The rapid development of the chemical industry has brought many new materials to the textile industry. Synthetic fibers are used to make various fabrics, including for technical purposes. The main advantage of using it is the cost of raw materials, in contrast to natural components that require special resources and additional labor costs.

Polypropylene, what kind of material it is and where it is used, is useful for every average person to know. It is important to note that this is one of the most common non-woven fabrics, cheap and popular. Belongs to the group of synthetic polymers.

Description

Polypropylene is a multifunctional material used in the production of technical products and as upholstery. Denoted by the abbreviation RR.

Technical fabric is dense to the touch, depending on the type it has different texture and density. One example is polypropylene fabric, which is used to make bags for packaging sugar. The material is moisture resistant and can withstand low temperatures down to -70°C. The upper limit of positive temperatures is indicated by + 60°C. At readings of + 160°C, the synthetic thread melts.

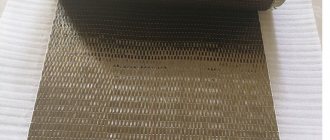

Non-woven fabrics are distinguished by a double-face structure and are produced by a special weave of threads (the differences are visible in the photo). The material is plain-dyed, plain.

Modifications of fibers intended for use in the textile industry have elasticity and low specific gravity (PP does not sink in water). The wear resistance and mechanical strength of these materials are average or lower. Textiles are resistant to chemicals, but vulnerable to UV rays.

Properties

Main characteristics of polypropylenes:

— density 900-930 kg/cub.m (lower for atactic polymer), the lowest for plastics;

— linear shrinkage of about 1.5-2.0 percent;

— crystallizing polymer with a degree of crystallinity up to 75 percent;

— glass transition temperature about -10 degrees C;

— melting point about 170 degrees C;

— destruction temperature is about 300 degrees C;

— MFI (melt flow index) according to GOST T = 230 degrees, load 2.16 kg, depending on the brand from 0.2 to 75 g/10 min;

— good economic indicators.

Chemical properties:

— good water resistance at temperatures below 130 degrees C;

— good resistance to aggressive chemicals, incl. acids (except the strongest) and alkalis;

— some brands are certified for contact with food;

— some brands are certified as medical.

Physical and mechanical characteristics:

— polypropylene homopolymer is brittle at subzero temperatures and is easily destroyed in the event of mechanical stress;

— copolymers with ethylene are more elastic, including in cold weather;

— weak thermal conductivity of about 0.15 W/(m*K);

— good transparency in the form of a thin film, for copolymers this is also true for thicker-walled products;

— heat resistance according to Vicat 95-1100С;

— good impact strength and wear resistance.

Performance properties:

— maximum temperature of use 120-140 degrees C;

- oxidation in the presence of oxygen at temperatures above 100 degrees C;

- a good electrical insulator.

Polypropylene has been proven to be environmentally friendly and safe for humans and living organisms due to its complete chemical inertness. In view of this, polypropylenes are widely used in the production of products in contact with food and water.

Types and brand assortment

Each previously described type of polymer is divided into numerous grades and groups according to processing methods: extrusion, blowing, injection, etc. In addition, a huge range of compounds and filled grades of polypropylene is produced. Its main types and the most common brands of PP and its copolymers are presented below.

- Propylene homopolymer (PP homopolymer, PP HO, PPHP, PPH), isotactic polypropylene;

- PP block copolymer (PP block-copolymer, PP impact copolymer, PP CO, PPCP);

- Polypropylene stat or random copolymer (PP random copolymer);

- Other less commonly used types of pure polymer: atactic, syndiotactic, metallocene, cross-linked, etc.

- Filled brands of polypropylene: glass-filled, mineral-filled, WPC, others.

- Thermoplastic elastomers or elastomers based on PP (mixed, vulcanized, “reactor”).

In addition to its relationship to one type or another, any grade of polymer includes data on its fluidity, which determines its applicability to processing methods. For example, “Balen 01003” means that the fluidity index of the brand is 0.3 g/10 min, which determines the use of the brand in extrusion. They say about such polypropylene that it is a “pipe grade”. A similar PP of the same type has a MFI of about 27 g/10 min, which clearly indicates the possibility of use for injection molding. Foreign and modern domestic brands of polypropylenes do not contain data on fluidity in their names, however, the value of MFR is strictly regulated for each of them.

