Type and general description

Lurex is the name of a special type of metallized thread, which is obtained by covering thin and shiny metal fibers with a dyed polyester film, giving the yarn a characteristic shine. The metal commonly used is aluminum, but also brass, nickel and copper.

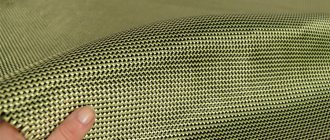

Various fabrics with lurex

Lurex is produced using the lamination method. Metal threads are placed between two layers of polyamide (polyamide film is most often used, but sometimes polyester or viscose is used instead), after which the metal is sealed inside under pressure and at high temperature. The fibers are then cut into longitudinal strips and formed into a thread.

Lurex is called both a shiny metal thread (it is too hard and brittle, so it is not used on its own), and a material or yarn with its addition. Lurex fabric is made by weaving a metal thread with other fibers, which can be either natural or synthetic.

Lurex fabrics are produced in many countries. The Russian market presents mainly products from China, Korea, Turkey, and Italy.

Lurex in fashion history

The real boom of Lurex fashion, the founder of which is considered the famous clothing designer Bill Gibb, occurred in the eighties, when the shiny material became a must-have accessory to the disco style . The fascination with sparkling fabrics has literally captured all levels of society and all age groups. A shiny thread was present in elegant clothes for children and scarves for pensioners; it became an indispensable attribute of a party and was present on office blouses and men's shirts; Lurex textiles were also used for bags and as upholstery material. Lurex knitwear became a particular favorite. Silver and golden glitter created very expressive optical effects on tight-fitting knitted blouses and dresses, enlivened winter hats and warm scarves, and made slender legs covered in tights with a golden sparkle irresistible.

Mass production of inexpensive and not very high-quality clothing, which was in great demand due to its fashionable shine, soon led to a logical result: they began to speak of Lurex ironically, considering it an attribute of not very good taste. However, as with the notorious leopard print, shiny materials have continued to be in strong demand, not only in mainstream fashion, and have now become a sustainable trend that is present in almost all styles of clothing.

Models made of fabric with metallic thread are constantly presented in the collections of Louis Vuitton, Gucci, MaxMara and other high fashion authorities. Clothes that are literally shiny can be seen on many celebrities. This fabric is often chosen for the outfits of Eva Longoria, Pamela Anderson and other stars.

Origin story

People began decorating fabric with inclusions of precious metals a very long time ago. Researchers claim that the ancient Egyptians, as well as the inhabitants of Babylon and Persia, did this. First, the plates of gold and silver were rolled out to the maximum degree of thinness and the thread was pulled out. Then the production was improved: a silver thread with a thin layer of gold applied to it was wound onto a silk thread, which was the basis of the fabric.

The shiny thread we know was invented in 1946 in the USA. Since then it has gone through several modernizations, but still bears the old brand name Lurex, which is a global brand in the production of metallized threads.

In the early 1960s, tobacco giants began using lurex thread to quickly and easily open cigarette packs. In the 1970s-1980s, clothing with lurex became a symbol of glamor and a must-have attribute of nightlife.

By the end of the 20th century, the fashion for lurex ceased to be widespread, and the fabrics themselves with shiny threads became more restrained.

The demand for shiny fabric has not disappeared. In 2021, the company will launch a new B2C fashion collection under its own brand MAISON LUREX with the opening of the first flagship store in Paris.

Composition and properties of the material

In modern materials, the content of metallized thread ranges from 3 to 30% , depending on the purpose of the fabric. Lurex is mixed with almost any fiber - cotton, wool, viscose, silk, linen, synthetics. The fabric also contains dyes added to the polyester sheath of the thread, which allows you to achieve a wide variety of color effects.

If the fabric contains a small percentage of lurex thread, then its properties practically do not change, but outwardly it seems that the surface of the fabric is strewn with tiny gold or silver dust.

A high percentage of thread in a polyester film gives the material the following qualities: abrasion resistance, low electrical conductivity and strength.

Metal foil thread, on the contrary, increases the electrical conductivity of the fabric. In addition, it is harsher and can cause discomfort on sensitive skin.

There is Lurex, which is produced with threads based on brass, copper and nickel. It conducts electricity well and is used in electrical engineering and electronics.

There are common properties inherent in all fabrics with added metallized thread:

Retains shine for a long time

Durable

Do not lose color even after numerous washes

As for the lurex thread itself, it is convenient because it can be worked with on a regular loom.

Advantages and disadvantages of fabric

Guipure looks elegant and gives femininity; it has a lot of useful and distinctive characteristics.

- Easy to use and practical.

- Aesthetics and beauty.

- Lets air through.

- Versatility.

- Lightweight (weighs very little).

- Medium degree of elasticity.

- Retains excellent appearance even after many washes (only if the care rules are followed).

Disadvantages of fabric:

- Deforms if not properly cared for.

- The material is very thin, so there may be snags.

- Difficulty of execution.

- Due to its transparency, it needs to be combined with other fabrics.

- The manual weaving option is expensive.

Pros and cons of the material

Advantages of the material:

- Versatility.

- Softness.

- Flexibility.

- Strength.

- Compatibility with other fibers.

- Good electrical conductivity.

- Hypoallergenic.

- Resistant to chemical agents.

- Ability to retain shine and color for a long time.

- Resistant to sea water.

- Possibility of dry cleaning.

- Spectacular appearance.

Cons of Lurex:

- Heavy weight.

- Tendency to oxidize metal fibers.

- Difficulties in working with the material.

- High price.

Photos of dresses with lurex

Look: Loose dresses - fashion trends and popular cuts this season (125 photos)

Help the project, share on social networks

0

Standards and norms for manufacturing

The production of fabrics containing metallized thread is regulated by the requirements of GOST 29223-91, which applies to ready-made dress, dress-suit and suit fabrics produced from a warp: from chemical fibers, a mixture of chemical and cotton fibers (cotton fibers less than 50%) and weft : from all types of fibers and threads.

GOST, in particular, states that synthetic raw materials, dyes and other chemicals used for the manufacture of fabrics must be approved for use by state sanitary inspection authorities.

It also says that the color fastness of fabrics falling under this standard, assessed on a 5-point scale, must correspond to the highest 5th point.