Anyone who has tried to sew something from knitted fabric knows how difficult it is sometimes to overlock sections with an overlocker without stitch defects, and sometimes it is simply impossible to sew knitwear on a regular machine. Gaps appear in the stitch, loops form at the bottom of the stitch, and sometimes even the thread breaks.

Why does this happen, why do machines like Chaika or Podolsk generally “refuse” to sew knitwear? Is it possible to set up a regular straight-stitch machine so that it sews knitwear without stitch defects?

You will learn the answer to all these questions, as well as what a knitted overlocker and differential are, and what is different about a sewing machine designed for sewing knitted fabrics (coverer, coverlocker) in this article.

Sewing machines for sewing knitted fabrics

Sewing machines for sewing knitted fabrics are a special type of sewing equipment and they have one thing in common - the method of stitch formation. The stitch for sewing knitted fabrics is called a chain stitch and it is formed using a looper. In the photo on the left is a flat-stitch machine, on the right is a knitted overlocker.

In a conventional machine (lockstitch), the bottom thread is wound on a bobbin, the bobbin is inserted into the bobbin case, the cap is inserted into the shuttle, which is why it is called a lockstitch. So, for a chain stitch, such a multi-layer “matryoshka” is not required, and the thread is simply threaded into the looper directly from the bobbin.

Externally, the chain stitch from the inside resembles a “pigtail” and if you pull the edge of a loose thread, the entire seam will unravel. This is one of the disadvantages of the chain stitch, however, this property does not apply to the overlock stitch, but only to the flat seam.

In addition to the cover stitch, a flat seam can only be performed by a carpet locker. Moreover, the seams of the carpet can be either overlock or cover-stitched. It’s true that the price of such a universal household machine is equal to the cost of two: an overlocker and a stitcher.

In this article we will look at the features of the formation of a three-needle flat seam on household cover stitching machines. If you are interested in other capabilities of cover stitching machines, see the article Industrial Cover Stitching Machine.

Tricks for sewing knitwear on a regular sewing machine

Many who have tried to sew knitwear on a regular sewing machine have noticed that the machine often refuses to make a beautiful and even stitch. Gaps form in the knitted stitching, the bottom thread loops, and sometimes breaks. Why does this happen and how can I fix it?

Firstly, for sewing knitted fabrics, a special knitting machine is used, it is called a flat-stitch machine - an open stitch machine or a chain stitch machine. The seam on the reverse side looks like a “pigtail”. Look at any factory processing of a T-shirt and you will see this.

Secondly, for sewing sections of knitted fabric, a knitted overlocker is used, which has a differential (stretching fabric) rake with the simultaneous laying of a sewing chain stitch.

And thirdly, special needles and threads are used for sewing knitwear. The last point is decisive for your sewing machine, so let's figure out which needle you need to sew knitwear, what threads you need to use to get a high-quality stitch, and consider other factors that affect the quality of the stitching.

Needles for sewing knitted fabrics

There are many reasons that affect the quality of the stitch formed when sewing knitwear. One of them is an incorrectly selected needle. Universal needles, which are most often used on sewing machines, are “poorly” suited for sewing knitwear. Not only can the sharp edge of the needle damage the weave of the knitted fabric, but it can also cause the loop near the eye of the needle to be too small. And the nose of the shuttle simply passes by it without catching the top thread. As a result, gaps appear.

Replace the utility needle with a special needle with a rounded point designed for sewing such fabrics. A needle with such a point does not pierce the knitted fibers, but passes between them and creates better conditions for the formation of a loop. The packaging with these needles says “Jersy”, and “ball point” means that the needles have a rounded point.

However, you should know that buying a package of special knitting needles does not always solve the problem, especially for old-type sewing machines such as Podolskaya or Chaika. There are a number of other factors, which will be discussed below.

This diagram shows a knitted weave of stretch fabrics. Outwardly, it resembles knitting or machine knitting, which is why it is called knitted fabric. “Springy” loops give fabrics many useful qualities, such as stretchability, low creasing, etc., but at the same time they create certain difficulties when sewing them on ordinary household sewing machines.

Threads for knitted fabrics and their tension

Not a single lockstitch machine likes to sew knitwear. Knitwear for a lockstitch sewing machine is a test that not all machines can withstand. True, modern household machines cope with this task quite well, provided that certain requirements are met. As you already understand, one of them is high-quality thread and its correct tension.

Sewing threads should be thin, elastic and durable. Basically, all types of modern threads available for sale in the accessories department correspond to these parameters. But, nevertheless, you need to experimentally determine which type of thread is best suited for your machine.