Production of PP fabric

Polypropylene thread is made by extruding or blow molding molten raw materials (at a temperature of 100°C), followed by cooling in an air chamber and winding onto bobbins. At the final stage, the fibers are cut according to the specified parameters.

During the production process, 2 types of synthetic threads are obtained: filament (twisted from ultra-fine fibers) and staple. PP fabric is made by gluing or pressing (passing through heated calender rolls). In some cases, continuous length fibers are used (for example, in the manufacture of spandob).

PP in its pure form is rarely used for the manufacture of upholstery fabrics, car covers and carpets. Other synthetic components (polyester, polyamide, etc.) are added to the polymer fibers.

Polypropylene recycling

PP waste is usually made into pellets, which are then reused in factories to make plastic items.

Recycled polypropylene is cheaper than “primary” polypropylene, but is practically not inferior to it in terms of the most important properties. This makes it profitable for production, and as a result, in modern industry there are no objects that are made entirely from only primary or only from secondary raw materials.

The recycling process includes several stages:

- Sorting and thorough cleaning of waste.

- Splitting up.

- Temperature effects (sintering), granulation.

The recycled materials can then be subjected to any type of further processing along with the “virgin” plastic.

Today, the following methods for manufacturing products using recycled PP are mainly used:

- Injection molding: heated raw materials are placed in a mold, where they cool down within specified parameters under the influence of increased pressure. The processing temperature of polypropylene is from 200 to 260 degrees Celsius. This is how household and medical goods, machine parts, containers, fittings, etc. are obtained.

- Extrusion: here the shape of the future product is given using the forming head of an extruder, through which the heated plastic mass is extruded. The shape is maintained by rapid cooling in a special container or air flow. Fibers, threads, dishes, pipes, textiles, different types of bags, films, sleeves from recycled PP materials are obtained using this technology.

- Blow molding (blow extrusion): used to produce bottles.

- Foaming: gaseous substances are added to the original raw material to obtain products with a loose, porous structure. The resulting material is used to make packaging, containers, insulating materials, etc.

- Rotational molding: Raw materials are heated and placed in a rotating mold to produce hollow objects such as canisters, tanks, etc.

Recycling polypropylene is an example of waste-free production. Recycled PP, obtained using the most advanced technologies, is a high quality product, which is then widely used in industry.

Composition and formula of the material

Polypropylene fiber is obtained from petroleum products by catalytic or thermal cracking. Granules of the substance are produced by the polymerization of propylene. The monomer is extracted from crude oil in a gaseous state, then subjected to a chain polymerization process in the presence of a catalyst (titanium-chloro-aluminum). The technology provides for certain temperature conditions (94 – 96°C) and a pressure of 30 atm.

After 8 hours, polymerization results in a solid plastic material in the form of granules. Using high-temperature exposure, propylene resin is obtained, mixed with fillers, dyes, plasticizers and stabilizers. After cooling, the resulting raw materials are used to produce granules or ingots.

The chemical formula of polypropylene looks like this: (C₃H₆)n or (nCH2=CH(CH3) → [-CH2-CH(CH3)-]n). The most famous enterprises producing RR are Borealis, SIBUR, ExxonMobil Chemical, LyondellBasell, SABIC, etc.

Description and production of polypropylene

The industrial production of polypropylene was the first to be organized by Italy at the end of 1957. Currently, large industrial capacities have been commissioned in many countries, including Russia.

1. Raw materials and production of polypropylene Propylene is isolated from cracking gases of oil or petroleum products. By creating the necessary cracking conditions, namely: pressure, temperature, process duration and using the required catalyst, it is possible to direct the destruction of hydrocarbons included in the oil towards the formation of predominantly propylene and ethylene. Propylene is separated from the mixture and purified by deep cooling. Propylene is a colorless, flammable gas with a faint odor. Its molecular weight is 42.078, melting point - 185.25 ° C, boiling point - 47.70 ° C, auto-ignition temperature - 455 ° C, explosive limits in a mixture with air - 2.0-11.1% (volume). In petroleum cracking gases it is contained in an amount of 5-18% (by weight). Propylene is very reactive and easily attaches various compounds to double bonds.

