Varieties and methods of obtaining

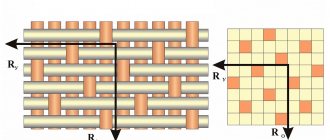

All types of faux fur fabrics consist of two layers - pile and base. The base can be cotton, wool, synthetic or mixed materials, as well as leather substitutes. Currently, acrylic is most often used for pile, which in its properties is close to wool . In addition, polyester, nylon (nylon), natural wool and mixed fibers are also used. The main difference between fur material is the method of its manufacture, according to which the pile fabric is distinguished as:

- Knitted fabric, which is produced on knitting machines by knitting bundles or loops of pile threads into a base of loops.

- Woven (two-layer) using three threads - weft, warp and pile. This results in a two-layer structure, where two layers of fabric are connected to each other by broaches of pile threads, which are then cut.

- Tufted or fabric stitched. To form it, the base is stitched with a pile thread, which is then cut.

- Adhesive, created by gluing pile onto the base material.

The glue method is considered one of the least reliable.

For fur fabrics obtained using the first three methods, the base is usually processed in order to secure the pile. Subsequent processing of fur comes down to cutting (smooth and textured), coloring (layer-by-layer, airbrush, stencil), heat treatment, as a result of which the threads acquire a different structure that imitates the spine and down of natural fur. This is interesting: Canvas fabric: description, linen, thick, other types

How faux fur is made. Types of eco-fur.

The topic of protecting nature and wild animals has long been one of the most relevant and important. Mercy for our smaller brothers should help revive generations of animals whose fur became the reason for their industrial production.

At the same time, modern technical and technological capabilities make it possible to produce high-quality materials, fabrics and fibers in order to successfully imitate natural fur. That is, we are talking about artificial fur.

Now it is even called differently, eco-fur, and it does not look like the unpresentable felted fur coats that can still be found in our mothers’ closets. But fashion shows often present collections where faux fur is used in great variety. Let's figure out how eco-fur is obtained and how its different types differ.

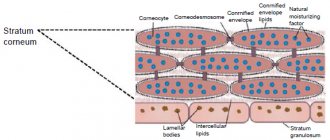

Any faux fur consists of two textures that resemble the structure of natural fur. It has a base in the form of a canvas, usually made of natural threads with the addition of synthetics for strength, and a pile, that is, thin fibers that resemble the structure of fur. In fact, these fibers are obtained chemically, and, in general, are known to those who are involved in sewing and fabrics or crocheting or knitting, since these fibers are also included in mixed types of threads and yarns: nitron (polyacrylonitrile fiber) , lavsan (polyester fiber) and nylon (polyamide fiber).

But let's get back to faux fur. In addition to the types of synthetic fibers, eco-fur also differs in the method of attaching the pile to the base.

Factory production of artificial fur is currently carried out on two types of bases, which are also called primer: on woven fabric or on knitted fabric. Looking from the reverse side of a fur product made from synthetic materials, you can see its fabric base. Fur can be attached to this base in three ways: fabric stitching, knitting and stitching or glue.

The fabric stitching method involves introducing synthetic fibers into the threads of the fabric. Knitting-stitching - when the pile fibers are knitted into the warp threads, adhesive - the fibers are glued accordingly. The threads are then combed until a continuous fluffy pile is formed.

When the pile is worked into the ground, the fur is securely fixed to the base, which is secured with a compound with adhesive properties for greater strength. Using these methods, furs similar to sheepskin, nutria, mink, leopard and others are reproduced. In order for the pile to be completely similar to natural, it is made of different shrinkage, that is, the fur mass contains fibers of different lengths.

The glue method is used to produce fur that imitates karakul, broadtail, and smushka. This is a rather labor-intensive method, when a fleecy thread called “chenille” is attached to the base using a special compound.

Modern production of pile fibers has reached a high level of resemblance to real fur, so much so that attention is sometimes required to distinguish it from natural fur. To verify the origin of the fur, look at its reverse side. See the difference between fabric and leather. The same thing can be seen by spreading the villi to the base. If you run your hand along the growth path, the fibers of natural hair immediately fall into place, while the faux fur bristles a little.

