protective properties and wear resistance.

Thin-woven coat fabrics (drape, velor, etc.) and some silk and cotton fabrics are produced using double-face weave.

Double layer weave.

Two-layer weaves are formed from four or five thread systems: two warps and two wefts, two warps and three wefts, three warps and two wefts.

Such weaves form two independent fabrics, located one above the other and connected to each other either by one of the systems of threads that form these fabrics, or by a special warp or weft thread.

With the help of this weave, thick, dense, heavy, fine-woven coat fabrics and some silk suit and dress fabrics are produced.

Pile weaves.

Pile weaves form a pile on the surface of the fabric. These are thick, protruding ends of the fibers.

This weave produces very beautiful and wear-resistant fabrics. The pile protects the fabric well from abrasion and wear.

Fabrics made with pile weave with a rib, for example, corduroy, must be cut so that the direction of the rib on all parts is in the same direction.

Large-patterned (jacquard) - simple and complex large-patterned.

Large patterned weaves are produced on jacquard weaving looms. They are all very complex and diverse. These include various ornaments, flower arrangements, portraits, etc.

Large-patterned weaves are divided into two groups: simple and complex.

Simple large-patterned weaves are formed from two systems of threads by a combination of simple, derivative and combined weaves.

Cotton jacquard sateens, linen tablecloths, towels, napkins, etc. are produced in this weave.

Complex large-patterned weaves are formed from three, four or more thread systems. Tapestries and other fabrics are produced using this weave.

In general, as I already explained, there are many weaves, but we, ordinary “users” of textile industry products, need at least basic knowledge about all of them. After all, you never know where or how they might come in handy.

For example, plain weave. Apparently earlier, at the “dawn” of Soviet power, when even crazy queues lined up for chintz, it was invented, by a decree of some All-Russian Central Council of Trade Unions, to quickly serve customers, tearing the cuts with your hands. After all, the plain weave breaks strictly along the transverse thread.

I myself had the “pleasure”, but already in our time, without shortages and without queues at the fabric store, to encounter such a saleswoman - a “quick worker”. There is no one, and she is too lazy to cut with scissors. In general, I didn't like it. And the edge of the canvas was slightly deformed. And in response to my grumbling, she said that they were allowed to do this according to the instructions.

Or satin weave. As I have already “stitched” above, all textile fabrics with satin weave are prone to increased fraying of open cuts.

So, even slightly touching on the topic of weaving threads of textile fabrics, we learned a lot about them.

See you in the next article! Sincerely, Milla Sidelnikova!

Types and their properties

Twill fabrics are varied. They differ in structure, density, characteristics, and purpose. Woolen or wool blend twill is used primarily in the manufacture of suits. The group of woolen fabrics with twill weaving includes gabardine, tweed, and cashmere. Cotton and silk twill are lightweight and breathable. She goes to make summer clothes. Twill, a durable cotton fabric with a rich palette, has become widespread.

Let's name other varieties:

- lining – smooth viscose twill for making linings for outerwear, dresses, skirts, etc.

- Stretch twill is a common type of fabric used for form-fitting clothing such as skinny pants and leggings. Elastic fabric - the same stretch denim used for sewing tight jeans;

- Severe twill is a durable and coarse cotton-based fabric with the basic properties inherent in all twill fabrics. Used for the production of workwear;

- Bleached twill is a type of harsh fabric that has only been dyed. Subsequently, a pattern is applied to it or evenly painted over. Thus, black twill is suitable for sewing trousers and business suits, and printed fabric is recommended for making dresses, blouses, and home textiles.

Review of matters

The yarn used for twill weaving has the same effect on the properties of the finished fabric. The versatility of the fabric lies in the use of various fibers (artificial and synthetic). Denim fabric is often made from it, it can be:

- One of the cheapest and thinnest materials is Gin, produced from untwisted yarns of low density;

- Jeans. High-quality and dense material, the weft threads are twisted. Recently, elastane has often been added to denim to make it more elastic;

- Stretch. There are also warm denim, with thermal material on the inside as a lining;

- Denim with a ripe herringbone pattern is called Broken Twill. The first jeans were made from it;

- One of the most expensive and best fabrics will be Denim and Selvage. Jackets, coats, and suits are made from them.

To visually understand what is being said, you need to watch several master classes on weaving.

Material Denim

Wool twill

Basically these are quite dense and warm fabrics. Twill wool is used to create winter clothing.

What does gabardine look like?

What fabrics are made from wool twill

- Gabardine is a material made from merino sheep wool. Fur coats, coats, and sweaters are made from it. Used as furniture upholstery. She looks quite elegant. The peculiarity of this fabric is that the scar on the outer side is tilted at 60 degrees and the back is shiny;

- Tweed - hats, suits and coats are made from this fabric. Made from sheep's wool. Properties of the fabric: keeps warm, does not wrinkle, has a beautiful appearance.