In industry, polypropylene is produced by polymerization of propylene in a solvent (gasoline, hectane, propane) at a pressure of 1-4 MPa (depending on the solvent used). The reaction occurs at 70°C in the presence of the catalytic complex AiRg + TiCI3. The maximum activity of the catalyst is at the molar ratio AiRg: TiCl3>3: 2. The degree of crystallinity of polypropylene depends on the size of the catalyst particles. The activity of the most commonly used catalytic complex decreases in the presence of atmospheric oxygen or traces of moisture, so polymerization is carried out in a nitrogen atmosphere using thoroughly dried solvent and propylene. The catalyst is prepared in 1 m2 apparatus. The catalyst components are dosed by pumps and enter the polymerizer in a given ratio, where the monomer is simultaneously supplied. The heat of polymerization is removed by cooling the reactor walls or a cooling coil. The resulting polymer suspension flows by gravity into a collection containing alcohol (higher) to stop polymerization and decompose the catalyst. Then the polymer is filtered and residual solvent is removed with hot water vapor. Due to the low density of polypropylene, it floats to the surface of the water. After the polypropylene is separated from the water and dried, it is subjected to final drying under a nitrogen stream. A method for the production of isotactic polypropylene in the presence of chromium oxide catalysts on aluminosilicate. Much attention is paid to further improvement of the polymerization process. Thus, in England, a method was proposed for the polymerization of polypropylene in liquefied low-boiling hydrocarbons (pure propylene, propane or butane). This simplifies the purification of the original hydrocarbons, removes the heat of polymerization due to the heat of evaporation of the solvent, and makes it possible to achieve high polymerization rates. Work is underway to reduce the amount of circulating solvents during the polymerization process. For this purpose, it is proposed to carry out the polymerization of gaseous polypropylene under the action of complex catalysts: titanium trichloride + triethyl aluminum applied to particles of powdered polymer or at temperatures above the melting point of polypropylene, when the resulting polymer flows off the catalyst carrier. 2. Properties and applications of polypropylene Depending on the conditions of the propylene polymerization process, polymers with different molecular structures are obtained, which determines their physical and mechanical properties. Isotactic and syndiotactic molecular structures can be characterized by varying degrees of perfection of spatial regularity. Stereoisomers of polypropylene differ significantly in mechanical, physical and chemical properties. Atactic polypropylene is a rubber-like material with high fluidity, a melting point of about 80°C, a density of 850 kg/m3, and good solubility in diethyl ether. Isotactic polypropylene in its properties differs favorably from atactic polypropylene, namely: it has a high modulus of elasticity, a higher density - 910 kg/m3, a high melting point - 165-170 ° C and better resistance to chemical reagents. Stereoblock polymer polypropylene, when examined by X-rays, exhibits a certain crystallinity, which cannot be as complete as that of purely isotactic fractions, since the atactic regions cause disruption in the crystal lattice. Polypropylene has valuable properties for its versatile use in construction equipment. The main influence on the properties of polypropylene and construction products made from it (pipes, plates, films) is exerted by the molecular and supramolecular structure in the polymer chain. Polypropylene is characterized by a very complex molecular structure, since in addition to the chemical composition of the monomer, average molecular weight and molecular distribution, its structure is greatly influenced by the spatial arrangement of side groups relative to the main chain. In technical terms, isotactic polypropylene is the most important and promising. Depending on the type and ratio of stereoisomers present, the properties of polypropylene vary over a wide range. The ability of their processing by one or another method depends on the molecular structure of polymers, which in turn largely determines the properties of the finished products. 3. Brief description of the influence of the main structural parameters on the properties of polypropylene. The molecular weight of polypropylene varies widely - from 35,000 to 150,000. Polymers with a molecular weight below 35,000 are more brittle. Various physical and mechanical properties of the polymer depend on the molecular weight in different ways. Thus, under mechanical loads associated with small deformations or low speeds, with a change in molecular weight (for polypropylene with low molecular weight), such polymer properties as yield strength and elastic modulus change slightly. The mechanical properties of polypropylene, associated with large deformations, strongly depend on the molecular weight. Thus, tensile strength, elongation at break, and impact strength decrease with decreasing molecular weight. These properties are also affected by polydispersity. The latter is explained by the fact that at high deformations the atactic amorphous regions of the polymer begin to play the leading role. The more ends of macromolecular chains are in these areas, and their concentration naturally increases with decreasing length of macromolecules, the faster their mutual weakening, shift or removal from each other occurs. This is because they are connected only by intermolecular bonds, which are much weaker than the chemical chain bonds or cohesive forces acting in the crystalline regions. The mechanical properties of polypropylene depend on its average molecular weight, polydispersity and atactic phase content. The latter is determined by weighing the polymer residue after extraction with boiling n-heptane, in which the atactic polymer dissolves. With a decrease in the isotactic phase, and therefore with an increase in the atactic phase, the mechanical properties of polypropylene deteriorate. Molecular weight is usually determined by viscosity in o-xylene solutions at 120°C. The melt index is used as an indicator of molecular weight. The lower it is, the higher the molecular weight of the polymer. Typically, polypropylene has a melt index of 0.2–5.0 g/10 min. With increasing molecular weight, the mechanical properties of polypropylene improve (yield strength and tensile strength). The impact strength of isotactic polypropylene cannot be determined at 20°C, since this polymer does not degrade under normal temperature conditions. At lower temperatures, for example, it has the following values: at -20°C, impact strength is 20-30 kJ/m2 and at -80°C 13-17 kJ/m2.

