Do-it-yourself rubberizing of fabric - Metalist's Handbook

As you know, fabrics are used not only for sewing clothes; they can often be found in bags, backpacks, jewelry and many other things.

At the same time, it is quite natural that completely different requirements are imposed on the fabric used in the manufacture of bags than on those used in tailoring.

Therefore, manufacturers have come up with many types of materials containing rubber, neoprene, and even Teflon.

Pleated fabric is practically never found in such products, although sometimes this is possible. Decorations such as Provence are also rarely used, but elastic bands are used quite widely, and sometimes worsted fabric is used.

Characteristics and use of rubberized fabric

Rubberized fabric is one of the oldest ways to protect things from moisture. Almost any type of fabric can take part in the production of this material: cotton, linen or synthetic. The roll is impregnated with rubber-based glue and then dried.

When all the volatile substances have evaporated, the rubber remains firmly attached to the fibers of the web. Rubberized fabric does not allow water to pass through, withstands almost any household chemicals, and is also durable and elastic .

It has only one serious drawback - like regular rubber, it can be easily punctured, which will negate all its advantages.

In addition, rubberized fabric is not very beautiful (it can be confused with neoprene), which is why it is used less and less, mainly for the production of workwear.

However, sometimes it can be found as a design element, since its smoothness can add zest to even a handbag. You just have to take into account that it is not possible to find such fabric in the Provence style - most often it is plain.

It is also not used to make elastic bands because it is too dense. Moreover, it is not even often used together with elastic bands, since they allow water to pass through by definition.

Also, sometimes rubberized fabric is used to protect the corners of the product from abrasion, since its smoothness conceals friction.

Caring for this material is extremely simple - just wipe it so that not even a trace remains of any dirt. But damage from severe frosts (cracks) or fire causes irreparable damage, and it is impossible to sew up the damaged area - you need to change the entire piece, otherwise the rubberized fabric will look terrible.

Water-repellent Teflon

Teflon, which is commonly considered a non-stick coating for frying pans, has another application: it is used in the production of water-repellent fabrics.

It should be remembered that one of the main properties of Teflon is that it is not enveloped by almost any liquid. Therefore, even if the Teflon fabric allows water to pass through, it will remain dry and clean.

As such, fibers are not made from this material; Teflon is simply used to cover the fibers of any fabric (both natural and synthetic), which protects it from most dirt and moisture.

If desired, you can even find elastic from fabric treated in this way, or fabric dyed in the Provence style, since Teflon does not affect the coloring.

In addition, due to the special properties of the polymer, intact Teflon fabric will not let a drop of moisture inside. And the properties of Teflon, such as fluidity and elasticity, allow the coating to be extremely durable, because even when the fibers are stretched, it is not damaged .

Teflon rubber bands are extremely rare, since their price is usually too high, but the quality and durability of such rubber bands are at the highest level. Externally, the treated canvas does not stand out in any way, so you can distinguish it only by trying to wet it with water.

It is worth keeping in mind that Teflon fabric is completely harmless to humans, except when it is heated to temperatures above 300 degrees, which causes the release of toxins. And caring for it is no different from the original fabric, i.e.

If Teflon is applied to a cotton thread, then the care rules will be the same as for ordinary cotton fabric. It will only be easier to wipe off dirt from the Teflon fabric.

Worsted fabric is usually not coated with Teflon, but such options exist.

Properties of Cordura

A less exotic fabric is cordura, which is a fabric made of specially twisted nylon fibers. It is vaguely similar to worsted fabric, but differs in shine.

Its only disadvantage is low flexibility, which is why Cordura is most often used for making backpacks and workwear.

However, this fabric has a beautiful shine, which allows it to be used for some types of jewelry, especially in combination with neoprene, but elastic bands cannot be made from it due to its large thickness.

In addition, a thing made from this material does not get wet well, but also takes a very long time to dry, which makes it unsuitable for serious hiking. Otherwise, cordura is a very unpretentious type of fabric that can withstand everything except an iron heated to 200 degrees.