Naturally, you need to “forget” about thick finishing threads, and even more so about threads from your grandmother’s old stocks. Ideally, threads on large conical bobbins are suitable for sewing knitwear, but since they are quite expensive, use threads on small bobbins, such as “Ideal”.

Before sewing knitwear, you need to correctly adjust the tension of the upper and lower threads.

Typically, the bobbin thread should not be adjusted, but when sewing knitwear, this can often eliminate thread looping in the stitching. If, when you tighten the top thread, the looping at the bottom does not stop, then try to slightly loosen the tension on the bottom thread.

Please note that when you sew pieces of knitted fabric, the stitching will be looser in one direction (usually transverse). This “effect” cannot be eliminated using tension. It’s just that the knitwear stretches under the influence of the foot and the teeth of the rake, and then takes its previous shape and the stitches are loosened. By the way, the presser foot pressure also needs to be adjusted.

To eliminate this, use stabilizers (gaskets), including pre-cut strips from newspaper. A paper strip is placed under the fabric, and then carefully pulled out of the seam. By the way, often just such a “cunning” method can eliminate gaps in the stitching of a Podolskaya or Chaika sewing machine.

But, naturally, this is too extravagant a method that is undesirable to use. If you have replaced the needles and selected the threads, adjusted the tension, but the looping and skipping have not disappeared, then you need to adjust the sewing machine. But only an experienced craftsman can set it up for sewing knitted fabric.

What is the difference between knitted overlock

Almost all modern household overlockers are knitted overlockers. The main difference between a knitted overlocker and a regular one is that a knitted overlocker has a special rack design (teeth under the foot). During operation, the lath specifically compresses (stretches) the knitted fabric, and after stitching, the fabric is stretched (pulled) back. As a result, the seam is stretchable and can withstand more tensile load.

For example, if you sew knitted fabric on a regular machine, and at the same time tighten the thread tension strongly to eliminate the slack in the stitching, you will get a very beautiful stitch, but not strong. Pull this area with your hands and your beautiful seam will simply burst. This is the main purpose of knitting machines - to create an elastic and stretchable seam.

Overlockers with a differential rake can sew not only knitwear. This function can be easily disabled using a special knob. And even, on the contrary, you can “force” the rail to collect the fabric. You need to know that overlockers of older models, including class 51 overlockers, cannot efficiently process knitted fabrics. And don’t be surprised if the connecting seams of knitted clothing, processed only with a three-thread overlocker, will burst over time.

Other reasons why the machine does not sew knitwear

Well, one last thing. A Podolsk sewing machine or a Chaika sewing machine often refuses to sew knitwear at all. And even a master cannot always set it up for sewing knitted fabric. If you want to check the work of a sewing machine repairman, ask him to sew a piece of the most “harmful” knitted fabric at the end of the job. If the line does not have even one omission, it means that this is a “good” and experienced master.

Older machines have different adjustments for the interaction between the needle and the nose of the shuttle. After all, at the time when they were released, no one suspected that such fabrics would be used all the time. Therefore, modern machines are configured for sewing knitwear, but old machines need to be reconfigured.

How to sew knitted fabrics on a regular sewing machine

How to sew knitwear without an opener on a household machine

Sewing machine needles for sewing knitwear

This article is structured in such a way as to give you an idea not only about knitwear machines, but also to advise how to sew knitwear on a regular Chaika-type straight-stitch machine. Therefore, carefully follow all the wizard’s advice; they are also suitable for ordinary machines.

For example, you should know that to sew knitwear you need to use special sewing needles. Often there is even a corresponding inscription on the box or packaging: JERSEY. This is the designation for knitted weave, on the basis of which modern stretchable fabrics are woven.

What stitch to sew knitwear

Let's move on to specifics. There are not many stitches that can “adapt” to knitwear. Select an option to use after the experiment.

- Straight stitch. When dealing with high elasticity, you can immediately forget about this type. Straight stitch looks good only if we talk about dense material. That is, 12% elongation coefficient. Usually it is cotton. And then, when sewing, do not forget to stretch the fabric by hand, otherwise the stitch will be unreliable. After all, even small changes in volume will lead to a rupture. But with stretching and low density, the stitch will turn out excellent.

- Zigzag stitch. This is ideal. It will be appropriate for any stretch ratio. The advantages are obvious - zigzags give the fabric “freedom” and do not fix the fabric as rigidly as possible. It is worth remembering that it is logical to use the minimum parameters. That is, select the minimum length and width from the available criteria on the machine. It’s also nice that you don’t need to stretch anything additional by hand. Work as is.