The tactile sensations of high-quality eco-fur and natural fur are very similar, and thin lavsan fibers give it shine. Eco-fur is used for sewing outerwear, hats, shoes, finishing products, and for children's winter clothes. Caring for eco-fur requires both regular combing of the pile and cleaning it. With active use, an item can remain presentable for up to four seasons.

Eco-fur looks great, is pleasant to the touch, warm, and can be quite varied in texture and color. When a product is new, it is often difficult to distinguish it from the natural one at first glance. Only after several seasons of wear, especially in the absence of care, can you see that it wears out and ages differently. But its cost is noticeably cheaper.

Of course, it is difficult to dispute the merits of natural fur, but as an alternative, take a closer look at ecological fur. Perhaps there will be a worthy replacement for the skins of chinchillas, minks, raccoons, arctic foxes and lynxes.

Differences from natural fur

Positive

- Does not require killing animals to obtain it.

- Has a lower cost.

- Faux fur is a textile material, so it is easier to sew.

- Faux fur materials made from chemical fibers are not eaten by moths.

- Lighter in weight.

Negative

- More breathable, so it retains heat less well.

- Shrinks during long-term storage. During use, the fur becomes matted and pilled ("pellets" are formed).

What to wear with faux fur

You can, as usual, get inspired by the perfect combination of fashionable items with an equally fashionable faux fur coat in street style.

pros

- If you wear faux fur, you don't feel guilty about killing animals. And even if you have a lot of different fur products in your wardrobe, your conscience is completely clear.

- Another advantage of such fur is an important feature in our time - price. The use of synthetic fibers allows you to spend less on production - therefore, the price of such products is much lower than for fur coats made from natural fur.

- The production of artificial fur nowadays is at a very high level, so its quality is not inferior to natural fur. The products do not require special storage or special care, they are easy to clean, they cannot be damaged by moths, and they can remain shiny and beautiful for a long time.

- Artificial pile can be of any length and color, and even the most daring color schemes look quite authentic, while natural fur does not tolerate experimentation; its coloring significantly reduces the quality of the product and negatively affects its appearance.

Natural fur

If a fur coat made of faux fur is difficult to distinguish externally from a natural one, then it is easy to detect by touch. Natural fur is fluffy, it always feels soft and warm, inherent only to animal origin; its fibers lie unevenly and have different lengths. Natural fur fibers always create shine of the product and special smoothness and elasticity.

However, the quality of natural fur depends on many factors, and not only on compliance with all the rules for dressing the skin. It should be noted that the maintenance of animals or the time of extraction of natural raw materials is of no small importance. If you violate any established rules, you can get short-lived and low-quality fur. And you will find out about this when bald patches soon appear in your fur coat in places subject to greater friction, or after repeated exposure to rain or snow, when the fibers begin to fall out.

Natural fur is afraid of moth larvae, which spoil the appearance of the product. Cleaning products made from natural fur is quite difficult. A certain temperature regime is required for storage and cleaning. And finally, products made from natural fur are expensive.

Description

Faux fur consists of a ground on a woven, knitted, or artificial leather base, to which a pile of chemical or natural textile fibers, including fibers of animal origin, such as sheep's wool, is attached in various ways.

The pile can be plain-dyed (single-color), melange (multi-color) with printed patterns, including those imitating the natural color of the fur of various animals. Also, fur finishing may include curling or embossing. The pile is trimmed to the required length.

Story

Faux fur first appeared in 1929. At that time, it could not be considered truly artificial, since alpaca wool . The color of the fur left much to be desired, usually gray or brown, it was not at all like natural and was very short-lived. Completely artificial fur , consisting of 100% synthetic fibers, was created only in the 50s. Such fur was usually made of acrylic polymer, that is, it was essentially plastic. Somewhat later faux fur became a very popular material, firstly, it was possible to make fur of any color and shade, and secondly, its very affordable price was captivating.

Pros and cons of faux fur

Faux fur coats are made from acrylic polymers containing complex chemical components and petroleum products. Even after the onset of the apocalypse, such a fur coat will decompose for several hundred years. Well, the waste from production where synthetic fur is produced pollutes the environment so that both people and the above-mentioned fur-bearing animals suffer as a result.