4. Thermophysical properties.

Isotactic polypropylene differs sharply from atactic polypropylene, not only in solid form, but also in the melt. The specific heat capacity of isotactic polypropylene increases linearly at temperatures up to 100°C, and at higher temperatures the specific heat capacity increases sharply, passes through a steep maximum to the melting point region (166°C), and then drops to a relatively constant value of approximately 2.72 kJ/kg °C (for melt). The temperature dependence curve of specific heat capacity for atactic polypropylene has a more complex shape.

Due to the heterogeneity of molecules and different crystallite sizes, the melting point of polypropylene varies from 160 to 175°C. In the absence of mechanical impact, polypropylene products retain their shape at a temperature of 150°. The heat capacity of polypropylene is greatly influenced by the presence of impurities and contact with certain metals, such as copper or its alloys. Therefore, when installing polypropylene pipelines for hot water supply, you should not use fittings containing copper elements. The chemical resistance of polypropylene due to its paraffin structure is very high. At normal temperatures, isotactic polypropylene resists organic solvents very well. However, any violation of the correctness of the chain structure, manifested in a decrease in the degree of crystallinity of polypropylene, causes a decrease in its resistance to solvents. Due to the poor solubility of polypropylene, the possibility of gluing polypropylene parts and obtaining films and protective coatings by casting and applying solutions is excluded. To characterize the chemical resistance of various polymers, including polypropylene, there are special tables that indicate the resistance of the polymer to reagents (solvents, acids, alkalis, salts) at various concentrations and temperatures. Mineral and vegetable oils, even with prolonged exposure, are adsorbed by polypropylene in negligible quantities. All types of polypropylene do not absorb water, except for a negligible adsorption surface. The weather resistance of polypropylene under conditions of exposure to sunlight and elevated temperatures should be considered insufficient, since under these conditions polypropylene undergoes destruction with a significant decrease in physical and mechanical properties. In order to prevent the destruction of polypropylene during its heat treatment (heating and oxidation) and during the operation of products (films, pipes), it is necessary to introduce stabilizers into polypropylene. Unstabilized polypropylene changes especially strongly when exposed to direct sunlight, as a result of which the polymer and products made from it become brittle. Ultraviolet rays have a strong oxidizing effect, and the introduction of antioxidants into the polymer produces an inhibitory effect only for a short time. Ultraviolet rays with a long wavelength (300-370 microns) act most effectively on polypropylene, as a result of which the polymer loses its mechanical strength. The destruction of polypropylene is greatly influenced by temperature—increasing it for every 10°C almost doubles the rate of destruction. A good stabilizer for polypropylene is soot - introducing it to 2% significantly reduces destruction: To reduce the oxidative destruction of polypropylene, you can also use di(oxyfinyl)-sulfite in an amount of 1-2%. The brittleness time at 140 °C (the time after which the polypropylene film breaks when it is completely folded) is 24–40 days. Polypropylene with the introduction of stabilizers into it is resistant to oxidation and destruction even when heated to 300°C for several hours. Polypropylene has not yet found widespread use in construction technology, but should be classified as a very promising material both due to its high technical properties and due to the variety of methods for its technological processing into products (extrusion, injection molding, blowing, pressing and vacuum forming) . The disadvantages of polypropylene as a raw material for the manufacture of building materials and products include its poor adhesion. Only when using chloroprene adhesives are acceptable results achieved, although the strength of the gluing site is inferior to the strength of the material itself. Welding of polypropylene products and materials gives good results and is carried out with a hot stream of air or nitrogen heated to 220°C. To increase the impact strength of building products, polypropylene with the required melt index should be used and combined with synthetic rubbers, polyisobutylene and butyl rubber. The following types of products for construction equipment are made from polypropylene: pipes, films, sheets, ventilation grilles and sanitary equipment. For the production of pipes by extrusion, polypropylenes with a high and medium degree of crystallinity, the melt index of which lies in the range from 0.5 to 3.0, are most suitable. Polypropylene pipes are produced with a diameter of 25-150 mm. They are more durable than polyethylene pipes, much more heat-resistant, but are inferior to polyethylene pipes in frost resistance. For the manufacture of polypropylene pipes, the centrifugal casting method can also be used. Polypropylene pipes are used for hot water supply and for transporting “aggressive” liquids. Polypropylene films are produced by stretch blown extrusion. They are very transparent and durable, have good weldability, low water, vapor and gas permeability. They are used for various types of insulation of structures. Propylene sheets are made up to 0.5 mm thick by extrusion or pressing. Used for the manufacture of various containers in sanitary equipment, fans, grilles, etc. Polypropylene can be used for protective coating of metal by spraying or immersion. Amorphous polypropylene is used for the production of construction adhesives, putties, sealing mastics and adhesive films.