Practical neoprene

Neoprene is another specialized material. Most often it is used to make various swimsuits and covers, since it is waterproof and durable. The main disadvantage of neoprene is its color - it only comes in black or dark gray.

On the other hand, it dyes quite well, so you can also find neoprene in the Provence style. The only disadvantage of neoprene is that it is difficult to process, so you most likely won’t be able to sew something out of it yourself, and all that remains is to look for finished products.

Due to its properties, neoprene, like worsted fabric, is a material used in the defense industry.

How to sew elastic onto fabric using a machine correctly

Elastic tapes in sewing are used to tighten fabric, form gathers and fix part of the product in a certain place. In many cases, elastic bands are preferable to ribbons or cords threaded into a drawstring.

With them, the gathered part of the product can instantly stretch and contract back to its original shape, no need to fuss with ties. The material to which the elastic is sewn retains the folds of the desired shape; they do not need to be constantly straightened.

Therefore, even beginners need to know how to sew elastic to different parts of clothing - this is one of the key tailoring skills.

Elastic materials are divided into two main types. The first is traditional underwear elastic bands of varying degrees of softness. They differ in width, shape, and the presence of decor (ruffles, lace). Such tapes can be sewn both manually and on machines, household and industrial.

The second type is stretchable threads, which are pulled from a rubber synthetic mass and sold in spools. The elastic base in them is covered with cotton fibers in a spiral.

Threads are used primarily when sewing on a machine, but you can also work with them using a crochet hook - on mesh fabrics.

There are general operating rules for all types of elastic bands.

- You cannot break the rubber “ties” inside the tape, so you need to sew carefully along it, watching the needle - otherwise the product will be deformed.

- The needle is placed so that it passes between the elastic threads along the fabric “layer”. Therefore, in their work, craftsmen often use a zigzag stitch that does not affect the central base fibers.

- When sewing on the elastic, you need to make sure that the tension is uniform along the entire length and that the folds are the same everywhere.

.com

Where are rubber bands used?

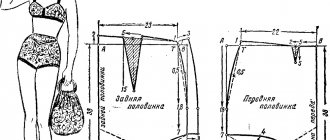

Elastic inserts in prominent places are used mainly on women's and children's clothing. In men's clothing, they are rather needed for cuffs, shaping the bottom of trouser legs and shoulder clothing in a street-sports style.

Most often, elastic bands are inserted along the cut line of the neckline and sleeve caps in products with open shoulders. The thick tape holds the item securely on the figure and forms beautiful folds on the chest and upper arms.

It is used to design blouses, tunics, dresses made of airy or flowing fabric.

Elastic bands are often sewn onto:

- chest (in several rows) - a section completely stitched with elastic bands secures the clothes, you don’t even have to make straps;

- part of the back at chest level - the elastic also runs in several rows, serves for a better fit of the product (the front part is designed in a different way);

- level under the chest - this is how an empire-type silhouette is formed, with a beautifully defined bust and freely flowing folds under it;

- sleeves - elastic sewn into the cuff or at shoulder level helps create impressive volume;

- waist - neatly outlines a line, forms lush folds above and below it, does not require tightening and fastening, unlike belts and sewn-in zippers;

- hips - this way you can create an allowance that hides the belly or creates soft waves above the gather line.

If you combine several elastic bands on a blouse - on the sleeves, shoulders, waist - you can create an elegant model in the “Peisan” style. Vertical stitching with elastic on a dress or top is needed when creating transverse drapery. There are many options for using elastic tape, as well as ways to attach it to fabric.

miladys.ru

Simple ways to sew in elastic bands

If you don't know how to sew elastic to fabric on a machine, you can practice with the simplest stitches. Among all their types, a zigzag is best suited for fixing elastic threads and ribbons.

It is simple, can be easily “imitated” by hand sewing (if you don’t have equipment) and does not require long training. Zigzag stitching is provided on almost all household machines, regardless of the year of manufacture.