Dries Van Noten Miu Miu

Nina Ricci Bottega Veneta

For very humane people who still really love natural fur, there is also a solution. Over the last few years, fur coats made from natural wool have become popular, but the wool is not torn from the animal, but carefully combed and glued to the fabric from which the coat is sewn. The famous Teddy Bear Coat from Max Mara is made using exactly this technology. This is camel hair. Using the same technology, similar coats are sewn from sheep and llama.

Max Mara Burberry

Which fur coat is warmer? Depends on the owner of the fur coat. Some people are fine with a coat in winter, but others wrap themselves in five sweaters and a down jacket and still feel cold. I have all kinds of fur coats. From natural to brushed. I can’t say that any of them are significantly warmer. I also feel warm in acrylic, especially with a warm sweater underneath. In any coldest situation, an ultra-thin down jacket worn under outerwear will save you. I'm all for layering and warmth.

By the way, geese don’t voluntarily give up the down for your favorite down jacket either.

In our country, a mink coat is much more than just a fur coat. This is both a status and an object of desire and a way to look richer than we actually are. I know a lot of stories of our women when a mink coat was bought on credit or in order to buy it they had to save for a very long time, denying themselves something.

Only in Moscow in the winter half of the women in the subway car are dressed in mink. In our country, it is still believed that faux fur is cheap and the lot of teenagers. But, hand on heart, I can say that you can look cheap and out-of-date even in the most expensive mink coat with the most beautiful mother-of-pearl button (and this happens very, very often). No matter how expensive your favorite fur coat is, alas, it is not a vaccine against bad taste.

The purpose of faux fur is not to imitate natural fur, but the exact opposite. The more similar the fur is to the skin of a non-existent acrylic animal, the more beautiful it is. Such a fur coat will cost less, and will be no less warm than a sable one. The main thing is HOW to wear it. Well, a bright color, an unusual texture or a complex print is only a plus.

Minuses

- Faux fur is less environmentally friendly. For its production, acrylic and polyacrylic polymers are used, which contain water, coal, limestone and petroleum products. The pile of such products is much stronger than natural, which means that it biodecomposes much longer.

- Another disadvantage may be the reduced frost resistance of artificial fur. Therefore, it is not suitable for extreme weather conditions. However, scientists and designers are working to improve its qualities.

- The external differences between artificial and natural fur are practically invisible, but to the touch natural fur is much softer and more delicate than any artificial fur.

Of course, if you are a lover of natural fur, no one will sprinkle flour or paint on you on the streets - this is the privilege of the stars. However, when buying a fur coat made of natural pile, you should not choose the “Ussuri tiger” or other rare animals, let them live a little longer on our planet. Well, the more people use artificial fur, the more its quality will increase. So who knows which material will be more popular in the future?

Don't want to see ads? log in

This is interesting: Printed fabric - what is it. Types with drawings, photos

Product care

Faux fur is quite easy to care for, and following simple rules will keep the product in perfect condition for more than one season.

You may be interested in Ready-made patterns and sewing of a cat bed with your own hands

Spot on fur

Mechanical friction in the same places should be avoided. Faux fur, just like natural fur, is afraid of dampness, so you need to try not to get exposed to rain or snow so that the item does not lose its luster - it is very difficult to tidy up. Since artificial fibers are highly flammable, you need to protect them from exposure to high temperatures: do not leave the product near an open flame.

Synthetic fur is easy to wash at home:

- delicate wash mode;

- the optimal water temperature is not higher than 40 °C;

- do not dry or spin in a washing machine;

- To dry, the fur is straightened and left in a horizontal position.

Caring for the material

To add fluffiness to a dry product, comb it with a sparse comb. Cleaning with a vacuum cleaner is allowed. Store in a well-ventilated area, away from moisture and direct sunlight, on hangers. It is not recommended to fold or roll the products so that the pile does not wrinkle or form creases.

Advantages and disadvantages

It is used for sewing outerwear.