Characteristics

To understand the question: PP material, what is it, it is necessary to study the technical characteristics and description of the main properties.

Properties | Indicators |

| Raw material type | Synthetic chemical |

| Weaving method | Non-woven fabric obtained by gluing raw materials (fibers), special weave |

| Density of PP, g/cm3 | 0,90 – 0,91 |

| Water resistance | good |

| Hygroscopicity,% | 1 – 5 |

| Moisture absorption rate | Below average |

| Breathability | Small |

| Vapor permeability | Low |

| Electrification | Noticeable |

Open to see the entire table

| Side | Double-faced canvases |

| Coloring methods | Plain painted plain |

| Manufacturer | Russia, China |

| Standardization | GOST 26996 – 86 |

| Price | Low |

Physico-chemical basis of polypropylene

Polypropylene is directly produced from propylene gas by polymerization. This process occurs in the presence of metallocene catalysts. In its initial state, polypropylene is a white substance.

The beginning of active production of this polymer is associated with the use of Ziegler and Natta catalyst units, when in 1957 it became possible to obtain isotactic polypropylene. It is obtained at a temperature of 80 ° C under a pressure of 10 atm.

There are several types of polypropylene used in the production of final products:

- Isotactic.

- Atactic.

- Syndiotactic.

Isotactic propylene has become the most popular in production.

This happened due to the peculiarities of this species, where the side CH3 groups, which are located unusually in relation to the main chain, received a special position. This structure of polypropylene determined a number of its main qualities: high crystallinity and strength, hardness, and the ability to retain shape at high temperatures.

Some finished products have successfully used a combination of several different types of polypropylene. For example, by adding atactic polypropylene to the composition, the manufactured part can be endowed with flexibility and softness.

The basic physical and chemical properties of polypropylene can be presented in the form of a table:

| No. | Property of polypropylene | Indicator value |

| 1 | Density, g/cm3 | 0,90-0,92 |

| 2 | Tensile strength, kg/cm2 | 260-400 |

| 3 | Tensile elongation at break, % | 200-700 |

| 4 | Melting point, °C | About 170 |

| 5 | Temperature at which the material becomes brittle, °C | -10…-20 |

| 6 | Dielectric constant, at 106 Hz | 2,2 |

| 7 | Electrical resistivity, Ohm | 1016 |

| 8 | Coefficient of volumetric expansion when heated | 0.00033 at 20 °C |

| 9 | Frost resistance, °C | -20…-25 |

| 10 | Specific heat capacity, cal/(g×deg) | 0,4…0,5 |

Thus, if we analyze the tabular indicators, polypropylene manifests itself as a stable neutral material. It does not significantly change its properties at positive temperatures. At the same time, it remains a neutral substance in relation to electric current, excessive air humidity and high temperatures.

A special feature of propylene is its neutrality with respect to many chemicals. Thus, this material withstands the effects of acidic and alkaline solutions, alcohols, as well as many inorganic compounds, including salt solutions. An exception may be interaction with some solvents. Thus, polypropylene, when placed in benzene or ether, is capable of swelling and subsequent dissolution. It is noteworthy that in the case of timely removal of the source of swelling, for example, benzene, polypropylene completely restores its structure while maintaining its original properties.

