Almost all modern clothing is either entirely or partially made from synthetic materials.

If previously the word “synthetics” was associated with low quality, now artificial fabrics have reached a new level.

One of the most popular materials is polyester. Absolutely every person has clothes made from this fabric in their wardrobe, and in recent years, polyester has also stepped up to a new level, emerging as a promising industry for recycling plastic waste .

Let's talk in detail about polyester and figure it out:

- what kind of fabric is this, what are its properties;

- pros and cons of the material;

- the advantages of clothing and other things made of polyester;

- how it is used as a filler and insulation;

- what is made from it, what products are made;

- how they are made from recycled materials, and whether the quality and characteristics suffer;

- is it harmful to health?

Characteristics and properties of fabric

This is a woven material consisting of synthetic fibers. It is also known by other names:

- lavsan;

- polyethylene terephthalate;

- PAT.

Every major textile company tries to patent the slightest changes, assigning more and more new trade names.

But the essence remains the same, polyester (polyethylene terephthalate) is used as a base . Only the methods of forming the fiber and weaving the threads differ.

Types of material and description

Types of threads and fibers:

- Hollow structure fiber . It has voids inside, due to which it has exceptional thermal insulation properties.

- Staple fiber . It is short in length, only about 50 mm. It is used for the production of fillers and insulation materials.

- Structured (filament) thread . Used for finishing products. The stretchability of the threads is satisfactory, they cling firmly to each other.

- Monofilament . It has practically unlimited areas of application. Depending on the density of the weave, it can be used to make the finest chiffon and dense bologna.

The modern weaving industry combines lavsan threads with fibers of natural and artificial origin. The range of fabrics based on the mixture is extremely wide. As you can see in the photo, products made from the same material can look completely different.

Naturally, the characteristics of each material are unique. But there are still some common properties that distinguish polyester fibers:

| Property | Meaning |

| Density | 1.38-1.4 g/cm3 |

| Water absorption | 0,3 % |

| Relative extension | From 10 to 60% of original length |

| Resistance to aggressive environments | Resistant to water and non-polar solvents (benzene, liquid paraffin, oils). Unresistant to acetone, chloroform, benzene, toluene |

| Melting temperature | 270 °C |

Advantages

Polyester is valued for the following qualities:

- Wear resistance . There are no creases left on polyester products. When worn, the item does not wrinkle and does not lose its original appearance for a long time.

- Bright colors . The fiber lends itself well to dyeing with all known types of dyes, which allows you to obtain almost any shade.

- Easy to care for . Machine washable, dries quickly.

- Hypoallergenic . Polyester, made from high-quality raw materials, does not cause allergic reactions.

Flaws

Synthetic polyester fabric still has some disadvantages that hinder its widespread use:

- Low moisture absorption . On the one hand, this is a plus, but on the other hand, clothes made of lavsan are very uncomfortable in the heat.

- Causes negative skin reactions . Polyester is harmless, but the fact that the skin does not breathe leads to increased sensitivity. People prone to allergies should pay attention to this.

- Not suitable for children's clothing . It is not advisable for young children to buy such things. The exception is outerwear.

Polyester combined with other fabrics

What is polyester in clothing? To improve the quality and properties, polyester is often used in combination with other fabrics.

With viscose

When these two synthetic fibers are combined, a high-quality fabric is obtained.

It is highly durable, absorbs water well, is elastic, resistant to abrasions and puffs, dries quickly and tightens protruding problem areas of the body.

Polyester fabric does not allow air to pass through well, so you will experience discomfort in hot weather.

With clap

Combination of cotton with polyester fibers - what kind of fabric? They called it polycotton. It has been produced since the mid-twentieth century. Mainly used for sewing bed linen, as well as clothing, slings, and home textiles.

Their combination almost completely eliminated the disadvantages that fibers have in their pure form. The best proportion is considered to be a combination of 50% to 50%, or there should be more cotton.

With wool

Most often used for sewing coats. It retains heat, does not wrinkle, retains an attractive appearance for a long time, and is not spoiled by moths. With additional processing, the material becomes windproof and waterproof.

Applications: clothing, fillings and insulation

Polyester finds the following areas of use:

- Production of fabrics for bedding . It can completely replace the usual cotton, or only part of it. Adding lavsan greatly facilitates laundry care.

- Bolon and raincoat fabric for outerwear . The dense material is resistant to moisture and is not blown away by the wind.

- Material for awnings and tents . Polyester itself is not entirely suitable for technical fabrics. But in combination with impregnation and other polymers, it is simply irreplaceable in the production of travel equipment.