Technologies for the production of modern textiles make it possible to bring synthetic and natural materials as close as possible in their properties. It is very difficult for a consumer who does not have special skills and experience to distinguish high-quality faux fur from its natural counterpart. The type of raw material, manufacturing method and additional processing provide the advantages of the material:

- The low cost of the material is its undeniable advantage, as it makes faux fur products affordable for people with low incomes.

- This material is much easier to care for than natural ones. It can be washed and cleaned with a vacuum cleaner, besides, you should not be afraid of the appearance of moths and harmful microorganisms; they simply are not found in synthetics.

- Faux fur fabric has a textile base, so it is easy to cut and sew products from it. In addition, the dimensions of the canvas allow the item to be made from a single piece of material, and not from individual skins, as when working with natural fur.

- Artificial pile can have the most incredible colors, and this only improves the appearance, while such experiments with natural material significantly reduce the quality of the product.

- The production of faux fur fabric does not harm the environment, since no one has to take the life of animals for the sake of a hat or fur coat.

The material has several disadvantages.

- The high breathability of faux fur reduces the thermal insulation properties of the fabric. Natural products are much warmer than artificial materials.

- Low wear resistance.

- Synthetic fibers quickly accumulate static electricity and attract dust.

Advantages and disadvantages

It can be argued that it is now possible to visually accurately reproduce the fur of any animal, although the differences between them will be noticeable even at the touch. The advantages of artificial fur fabrics are:

- no cruelty to animals and conservation of nature;

- affordable price;

- resistance to damage by insects and microorganisms;

- ease of care;

- variety of choice;

- simple cutting and sewing that can be done without professional training.

However, faux fur material also has certain disadvantages. First of all, due to its high breathability, its heat-protective properties are much worse than those of natural fiber (which, however, only matters for cold climates). Synthetic pile tends to become electrified, and therefore gets dirty faster. In addition, the wear resistance of such materials is almost always lower than that of natural analogues.

Features and characteristics of faux fur

Man-made fur material can be obtained from various raw materials and using different technologies, but its structure is always the same. It consists of two layers - a smooth base and fluffy pile. The base can be woven or non-woven material made from:

- cotton;

- synthetics;

- wool;

- mixed fibers.

The pile is most often formed from thin synthetic threads (acrylic, polyester, polyamide), less often natural wool. The connection of pile and base can be done using different methods. The simplest and least reliable of them is adhesive, which is now rarely used. More reliable is the molding of fur in the process of creating the main fabric, which can be:

- woven, in which, in addition to the warp and weft threads, a third one is also used, forming villi;

- knitted, when long loops or bundles of pile fibers are knitted into the warp loops;

- thread-stitched or tufted, stitched with pile thread.

After the fur fabric is produced, the base is processed to secure the fibers, and then they are cut, including at unequal heights, and dyed to imitate natural fur or create original color effects. For this, various stencils, airbrushing, layer-by-layer painting and other complex methods are used. To imitate natural curls and form a heterogeneous structure of the pile, it is heat treated.

Modern technologies for the production of artificial fur have reached such perfection that it is very difficult to visually establish the difference between natural and man-made material . However, their characteristics will certainly differ. First of all, artificial pile retains heat much worse than natural pile, so fur coats and hats made from it are not suitable for harsh winters. In addition, synthetic threads are hard to the touch, they become electrified and attract solid particles that pollute them, and wear out much faster than their natural counterparts. At the same time, fur fabric has many advantages, namely:

- uniformity of texture and ease of cutting;

- variety of types and colors, including creative ones;

- low cost;

- Moth resistance;

- easy to use and maintain;

- symbolizes the protection of nature and humanity towards the animal world.

Why is faux fur better than natural fur?

It has many advantages. It is easy to use and does not require careful maintenance. Such a fur coat would rather go out of fashion than lose its shine, lose its smoothness and roll into lumps. It can easily withstand rain, snow and hail. Therefore, practical fashionistas are increasingly choosing eco-fur over natural fur. Another reason is the undoubted cheapness of such products. Any woman can afford a fur coat or sheepskin coat with faux fur. And at the same time it will look expensive and elegant.

