Structure and manufacturing features

Asbestos fabric is a fabric made from interwoven asbestos threads, to which a binder of viscose, lavsan (polyester) or cotton fiber is added.

The content of binder fibers can range from 5 to 18%; the duration of use of asbestos fabric depends on their type. If natural cotton fiber was used for its manufacture, the warranty period will be up to 5 years; when using synthetic polyester fiber, its duration increases by 2 times. Only chrysotile asbestos is used in production - it is a safe material that does not have carcinogenic properties. It is a layered material made from bundles of thin fibers. They have very high resistance to tearing - in this indicator they can be compared with steel. This asbestos sheet does not cause the development of cancerous tumors, so it can be safely used by humans.

Mining and production

The largest deposits of asbestos are located in Canada, South Africa and Russia; it is also mined in China, Brazil, the USA, Japan and some European countries. The mineral is mined by open-pit mining, after which it is enriched at specialized chemical plants to produce chrysotile asbestos.

Chrysotile is divided into eight grades. The determining criterion is the length of the fibers. The first three varieties are characterized by long fibers and are textile. The latest varieties, on the contrary, have short fibers and are used in construction. Chrysotile can have different textures and is divided into hard, semi-hard and soft. In hard chrysotile needles predominate, in soft chrysotile there are fluffy fibers.

Currently, mineral reserves are estimated at 200 - 250 million tons. Despite the emergence of new synthetic materials, it is still widely used in a wide variety of industries and construction.

Basic properties of asbestos fabric

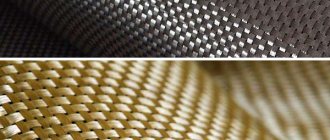

Asbestos sheet is produced in rolls, the weight of which should not exceed 80 kg. The width of the fabric can be standard or non-standard, the choice depends on the customer's requirements. The material has a natural white or yellowish-brown color with a rough texture. Asbestos fabric has the following properties and features:

- Fire resistance, thermal insulation properties. It was they who provided asbestos fabric with the widest use in industry: it is used in the manufacture of fire-resistant materials and insulators.

- Flexibility. The material is an easily bendable fabric; it does not crack or tear. This is a fabric that, if necessary, can be folded or rolled into rolls; it is convenient for transportation over long distances.

- Resistance to biological influences. The material is not destroyed by fungus, mold or microorganisms. This ensures long-term operation of asbestos fabrics even in conditions of frequent contact with high humidity.

- Resistant to chemicals. The material does not collapse upon contact with weak acidic and alkaline solutions. This increases the life of its use in aggressive environments; asbestos fabric can be used in boiler rooms and for insulating various industrial equipment.

- Minimal electrical conductivity. Due to its dielectric properties, asbestos sheet is used as an insulator. It practically does not allow electric current to pass through.

- Low sound conductivity. Fabric with asbestos fibers can be used as a sound insulator, as it has the ability to block the propagation of sounds.

- This set of characteristics has ensured widespread use in various industries: asbestos fabric is in great demand as a fireproof, electrical, heat, and sound insulating material.

Purpose

The scope of application of asbestos fabric is extremely wide. It is used as thermal insulation. Special fire-resistant clothing and industrial equipment products are made from it . It is mainly used where it is necessary to protect people or equipment from exposure to high temperatures. Also, asbestos sheet can be used to increase the wear resistance of other materials .

Main brands of asbestos fabric: properties and features

The production of asbestos fabric is carried out in accordance with GOST 6102-94. Depending on the percentage of mineral fibers in the composition, various brands are distinguished, there are several dozen in total. Brands are classified, among other things, by the binder used in the composition, on which the strength and durability of the finished material depends. The most popular varieties:

- AT-1S. This is an asbestos fabric made from natural cotton fibers; it can be used to make rubberized fabric. It contains up to 85% mineral components; the material can withstand heating up to 400 degrees Celsius.

- AT-2 and AT-3. These brands are distinguished by a lower concentration of mineral fiber, it reaches 81%. The material can be used in the manufacture of asbestos textile laminates; various types of insulation are made from it.

- AT-4 and AT-5. Brass wire is used as a binder for this type of fabric, rather than textile fiber. As a result, the material acquires very high strength and tear resistance, which makes it possible to use it in extreme conditions.

- AT-6. The concentration of mineral fiber in the fabric of this brand reaches 95%; the binder is cotton fiber.

- AT-7, AT-8 and AT-9. These brands are resistant to extreme heat and can withstand temperatures up to 450 degrees. The composition contains up to 90% mineral fiber.

AST. This material is based on asbestos threads and fiberglass; they are twisted in a special way and intertwined with each other. The resulting fabric is used in the manufacture of heat-resistant clothing.

Only the basic brands of asbestos fabric that are most widely used are listed. Based on them, special materials are produced that have improved performance characteristics.

Why and where is asbestos fabric used?