Concentrated acids - sulfuric, nitric, and chlorosulfanic - act most destructively on polypropylene.

Among the disadvantages of polypropylene, several characteristic features can be noted:

- low frost resistance. The brittleness that occurs under the influence of negative temperatures, however, is eliminated by introducing ethylene units into the material. In practice, materials such as ethylene propylene rubber and butyl rubber are also actively used;

- sensitivity to external light exposure, as well as to interaction with oxygen. This deficiency manifests itself in the form of an ongoing decomposition process, external clouding of the material, loss of shine, and even the appearance of small cracks. In order to prevent active aging of the material, manufacturers are forced to somewhat smooth out this effect by introducing special polymer stabilizer additives into the composition.

Is polypropylene harmful?

The use of propylene in various applications is due to the safety of the material. PP, when handled, maintained and disposed of correctly, does not pose a danger to human health and the environment.

PP is used to produce hygiene and medical supplies and plastic utensils. Allergic reactions caused by polypropylene sheets are rare.

Expert opinion

Alyona

Fabric expert and technologist Alena Khlebnikova is ready to answer your questions.

Write to us

All products are marked PP. In some cases, the manufacturer indicates the maximum permissible temperatures under the abbreviation. Usually it does not exceed 60°C. If the rules are followed, polypropylene products are completely safe for both people and the environment.

When the above parameter is heated and during the production of fibers, the raw material releases harmful substances: phenols, volatile fractions of formaldehyde, heavy metal salts, etc. Therefore, special requirements are placed on production conditions. You cannot heat food in dishes made of light plastic and use PP food containers for long-term storage of food.

General properties of polypropylene

According to DIN 8078, part 3, the following types of polypropylene are distinguished: Type 1: PP-H (homopolymer) Type 2: PP-B (block copolymer) Type 3: PP-R (unstructured polymer)

As a result of copolymerization with With ethylene, type 2 and type 3 polypropylene acquired special properties that made it possible to improve the manufacturability of the product manufacturing process (for example, to achieve lower shrinkage), as well as higher hardness compared to PP-H.

Physiologically non-toxic.

Due to its composition, polypropylene material is approved for use in the food industry (In accordance with QNORM B 5014, Part 1, BGA, KTW Guidelines).

AGRU pipes, sheets and round bars have been produced from PP-H since the mid-seventies. Fittings have been produced from PP-R since the late seventies. Both types have been stabilized against high temperatures and are the best materials for the production of pressure piping systems.

Compared to other thermoplastics such as PE-HD and PVC, PP shows thermal stability up to 100°C (short-term up to 120°C for lower pressure systems).

PP shows good impact resistance compared to PVC.

Impact strength depends on temperature, increasing as the temperature increases and decreasing as the temperature decreases.

How PVC differs from polypropylene

Non-woven polypropylene is widely used for various household needs. The material is used in construction, medicine, and carpet production. It is used as an additive in concrete mixtures and for the manufacture of reinforcing mesh. Used as roofing roll material and insulator (for braiding cable elements).

PVC is considered an alternative inexpensive option. Thanks to additional components (plasticizers, stabilizers, fillers), polypropylene has superior properties to polyvinyl chloride: it has less elongation when heated and compressibility when cooled, demonstrates increased density and resistance to mechanical damage.

Kinds

Manufacturers of synthetic nonwoven fabric offer consumers several types of PP:

- Transparent. Strong, durable material produced without coloring additives.

- Color. The disadvantage of such a canvas is considered to be the instability of color when exposed to sunlight (fading).

- Reinforced. Used in construction. Increases strength and has elasticity.

- Spunslace is a material with a smooth surface, a type of woven polypropylene.

- Thermobond and spunbond are used for the top layer of hygiene items (pads, diapers), in the production of wet wipes, shoe covers, and tablecloths.

To increase moisture resistance, the fabric is treated with a special method. Laminated material is used in the production of protective coatings and packaging products.

All types of non-woven and woven PP are recyclable. The main disadvantage of polypropylene is its inability to decompose under natural conditions.

Application

Since the middle of the last century, polypropylene fibers began to be used in the manufacture of fabrics for sewing sportswear and thermal underwear. In extreme conditions during fires and explosions, the fabric began to melt and contributed to life-threatening burns. Therefore, the innovative idea had to be abandoned. Currently, PP thermal underwear is rarely used. It is not recommended to wear it for a long time.