Faux fur is stylish. Most of the world's designers refuse natural products, arguing that eco-products better reveal the individuality of their owners. It helps to embody the most daring ideas of creators - plain and multi-colored, classic and non-standard, straight and asymmetrical fur coats - the choice is huge. Faux astrakhan, muskrat or rabbit fur is also used when sewing sheepskin coats, vests and even sweaters and cardigans. Finding a suitable model in numerous brand stores is not difficult.

High-quality artificial fur contains natural fibers that allow the skin to breathe and maintain a comfortable microclimate even in the coldest weather. Since the products are made from solid fabric, there is no risk that the seams will stretch and turn the item into a bag. The only condition is that they need to be stored in well-ventilated areas.

What is faux fur made from?

It’s not called eco-fur for nothing. It is pleasant to the touch, warm and soft, that is, as close as possible to natural characteristics - and at the same time absolutely safe for the skin. Its fibers are distributed evenly over the canvas; they have a uniform structure that imitates the fur of an animal. Eco-fur fabric is formed by polyacrylonitrile fibers in combination with natural viscose. The basis for the fur material is knitted fabric. Faux fur (mink, fox, raccoon and other types of wool that it imitates) is an environmentally friendly material.

Types and methods of production

The name of a particular type of material is determined by the variety of the original that it imitates: it can be artificial mink, astrakhan fur, arctic fox, etc. The structure of artificial fur is similar to natural fur and consists of a base (soil) and pile. The ground is mainly made from cotton yarn, but sometimes, for strength, synthetic fibers are woven into it. To increase the wear resistance of the fabric and better fix the pile, its reverse side is glued with foam rubber, latex and sizing - a substance that contains fats, starch, cellulose ethers, etc.

Fur can be made from both synthetic fibers - polyester, acetate, nitron, etc., and natural fibers - cotton and wool. The most valued are wool and cotton fabrics, which most accurately imitate real fur. Pile is often made from several types of fibers, including those with varying degrees of shrinkage. This makes the artificial material even more similar to natural.

To protect the fur from moisture, fading and creasing, it is treated with hydrophobic impregnations and special salts, polished with ethyl, etc. To give the most natural appearance, the pile is subjected to repeated combing, cutting, dyeing, etc. Through special heat treatment, the length and structure of the pile changes , due to which “guard hair” and “undercoat” are formed.

Depending on how the fur fabric is made, there are the following varieties:

- Knitted. In this case, tufts of pile are woven into the base using a special machine. The fur is securely fixed in the ground, but for greater reliability the underside is covered with film.

- Woven. By intertwining the warp, weft and pile threads, two fabrics are made, connected by pile. Next, the cloth is cut in the middle, and two pieces of fur with the same length of pile are obtained from it. To prevent the fibers from falling out, the soil is glued with a special compound. Woven faux fur is more lush and dense than other types of fur, reminiscent of natural fur.

- Tufted. This type of fur is also called fabric-stitched fur and is made by a buttonhole machine by stitching the pile through the base. In this case, loops are formed on one of the sides, which, after cutting, straightening and combing, turn into fur.

- Glue. This method is the most labor-intensive and involves gluing chenille (twisted pieces of cotton fibers strung on a nylon or viscose thread) to the ground. To ensure a tight fit, the fibers are placed by electrifying them. This fabric is characterized by the least wear resistance, but also the greatest similarity to natural fur.

Production of eco-fur

Faux fur production is a largely automated process. The manufacturing steps involved include the construction of synthetic fibers and fabric.

Chemical synthesis of fibers

• 1 The production of faux fur begins with the production of synthetic fibers. While different types of polymers are used, modacrylic polymers provide a good illustration of the fiber manufacturing process. First, acrylonitrile and vinyl chloride monomers are mixed together in a large stainless steel container. They are forced into a chamber in which the pressure and temperature increases. The mixing blades are constantly in motion and the polymerization process begins. The resulting white powdery resin is then turned into a thick liquid by dissolving it in acetone.

• 2 The polymer liquid mixture was then pumped through a filter to remove undissolved particles. From the filter, the material is pumped through a spinneret, which is immersed in a water bath. Spinnerets are similar to shower heads, and when the polymer is extruded through them, it emerges as a group of continuous fibers called a tow.