The scope of application of the material covers:

- production of asbestos textiles (AT 1, AT 2);

- production of sealed rubberized fabrics;

- sewing heat-resistant workwear and thermal protective coatings;

- production of industrial equipment elements (friction discs, spacer rings, cuffs and many other products).

The material, in which glass fiber is the binder, has specific technical characteristics and is used as thermal insulation and cushioning. Types of fabric using cotton or viscose fiber serve as raw materials for the production of layered materials impregnated with resins or varnishes (asbestos textiles) and industrial equipment products. They also produce options where metal wire and aluminum foil are introduced into the fabric structure.

Rules for working with asbestos fabric

When working with asbestos fabric, microscopic dust containing asbestos particles is released into the air. Its permissible concentration should not exceed 2 mg/m3 for a single contact or 1 mg/m3 during a work shift. In order to prevent the negative impact of asbestos dust on the health of working personnel, they must be provided with personal protective equipment and comply with established standards for ventilation of production premises.

The use of chrysalite asbestos, which does not have a fibrinogenic effect, can reduce the carcinogenicity of production. This material is gradually replacing ordinary asbestos, which can pose a threat to human health.

The manufactured material is packaged in plastic bags or polymer film, and the rolls are secured with twine. Since asbestos is not a flammable material, it has a low fire hazard. Proper handling of asbestos fabric and compliance with storage standards extends its useful life. The material is stored in dry, ventilated areas in sealed containers. During transportation, asbestos fabric is moistened with water to prevent the spread of large amounts of dust.

Environmental characteristics of asbestos fabrics

Asbestos fabric has good quality assurance and meets the rules and regulations set by the country.

Asbestos fabric fibers can easily split into smaller ones. The body is directly affected by asbestos dust, which enters it through inhalation. It can cause various diseases, such as lung cancer or malignant tumors of the abdominal cavity and pleura. Therefore, it is very important to take precautions when working with fabrics, since it is impossible to find a safer replacement for asbestos. Only this material has such characteristics. But its more expensive analogues still do not match its mechanical properties.

In order to reduce the risk of inhaling asbestos dust, products made from this material can be painted or covered with film, and those things that are not treated with protective materials should not be placed in places with good air exchange.

Directions for using asbestos fabric

Thanks to its advantageous set of characteristics, asbestos fabric is widely used in various industries. It is used in the following areas:

- Manufacturing of heat-resistant suits used by firefighters and rescuers. They are made from fabric that can withstand very high temperatures and will not catch fire when in contact with an open flame.

- Production of asbestos textiles. This is a durable layered material with dielectric properties and high mechanical strength. Layers of asbestos fabric are impregnated with special resins and connected to each other using hot pressing.

- Production of thermal insulation boards. Asbestos fabric helps improve the energy efficiency of various buildings and structures, as well as slow down the spread of noise.

- Production of materials used in fire extinguishing. Refractory material is also used in the construction of furnaces and installation of boiler equipment.

This is not a complete list of areas of use. Asbestos fabric is used in industry, construction, sewing workwear, making insulating gaskets and many other products. The use of environmentally friendly material without carcinogenic hazard further expands the possibilities of application in the manufacture of various types of clothing and the production of insulators for buildings and structures.

The catalog contains a wide range of types of asbestos fabric with different characteristics; our consultants will help you select the appropriate type of product and place an order for a wholesale or retail batch at a favorable price. High quality products and compliance with standards are guaranteed.

Scope of application of asbestos fabric

Asbestos is often added to cement to increase the strength of the concrete composition. Due to its resistance to high temperatures, the material is used in the production of durable heat-resistant pipes and sheet materials, pebbles.

In industry, to increase the wear resistance of parts of equipment or individual elements, a fine fraction of asbestos, ground asbestos, is used.

The use of asbestos in manufacturing is common as a natural filtration material. Since asbestos is a dielectric, it is one of the fillers in plastics and electrical insulators.

So, briefly about asbestos fabric

Asbestos fabric (asbestos fabric) is a fabric made of interwoven asbestos threads containing from 5 to 18% binder fiber (viscose, cotton, lavsan). It is used as a heat-resistant heat-insulating and cushioning material. Asbestos fabric is used for the manufacture of rubberized fabrics, asbestos textiles, industrial equipment products, for sewing heat-protective clothing and heat-protective coatings. Asbestos fabric is supplied in rolls 1550 mm wide and weighing up to 80 kg. Working environment temperature from +130 to +500 degrees Celsius.

Advantages of asbestos fabric:

- Durability.

- Strength.

- Wear resistance.

- Excellent thermal insulation properties.

Manufacturing of asbestos fabric

The material for making asbestos fabric is asbestos threads intertwined with each other and fiberglass.

The threads also contain binder fibers made of cotton or viscose - no more than 20%.

Asbestos fabrics of all brands are produced using special industrial looms that weave asbestos thread according to specified parameters.