The material is used in various fields and the following things are produced from it:

- carpets, mats, rugs;

- curtains;

- decorative items;

- production of thermal underwear;

- building materials: panels, floor coverings, flexible roofing, geotextiles (sheets and fabrics for cutting);

- containers and bags for the food industry and trade;

- packaging materials;

- car seat covers;

- tablecloths;

- as components for the production of mattresses;

- upholstery for sofas;

- automobile filters;

- disposable tableware;

- items for hygienic and medical purposes. For example, a diaper for children consists of several layers of different types of PP.

Areas of application of polypropylene

Polypropylene is widely used to ensure effective economic development and increase the competitiveness of products. This happens due to:

- reducing material consumption,

- replacement of expensive materials,

- creating a new generation of technology,

- formation of advanced technologies for materials processing.

Polypropylene can be used to produce many products, including mixed thermoplastic elastomers and high-modulus, high-strength plastics. Thanks to its environmental friendliness, ease of processing and disposal, polypropylene is displacing polyvinyl chloride, impact-resistant polystyrene and ABS plastics from the global plastics market.

Polypropylene is actively used in all dominant sectors of the economy:

- automotive industry,

- mechanical engineering,

- electronics,

- electrical engineering,

- instrument making,

- transport,

- construction, etc.

It is sometimes called the “king” of plastics. Polypropylene also has a strong position in the production of polymer fibers and threads. Low price and ease of disposal allow it to displace other materials from production. Polypropylene is used in the manufacture of household items (carpets, rugs), hygiene (disposable diapers) and medical products.

Currently, this material cannot be called the most popular polymer - polyethylene and polyvinyl chloride are leading the market. At the same time, in terms of production growth rates, polypropylene is unrivaled. It should also be taken into account that even in the 21st century, not all the scientific and technical potential of the polymer has been realized.

Package

Polypropylene films are one of the most popular packaging material options in the world. Their characteristics are close to polyethylene films. At the same time, in many respects, polypropylene films are superior to products made from other polymers. They are highly resistant to heat and chemicals. Polypropylene films can be sterilized at temperatures above 100°C, increasing their value in the pharmaceutical and food industries.

The products are also characterized by transparency, flexibility, non-toxicity and easy weldability. Another reason for the popularity in the packaging market was such an innovation as film orientation. Materials oriented in one or two mutually perpendicular directions have been produced relatively recently, but they have already proven themselves in the flexible packaging market.

Thanks to the orientation of the film, its strength, rigidity, transparency and moisture-proofing properties increase. The transparency of such material exceeds the transparency of non-oriented products by at least 4 times.

Custom polypropylene bags have competitive advantages over plastic bags. Such packaging is more transparent, durable, environmentally friendly and presentable in appearance.

Polypropylene is gradually replacing polyethylene terephthalate and other plastics in the production of bottles and bottle caps. You can increasingly see polypropylene products on store shelves. Instead of standard label paper, propylene film is used.

The material is also used in the production of such types of packaging as packaging and containers. Due to its high strength, polypropylene replaces polystyrene, and due to its rigidity and glossiness, it replaces many types of polyethylene. High resistance to chemicals allows the use of polypropylene for cladding containers in which aggressive liquid substances are stored and transported.

Fibers

Polypropylene has significant advantages over other polymers in the field of fiber production. Such products have a low price. More fiber can be obtained from 1 kg of polypropylene than from 1 kg of other polymers. At the same time, the products are distinguished by high strength and impeccable elastic properties.

Polypropylene also has high heat resistance. Only sensitivity to damaging ultraviolet radiation has slowed the wider adoption of polypropylene fibers in the textile industry.

Electronics and electrical engineering

From polypropylene they create:

- coils,

- TV cases,

- insulating shells,

- lamp sockets,

- parts of switches, radios, telephones, etc.

Currently, the material is used quite rarely as an insulating material. In this area, PVC still remains practically no alternative. In the production of foam insulation for wires, polypropylene successfully competes with polyethylene.

Medicine

The most sought-after quality of a material in medicine is resistance to high temperatures. Thanks to this, products made of polypropylene can be subjected to hot sterilization. Inhalers and disposable syringes are made from it. When compared with polyethylene and polystyrene, the material occupies a leading position in this area. The syringes are also packaged in film. Polypropylene is used for its manufacture.