• 3 The tow is then pulled along the conveyor belt and stretched through a series of pulleys. As the tourniquet is stretched, it is also washed and dried. As it dries, the acetone evaporates, leaving only the polymer.

• 4 After various quality control checks are performed on the layers, they are moved to the next processing step. Here the polymers are soaked in solutions of dyes and colors. While this is not the only step in the production of faux fur polymer at which the fibers are dyed, it is typically the point at which the solid colors of the acrylic fibers are produced to further produce the unique fabric known as ecofur.

Fur production

• 5 While the fibers provide the primary texture, the backing provides most of the fabric's structure—faux fur. Next comes the next stage of production, in which the fibers will be attached.

• 6 In order to convert fibers suitable for clothing, four different methods can be used. The most basic method is the weaving process. In this process, the fibers are looped through and interwoven with the supporting fabric. Although this method is quite slow, it can produce a wide range of fabric forms - eco-fur. Another method of fake fur production is called tufting. It's like weaving; however, it produces clothing at a much higher rate. Circular knitted loops and tapes, knitting and other methods of counterfeit fur clothing products. Sliver knitting uses the same equipment used in jersey knitting. This makes it the fastest and most economical of all fake fur clothing production technologies, and it is also one of the most commonly used src=»https://mirofox.ru/image/catalog/articles/2017-06-01_211521.jpg» class =”aligncenter” width=”521″ height=”709″[/img]

Finishing touches

• 7 The conditions for imitation of natural fur clothing are interpreted differently. First, you need to ensure that the faux fur remains unchanged after it is exposed to heat. This heat setting process preshrinks the fabric, giving it improved stability and expanded fiber diameters. Wire brushes are then passed through eco-fur to remove loose fibers from the fabric. This process is known as tigering. Rough cutting of the fibers, cutting them with a set of screw knives gives them the same length. The sheen of a fabric can be adjusted using a method known as electrofying. This is a polishing method that involves combing the fabric with a heated, grooved cylinder in both directions. The next treatment is the application of chemicals such as resins and silicones, which improve the feel and appearance of the fiber. Coloring to imitate certain animals can also be improved in this production. Another round of electrofying can be done, as well as finishing shearing, to remove any remaining loose fibers. Depending on the type of faux fur, foil stamping to simulate curls may also be done at this stage of production.

Main characteristics. Advantages and disadvantages

Like products made from natural fur, “artificial” fur coats and jackets have their own advantages and disadvantages.

You might be interested in this Features of Alcantara: properties and applications of the fabric

The obvious advantages include:

- Variety of colors and structures: any color schemes, combinations, imitation of natural colors, different lengths of pile, thickness of fabric, density of padding.

- Relative strength, good wear resistance, as well as heat-protective properties, which are sometimes not inferior to natural products.

- Easy to sew. Since the base of such fur is fabric, it is easy to cut and sewing the product is extremely simple.

- Affordable price. Compared to products made from natural material, artificial fur coats cost significantly less.

- Easy care. Synthetic material is easy to wash and cannot be dyed. Storage does not cause any difficulties: such a fur coat will not be eaten by moths and it does not have a specific odor or yellowness.

- Ethicality.

Color options

Important! In the production of eco-fur coats, animals kept in the terrible conditions of fur farms are not harmed, wild animals are not exterminated, and their natural population is preserved.

Wrong side

There are also disadvantages:

- Not environmentally friendly. Synthetic fibers are mainly made from petroleum products, and petroleum is a non-renewable natural resource and its extraction is accompanied by environmental pollution.

- Fur coats are inferior in thermal insulation properties to natural ones: they are less warm, since the pile has greater breathability.

- Artificial material wears out quite quickly, its pile is more susceptible to crumpling and can become matted.

- Synthetic fibers are more likely to accumulate static electricity, making dirt more difficult to clean, especially in shoes and upholstery. Stagnant stains cannot even be bleached (if the material is light).

Important! Artificial material practically does not decompose in nature, but such fabrics can be recycled.

