In order to increase the protective properties of textile materials, innovative technologies are widely used in the textile industry. Thanks to the painstaking work of scientists, new fabrics are emerging that can withstand heavy loads in extreme conditions.

Many of us have encountered membrane materials more than once. But few people clearly understand what polyurethane is, how and why it is used in textile production.

Description

Polyurethane (PU) is a synthetic material of the elastomer group, similar to rubber. Cloths made from chemical fibers have the ability to stretch up to 200% and return to their original state without traces of deformation.

To understand what kind of material polyurethane is, you need to take a brief excursion into the technological process. The polymer, called PU, contains urethane bonds in the main chain. Their length in a macromolecule is several times greater than the transverse parameters. Thanks to this structure, connections gain flexibility and mobility in individual areas.

During the polymer synthesis process, certain parameters are set, obtaining polyurethane fibers with different properties depending on the purpose. Textile structures are obtained by secondary inhomogeneous twisting of the original raw material with synthetic or natural threads. The result is fibers to create elastic materials.

The technology includes the synthesis of a polymer in a special composition, processing of the resulting mass: the production of threads or a component for coating the base. The material's properties are similar to rubber, but it is more elastic and in many ways superior to it.

Eco-leather, a synthetic leather substitute, is made from polyurethane. The material is durable, wear-resistant, and affordable. It has many advantages, surpassing expensive natural leather in terms of performance characteristics. PU is lightweight, frost-resistant, exhibits high tensile strength and is easy to maintain.

What is the difference between PU leather and genuine leather?

PU leather, made entirely of polyurethane, imitates the structure and structure of natural material in appearance, properties and quality. There are more similarities between them than differences. Both types of leather do not change properties in the cold, maintaining plasticity and softness at sub-zero temperatures.

In terms of breathability, eco-leather is almost equal to natural leather: it “breathes” well and absorbs moisture. In terms of texture and smell, artificial leather almost completely imitates the properties of natural material thanks to fragrances and special processing. The PU material, depending on the base, is not inferior in elasticity to its natural counterpart, which stretches well without tearing.

At the same time, PU leather is a more durable and wear-resistant material. Genuine leather becomes abraded over time. The artificial analogue is more resistant to ultraviolet radiation, chemicals, high temperatures and does not form abrasions. Another advantage of PU leather is its price. Products made from this material are several times cheaper than those made from genuine leather.

Signs by which you can distinguish genuine leather from PU leather

It is very difficult to distinguish high-quality PU leather from natural leather by external signs. It will be just as warm when you touch it and will smell just like natural. If you drop a few drops on the material, natural leather, like PU leather, will immediately absorb it and darken. But if the fabric base is visible on the cut, this is a sign that the leather is artificial. In addition, the cut edge of genuine leather is slightly thicker.

You can navigate by the label, which contains information about the lining and base of the product. But here you need to learn to understand what this or that marking on the tag means. For example, the sign “skin with a diamond” shows that the clothing is made from defective natural fabric coated with polyurethane. The diamond-shaped sign indicates an artificial analogue. The hash mark is an indicator of the textile composition.

Composition - decoding of PU value and formula

Polyurethane is safe for health, which is why the name received the prefix “eco” (eco leather). This is a porous multilayer material obtained by synthesizing organic and inorganic components: polyethylene, rubber, cellulose.

The composition of the eco-friendly material is mixed; it contains various chemical elements. Animal skins are not used in production, which helps preserve natural resources.

Expert opinion

Alyona

Fabric expert and technologist Alena Khlebnikova is ready to answer your questions.

Write to us

It is difficult to distinguish eco-leather from its natural “double” from a photo. The material has a similar texture and outwardly resembles the pattern of the epidermis. The composition of polyurethane fabrics for the manufacture of leather goods, upholstery and clothing includes different components: cotton fabrics as a base, a pressed layer from tannery waste, and a polyurethane coating.

PU fibers are used in the production of textile materials: lycra, spandex, neolan, vorin. These fabrics contain from 2 to 5% polyurethane fibers. A typical representative of the group is Oxford material, as well as technical textiles with one- and two-sided polymer coating.

The formula of a urethane group polymer looks like this: −N(R)−C(O)O−, where R is H (hydrogen), alkyl, aryl or acyl. In chemistry, the substance is called PolyUrethane, hence the abbreviation for the material - PU (PU, PUR).