- All known types of fabrics, from twill to jacquard. Manufacturers have learned to replace natural materials with lavsan, while maintaining the unique texture of the fabrics.

- Fillers and insulation materials . All insulation materials that have been popular in recent years (holofiber, padding polyester, padding polyester, Thinsulate, etc.) are made of polyester.

The production of clothing and footwear from plastic waste is rapidly gaining momentum. Maybe you also have items made from recycled plastic in your wardrobe?

Production from recycled materials

You should not think that reusing PET somehow worsens the properties of polyester, making it more toxic and of lower quality.

In European and Asian countries, exclusively recycled materials are used for sewing clothes .

Our country is just entering this stage when plastic products can be given a second life.

Of course, recycling in developed countries encourages separate waste collection. In our country, this approach is not widespread enough. But, of course, there are sources of recyclable materials in Russia.

There are companies that produce equipment for recycling polyethylene terephthalate into fiber. They take into account all the subtleties and nuances of the process, which allows them to achieve high quality products. Developers of polymer additives have long proposed good ways to restore the properties of recycled PET .

Recycled plastic fibers are resistant to sunlight and UV exposure.

The strength and manufacturability of recycled PET yarns can be enhanced by adding virgin raw materials .

In addition, there are macromolecule chain extenders, brighteners and antioxidants. The introduction of very small quantities of these additives into processed raw materials significantly improves the quality of the fiber and extends its service life.

Modern pigments and dyes for synthetic fabrics have good hiding power. Therefore, slight variations in the shade of recycled fibers will not be noticeable, especially on dark colors.

, sizing agents (surface coatings) are applied to textiles . Finishing helps protect fabrics from premature aging and wear.

You can find more information about equipment for recycling plastic bottles here.

Important Takeaways

Polyester is a unique fabric with a number of undeniable advantages. To make it, it is necessary to carry out a complex chemical reaction. However, this does not stop manufacturers.

In addition, this material is considered the most popular among synthetic analogues. It is wear-resistant, inexpensive and easy to maintain.

Have you ever come across products that literally fascinated you with their softness and practicality? It turns out that fleece fabric, which is discussed in our article, has these advantages.

If you prefer beautiful natural materials, then cambric with embroidery is an excellent choice. Let's look at its positive qualities using this link.

What are they - the fabrics of the future? Let's look:

© 2021 textiletrend.ru

Fiber technology

The process of producing fibers from recycled polyester is further complicated by the preliminary preparation of raw materials.

Since a high degree of purification from contaminants is a guarantee of a good result, this stage must be approached responsibly.

For the production of thin fiber, only the purest recycled materials , since it is quite problematic to form and draw a thin thread.

Industrial waste is ideal :

- sprues;

- ingots;

- defects in blow molding production (bottles, preforms);

- non-woven and staple fiber trimmings;

- tourniquets, thick ropes.

Container waste PET can be used, but special attention will have to be paid to cleaning it from contamination.

In addition to standard washing operations, it is necessary to use soaking in special chemical reagents, for example, solutions of caustic soda and tetrachlorethylene.

Process stages:

- Sorting . All products must be separated by color and degree of contamination. Caps, closures and labels must be removed with special care, since the slightest impurities significantly reduce the drawability of the finished thread.

- Splitting up . It is advisable to carry out grinding to a small and homogeneous fraction, filtering dust and particularly large pieces. The crusher can be equipped with a metal separator. Read more about polymer crushers here.

- Washing. If necessary, the crushed material is washed in flotation baths and high-intensity washing complexes. For particularly contaminated products, a centrifuge is suitable.

- Drying . To dry PET, storage-type dryers and a pneumatic transport system with several cyclones are used. The stuck pieces separate well and cool in the air flow.

- Extrusion . Since polyethylene terephthalate melts easily, the extruder can be short. It must be equipped with melt filtration and dosing systems, as well as a melt pump.

- Filera . The most technically complex element. The size and number of holes is determined by the type of fiber produced. For textile thread, the thickness of the holes is no more than 0.3 mm. The die is made of high-quality metal to ensure a minimum number of stagnant zones where the material will burn.

- Cooling system . Since the fibers are very thin, they can be cooled by a stream of air in a closed chamber. Next, the already cooled threads go to winding.

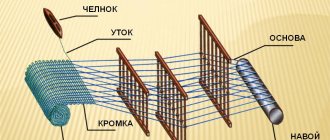

- Formation of tissues. Next, the finished fiber is sent to weaving and spinning machines. The type and technical equipment of textile units depends on the type of fabric. There are many types of thread weave - twill, satin, calico, etc. The equipment of the equipment is determined by the type of finished fabric.