You might be interested in what double-thread means: description and use of Turkish fabric

Mostly suits, outerwear, hats or demi-season items are made from woolen fabric.

Wool blend

For twill weaving, mixtures of threads are used. Wool blend fabrics are very popular. Cotton yarn is used as the warp, woolen threads will be used as weft. They are most often used to make coats and special clothing for workers. It is quite difficult to care for, so you need to follow the rules written on the label.

Natural silk twill

Cotton

Pure cotton fabrics are very dense. Such material is called harsh.

One of the most beautiful and popular fabrics to use will be denim fabrics with a pattern, they are called jeans. For the base in the canvas, dyed yarn is taken.

Silk and semi-silk

Silk twill fabrics are used to make sets of linen that are soft and pleasant to the touch. For semi-silk fabrics, silk fabric and cotton weft are used.

Viscose

Viscose thread is made from cellulose. Thin viscose twill fabrics are widely used as linings in hats or outerwear. Many women's wardrobe items are made from the material. For example, autumn dresses or office suits.

Lining material

Flaws

The disadvantages of the material are determined by its composition. If we are talking about cotton varieties, they shrink, although they are easier to work with when cutting. If you carry out wet-heat treatment before cutting, subsequent deformation can be avoided.

The presence of wool fibers increases the care requirements. In addition, woolen material is of interest to moths and can cause skin irritation in allergy sufferers. When purchasing twill fabric, you should carefully study its composition so as not to encounter unpleasant surprises in the future.

Material characteristics

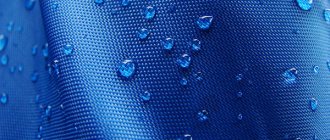

Twill is widely used in various industries due to its high performance indicators:

- Good breathability. In such clothes, the skin “breathes”, which eliminates the greenhouse effect, sweating and, as a result, the unpleasant odor of sweat.

- Strength. The material is difficult to tear. It is resistant to mechanical damage: punctures, tightening. This quality is ensured by high density - 220-360 g per square meter. Even with minimum indicators - 219-220 g/m2. meter fabric is not blown by the wind.

- Hygroscopicity. Twill absorbs moisture well, but also releases it easily, which ensures quick drying.

- Good thermoregulation. That is why twill items are not hot in summer and warm in winter.

- Non-electrifying. Twill does not accumulate static electricity and does not “spark.” This allows it to be used for sewing workwear for chemical industry workers.

- Suitable for impregnation. The fibers absorb various compounds and become resistant to oils, moisture, and chemicals. This is especially true for varieties that are used for technical purposes.

Double-sided varieties have the best tactile characteristics. They are softer and more pleasant to the touch. Therefore, they are chosen for sewing women's and children's clothing.

Application area

Rough fabric is suitable for workwear, work suits, and protective equipment. Military clothing is also made from a harsh variety; just look at the common camouflages: flora, pixel, etc. The cotton variety is used for foot wraps.

Bleached twill is used for medical clothing and work suits. It is used to make white medical gowns and men's and women's suits for food production. Materials with protective impregnations are used in various fields. Fire-resistant overalls for welders or women's work smocks used in chemical production may have the same twill weave.

Viscose twill is used as a lining fabric. Thin cotton varieties of twill are used for sewing summer suits and dresses. Buyers especially appreciate thick cotton twill shirts; just look at the blue and light blue denim models. They never go out of fashion and are popular with men and women of all ages.

Twill fabrics are often used when sewing bed linen. Such sets will delight you with durability and comfort. Cotton fabric is pleasant to the body, does not pill, “breathes”, and absorbs moisture. This kind of underwear is not budget, but it is superior in performance to sets made of poplin or satin.

Description, characteristics and properties of twill fabric

Fabrics with twill weave have the following quality characteristics and properties:

- High heat transfer property, like viscose.

This fabric will be comfortable at any time of the year: twill will not be cold in winter and hot in summer. This quality is important both for everyday clothing and for specialized ones.In addition, twill curtains will allow less cold air to pass through the window if there are cracks.

- Hypoallergenic . This is absolutely non-allergenic material, since it contains at least 70 percent cotton. Contact between the skin and the material is painless and does not cause any discomfort.

- Ability to accumulate static voltage . Thanks to special impregnation, it can accumulate static voltage.

- Wear resistance . This is a very practical and durable fabric, it can be produced in different densities from 220 to 360 grams per square meter.

- Water resistance . To improve the quality characteristics, twill is impregnated with water-repellent solutions, so that the material does not allow moisture to pass through. The canvas is also impregnated to repel oils, which makes it convenient to use in technical areas where work involves oils.

When do you need a high sleeping pillow?

Here you can read reviews about diving fabric.

Description and reviews of polysatin fabric: .