Specifications

PU leather is often found on the labels of leather goods and clothing products; what it is, the description of the main properties given in the table will help you understand:

| Characteristics | Indicators |

| Raw material type | Synthetic |

| Purpose | Production of footwear, clothing, furniture upholstery, technical products (including medical) |

| Density, g/m2 | 500 ± 50 |

| Standard width of canvases, cm. | 140 |

| Water resistance | High |

| Hygroscopicity,% | 1 – 5 |

| Moisture absorption rate | Minimum |

| Fabric structure | Natural or synthetic base with polyurethane coating |

| Side | Right front |

Open to see the entire table

| Air exchange indicators | Minimum |

| Vapor permeability | Low |

| Electrification | Minor |

| Tensile strength | High |

| Peculiarities | When heated and deformed, it does not lose its properties. With high hardness, it remains elastic and does not crack in the cold. |

| Dynamic voltage limit, t, °С | 120 |

| Deformation limit, % | 350 |

| Pressure resistance, MPa | 50 |

| Temperature range, t, °С | + 60 ÷ — 70 |

| Coloring methods | Plain painted monochromatic coating |

| Color palette | Extensive |

| Manufacturer | China, Russia, Belarus |

| Standardization | GOST R ISO 7617-3-2011 |

| Price | Affordable, on average from 500 rub. for 1 meter |

Trendy item for a fashionable boy

The Z-930 jacket is also stylish outerwear, created taking into account European trends, which were adapted specifically for the Russian climate. One of these trends is large briefcase pockets, sewn on the sides of the jacket and fastened with a zipper. In fact, they can replace a fanny pack, they are so roomy.

A knitted wristband is also a trend: similar elements are present, for example, in modern teenage hoodies and sweatshirts. We decided to add them to outerwear, because such wristbands are not only very fashionable, but also make the jacket warmer.

Individual elements - straps, clasps, stoppers - are made in the logomania style, with large and noticeable contrasting inscriptions.

Jacket Z-930 made of rip-stop fabric with polyurethane coating is modern outerwear for the modern teenager: active, inquisitive, who strives to dress comfortably and stylishly.

Is polyurethane harmful to humans?

Polyurethane is an environmentally friendly type of synthetic raw material that is harmless to human health. In the process of its production, formaldehyde, freon, asbestos and other chemical components that can release highly volatile ether fractions are not used.

It is worth considering that the material does not provide optimal air exchange and vapor conductivity. Therefore, the use of PU in clothing and footwear has some limitations. In particular, clothing made from this textile is not suitable for long-term wear during the day.

Properties and characteristics

After reading the list of properties, you can better understand what kind of material it is, polyurethane fabric.

- Visually, it is practically no different from genuine leather, except on the reverse side;

- It stretches very well and does not crack;

- Air circulates well through micropores, so such clothes and shoes breathe well;

- Has good thermal conductivity;

- Does not allow water to pass through;

- Withstands sub-zero temperatures down to minus 30 degrees;

- The fabric is hypoallergenic and non-toxic;

- Very durable and strong, resistant to mechanical stress;

We will tell you how to clean suede sneakers without ruining them in another article.

Of the minuses, we note its sensitivity to ultraviolet radiation. If exposed to direct sunlight, the fabric may fade. Also, polyurethane does not withstand contact with chlorine. After getting wet, the material should be wiped dry to prevent streaks from forming.

As you can see, the properties of polyurethane fabric clearly explain its popularity in the textile industry. Of course, when choosing which is better - polyurethane or leather according to its characteristics, people lean toward natural material. But, do not forget that its cost is several times higher than eco-leather. And also, during the production of the latter, animals do not die, which, in our opinion, is also important. We will give instructions on how to wash a parka in another article.

Well, we studied the characteristics of the polyurethane material and gave it a detailed description. Clothes made from this fabric are suitable for everyday wear. You need to take proper care of it - treat it with special creams and sprays, wash it on a delicate cycle, without spinning or machine drying. With proper care, things will faithfully serve you for many years without losing their original shape and appearance.

It so happens that people are distrustful of synthetic leatherette, considering it almost life-threatening. Of course, it is wrong to think so. All materials for tailoring today are manufactured strictly in accordance with GOST standards, which eliminate the slightest risk to health. If you still think so, we advise you to carefully re-read what it is - polyurethane fabric.

To avoid purchasing low-quality goods, just buy things from trusted brands and don’t go for genuine leather. There is now a campaign for faux or synthetic leatherette all over the world, and many celebrities are willingly switching to these fabrics. What is your opinion on this matter? Next, read about the material modacrylic and what it is needed for.