Care

Faux fur , like any brushed material, tends to form pills and mat. It should never be exposed to high temperatures, such as washing in hot water or drying near heat sources, otherwise it may lose its shine and shrink (reduce in size). In general, it is better not to wash things made of faux fur, but to dry clean them. If moisture gets on the surface of the faux fur (rain, sleet, etc.), the item should be shaken and dried on hangers in a well-ventilated place, away from heat sources. Combing faux fur is not recommended. Or you need to do this with a comb with very rare teeth.

Faux fur - what is it?

Faux fur is a material consisting of two elements: base and pile. Fluffy fibers are often attached to fabric, but cardboard and leather substitutes can be used. It is not always possible to distinguish natural or artificial fur by external signs. But if you look at the inside, you will see not a tanned skin, but a fabric or other base.

The popularity of artificial material is growing. It is used to make products from iconic world-famous clothing brands. Faux fur is not always synthetic. Manufacturers can use blended fibers as well as pure wool or silk. Such varieties are more expensive and have comparable properties to natural animal skins.

Product overview

Beautiful, elegant faux fur coats are a trend in recent years.

Sofa cover

World fashion houses have long adopted the advantages that synthetic material has; it allows you to create, creating new classics and extravagant, creative things:

- A favorite of recent seasons is Teddy Bear Coat. This coat is like a soft plush toy that the girl does not want to part with.

- Bright fur coats with long pile demonstrate the extraordinary rebellious nature of its owner.

- Animal print for all times. Especially if such fur is practically indistinguishable from natural fur. And no one will accuse the seals of illegal mining.

- Noble “astrakhan fur” is the height of elegance. A colored astrakhan coat makes the look exclusive.

- A combination of several colors and textures in one product. This coat is clearly not for everyone. But the more noticeable and brighter it will stand out among the gray everyday crowd of the big city.

Choosing eco-fur

Secrets of choice:

- Try the pile to the touch: is it soft or hard, smooth or prickly, puffy.

- Don't be afraid to touch and shake your faux fur coat. The pile may fall off in small quantities from the seams, but the fur should not “shed” too actively.

- A low quality product has a distinct, persistent “chemical” aroma.

- There must be labels. And they must contain all the necessary information about the composition and care of the product.

- It is worth running the fur “against the grain”; if it receives an electric shock, it means that the product has not undergone electrostatic treatment. Such a fur coat will constantly become electrified and attract dust and small debris.

- Colored fur should not stain surrounding objects. You can take a handkerchief or paper napkin and run it over a bright fur coat to see if any dye remains on the surface.

Color option

Additional Information! It is advisable to check the quality of the seams and the direction of the pile by hand. An incorrectly sewn part (with the pile in the opposite direction to the main ones) can ruin the appearance of the product.

Selection rules

A detailed examination of the properties, applications and types of artificial fur allows us to draw conclusions about the exceptional practicality of the material. How do you choose fur?

- There is an opinion that faux fur looks cheap and is inferior to natural fur in all respects. This is not true; most often the materials cannot be distinguished visually. That’s why it’s better not to choose uneven, matted fur with an “icicle” effect – it’s of low quality.

- Before purchasing, you need to make sure that the pile does not fall out and that there are no bald spots on the canvas. Pass a piece of damp cloth over the fur - if the fibers do not stick, you can safely buy the product. The most durable material used to create fur coats is polyester. It's good if it's listed in the composition.

- You should read the text on the label, which indicates the composition of the fur and basic recommendations for caring for it.

- Check the quality of the seams and the direction of the pile. An incorrectly sewn part with the pile up can ruin the appearance of the product.

- The fur should not smell of anything chemical. The presence of strong odors indicates the use of unsafe dyes or indicates a serious violation of production technology.

Application area

izdelie-1

izdelie-2

izdelie-3

izdelie-4

The scope of application of artificial fur is wider than that of natural fur:

- outerwear (fur coats, hats, vests, jackets, trim);

- outerwear lining;

- shoes (outer side, inner side, and insoles);

- accessories (muffs, collars, mittens, bags);

- furniture production (upholstery of upholstered furniture);

- Stuffed Toys;

- floor coverings (carpets, carpets, carpets).

On a note

The production of artificial fur is also organized in Russia. Among the largest manufacturers are CJSC Faux Fur, Classic SPB and others.