The qualitative characteristics of curtain and drapery fabrics with twill weave largely depend on the qualities and properties of the yarn itself, which is used in production.

As an example, let’s imagine the quality characteristics of camouflage twill. This is a cotton material with high wear-resistant properties. Due to the special weave for which twill is famous, the material has high elasticity and strength, which makes it practical. Camouflage twill is an environmentally friendly fabric due to the fact that it contains natural fibers. The high-quality yarn used in its production has an increased ability to withstand breaking loads.

Camouflage fabric has excellent color fastness, hygroscopic properties and airtightness. Widely used for sewing trousers, military camouflage suits and various kinds of uniforms. This type of fabric is suitable for sewing clothes for outdoor activities, as well as for paintball and airsoft. The fabric is breathable and comfortable to wear.

Care

Information about care is given on the product label, because it is the composition that determines how to properly care for the material. But there are basic principles that must be followed when handling twill fabrics:

- the optimal temperature for washing is 40ᵒC;

- spinning and tumble drying are only suitable for harsh twill;

- The washed product should be ironed from the inside out, preferably through the fabric.

Most twill fabrics do not tolerate the use of bleaches, but they tolerate oxygen stain removers well. It is clear that caring for gabardine and twill will be different from caring for denim. Silk and wool varieties are considered the most capricious. And the easiest way to care for cotton-based products.

Dear readers of the Tkan.Club website, if you still have questions on this topic, we will be happy to answer them. Leave your reviews, comments, share stories if you have dealt with this material! Your life experience may be useful to other readers.

A little history

Matter has an ancient history. It appeared back in 300 AD and was used as a working canvas for a long time. There were no complaints about the textiles, thanks to its density and wear resistance. The gray, non-staining shade, which is so important for technical fabrics, was also valued.

The painting gained worldwide fame in the mid-19th century. It was then that Levi Strauss drew attention to him and sewed the first jeans that won the hearts of the workers. The last century brought denim to fashion catwalks, and twill weave gained worldwide popularity. Today, workwear, suits, home textiles and even bed linen are made from the material with a collective name.

How to care for twill?

Following simple recommendations will help maintain the attractive appearance of the material:

- For products with silk and synthetic fibers, the correct washing temperature is important - if the water temperature is above 60 degrees, the fabric will quickly lose its appearance.

- Cotton twill is less fussy. Thick fabric can be washed on an intensive cycle, and thin fabric on a delicate cycle (the temperature can be 60 degrees or higher in both cases).

- Cotton twill can be treated with chemicals (disinfectants, antimicrobials), if necessary. But it is better not to use bleach with chlorine.

In order not to spoil the item, study the manufacturer's recommendations for caring for it. The label should indicate the optimal washing and ironing mode. It is not necessary to iron twill fabrics - they practically do not wrinkle . But if this is still necessary, iron silk textiles at the “silk” setting, and linen and cotton textiles at a temperature of about 80 degrees.

Any type of cleaning can be used. You can remove fat from the lining with a swab soaked in alcohol. If the contamination is strong, and the material is very thin, and you are afraid of damaging it, take the item to the dry cleaner. Always pay attention to the composition of the material.

A few words about the shortcomings

Previously, a tendency to shrinkage was considered a drawback. This was especially relevant for species with a predominance of cotton in the composition. But modern technologies make it possible to produce deformation-resistant fabric. This even applies to cotton options.

Twill causes some difficulties when working with it. Its edges are very crumbling. Therefore, novice seamstresses sometimes have difficulty cutting.

Scope of application of twill

There is probably no industry where twill is not found. It is used for various purposes:

- Hard and rough material that does not undergo additional processing becomes the basis for abrasive cloths, transport and fastening belts, and other technical items.

- Severe twill is the basis of bags, work gloves, shopping bags, and aprons.

- Uniforms for workers in various industries: food, gas, oil, medicine, trade.

- Casual and festive wear. Woolen varieties are ideal for creating warm hats, jackets and other outerwear. Silk, cotton, with the addition of elastane are used for sewing dresses, sweaters, and underwear.

- Textiles for home. Curtains, tablecloths, napkins, oven mitts - all these things act as an original decorative element and provide convenience in everyday life.

- Lining fabric. We are talking about materials with viscose in the composition. Initially, twill was used for precisely this purpose - for lining in the production of outerwear. Sometimes polyester is added to the composition, which increases wear resistance, elasticity, and eliminates creasing.

- Furniture upholstery. Only fabrics treated with special compounds are suitable. Most often water-repellent, antimicrobial.

- Bed dress. We're not just talking about sheets, pillowcases, and duvet covers. Mattresses are also made from twill. It holds the filler well, provides good air exchange, which prevents the accumulation of dust.

You can often see strange abbreviations on labels. VO means fabric with water-repellent properties. MVO – with oil and water repellent.