Types of polyurethane fabrics

Types of polyurethane fabrics

PU fabrics are divided into two groups:

- containing PU fibers;

- polyurethane coated materials.

The elastomer has found wide application in many industries. Several types of fabrics are used in the textile and haberdashery industry.

PU leather

PU leather is an environmentally friendly material used in making shoes, clothing, accessories, haberdashery, as well as for making furniture upholstery and car seat covers.

PU belongs to the class of non-woven fabrics, and is considered one of the best imitations of natural leather. Externally, the two types of material are very similar. Eco-leather is soft and pleasant to the touch. It has water-repellent properties and does not get wet. The difference with other types of leatherette is the absolute absence of a characteristic chemical odor and the ability to conduct air. In addition, PU is a durable and strong material.

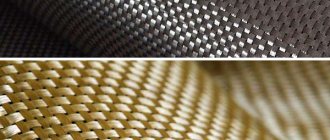

Polyurethane coated fabrics

Based on polyester (polyester) and nylon coated with polyurethane on the inside, fabrics with high protection against wind and moisture are produced - Oxford. The density of matter varies from 150 to 1600 Den.

Single- and double-sided PU coating is used for the manufacture of technical textiles. A special method of applying the component to the base allows you to give the fabric the properties of a membrane: remove steam and retain water on the outer surface.

Popular types of polyurethane materials

In the textile industry and clothing production, membrane materials are especially popular (Gore-Tex, Oxford, eVent, with PU nanocoating - Polartec Neoshell, The North Face Futurelight™, Outdoor Research AscentShell); elastane fibers in the composition of the fabrics.

Depending on the country of origin, stretch elastomer fibers have different trade names:

- Japan - espa, neolan;

- USA - lycra, vairin;

- Great Britain - spanzel;

- Italy is a warrior.

How PU fabric is produced

The production of the matter in question is a complex and labor-intensive process, consisting of several technological stages. Leather consists of several layers and the basis is usually cotton, knitted or any thin fabric, even non-woven materials.

- Material PU (PU) - what kind of fabric is it: description

Embossed leather

A thin layer of natural material is distributed onto it, obtained from scraps and defective areas of natural raw materials that have undergone special processing. This layer is impregnated with complex polymer mixtures to give it strength. The last coating - the third layer - is polyurethane, which gives the material texture.

You might be interested in everything you need to know about reflective fabrics

The technological process of applying polyurethane to a layer of natural leather occurs at a temperature of 130-160 degrees. The finished product does not lose the properties inherent in natural matter. Polyurethane is considered a synthetic material, but it allows you to dye PU leather in the most incredible colors, with patterns and prints for which consumers love it so much.

PU inner layer

This material acquires the following properties during processing:

- resistance to severe frosts;

- tolerates large mechanical loads;

- has super strength and elasticity, clothes made from it will tear only at the seams;

- has no synthetic smell.

The structure of this material is soft and pleasant to the touch. It is much lighter than genuine leather or leatherette.

Colors

Application

Products made from polyurethane fiber

Fabric with elastane fibers has a fairly wide range of applications. It is important to understand that this raw material is not used in its pure form; it is added to weaving fabrics in small quantities to improve properties. Sportswear, suits, blouses, skirts, dresses and many others are made from stretch fabrics. etc.

Coated fabrics are used in the manufacture of protective suits, tourism and sports equipment. Eco-leather is used for the production of clothing, shoes, and haberdashery.

PU is most often used in sewing the following models:

- jackets, raincoats, coats with water- and windproof properties;

- rubberized awnings;

- insulated trench coats and jackets;

- shoes (sole and formation of the surface of the model);

- upholstery and covers for furniture, car seats;

- wallets, bags, backpacks;

- cases for phones and tablets;

- gloves, belts.

The elastomer is widely used in the production of medical supplies (bandages, bandages, compression products).

Recommendations for care

Caring for eco-leather products requires dry periodic cleaning with a soft brush or sponge. After removing dust, it is recommended to treat the surface with a special spray.

Caring for materials containing PU is as follows:

- Wash at low temperature on a delicate cycle using soft gel detergents.

- Spinning and twisting is allowed only for elastic fabrics according to the manufacturer's recommendations.

- Ironing items made from PU fabrics is prohibited.

- For severe stains, dry cleaning is recommended.