- Double method. Not a bad solution for an elastic material. The point is that the line is duplicated. The second will go next to the first, the distance according to the standard is only 3mm. Excess from the side should be carefully removed with scissors or a knife. The type of stitch itself also matters; it can be a straight technique or zigzags. It is more productive to use the second one. But for the sake of pure experimentation, try both options. In this case, a little tension during stitching will not be superfluous.

- Double needle. Almost every modern sewing equipment is equipped with this function. In fact, this is a duplication of the previous method, only in automatic mode. The smart machine will do everything for you.

- Stretch. Perhaps the best method of all those described above. From the name it is already clear that it is intended specifically for stretchy fabrics. Use it if such a function is available. But again, it is recommended to test all methods first.

Now we know how to properly sew knitwear on a simple sewing machine. As practice shows, an overlocker is not an indispensable piece of equipment. Of course, for a stitched edge it will be useful. But even overlock processing of a cut can be done on an old, proven machine, if you get used to it a little.

What is a cover (flat) seam?

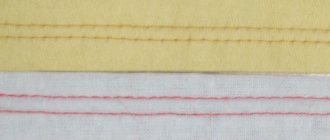

Many who are interested in sewing sooner or later ask themselves the question: What is a flat-stitch machine and what is the peculiarity of the so-called flat stitch (flatlock, flatstitch), or in everyday life - a cover stitch? This photo clearly shows what a 3-needle flat seam looks like on the product.

And this photo shows how a cover-stitch machine works: three needles and one lower looper. True, in industrial machines the looper can be on top and it is called a spreader. Then the cover seam will be “braided” (as in the photo above), but on both sides: on the wrong side and on the front side.

Now look at how a flat-stitch machine differs from an overlock machine. You can see that the overlocker has two loopers, and one of them extends beyond the needle plate, making it impossible to form a flat seam. That’s why overlockers can’t do anything else other than overcasting. And the function of simulating a flat seam with an overlock indicated in the instructions is just a type of overlock seam, rather an advertising gimmick that attracts your attention.

What else fundamentally distinguishes an overlocker from a cover stitcher, do you think? Of course, trimming the edges of the fabric using the built-in knives. Therefore, an overlocker is intended only for processing only the edges of the fabric, while a coverstitcher and a carpetlocker can lay a seam anywhere in the product. Accordingly, their sleeve reach (working surface) is larger.

How many needles are installed on knitting machines?

The number of needles used is determined by the number of threads. Depending on the operation, a knitted seam may contain 3, 4, 5 or even 8, 12 threads per stitch or more. True, more than 5 threads are already industrial models of cover-stitching machines, adapted strictly for one or two operations. For example, adding a wide elastic band to the waistband of sportswear.

This diagram shows how a stitch will be formed depending on the number of needles used on a cover stitch machine (from one to three).

Needles for sewing knitted fabrics

Standard needles, which are suitable for most other fabrics, can damage knitted fabric. As a rule, during the sewing process, a needlewoman may detect breaks or tightness in the stitching.

Needles for sewing knitwear.

Special needles with appropriate markings will help you avoid such moments:

- “Jersy” - suitable for wool and cotton knitwear.

- “Stretch” - a tool designed for synthetic fabric.

Jersey needles

The needles listed above have a more rounded point, which allows you to make a neat stitch without defects.

Needles for working with knitwear, like standard ones, differ in size. It is necessary to choose the length and thickness of the tool depending on the density of the web. When choosing a needle, you should adhere to the information indicated in the table.

| Density of fabric | Needle number |

| Thin knitwear (knitted stitch, waffle). | 70/9 |

| Medium density fabric (footer, ribbed, velor). | 80/11 |

| Dense and voluminous fabric (interlock, pique and capitonia and others). | 80/11, 90/14 |

Note! Before sewing knitted fabrics, it is first recommended to make a test stitch on a piece of fabric and adjust the thread tension.

What seams can a household cover sewing machine make?

You need to know all these technical details only in order to understand that it will not be possible to sew a knitted fabric well on a regular sewing machine. Even if the stitch is without gaps, it will be very fragile, because the threads (top and bottom) in the lockstitch line are very tight and when the seam stretches, they will definitely crack.

The same applies to overlockers without a differential feed, for example overlocker class 51. It may be possible to overcast the fabric, but you need to wear such clothes carefully, avoiding stretching the seams. This is precisely the property that knitted fabric is distinguished by - increased stretchability, which allows you to actively move in such clothing (sports), and often without ironing.

How to hem a T-shirt at the shoulders

Sewing a T-shirt at the shoulders is easy, since you don’t even have to rip the fabric.

Hemming steps:

- Mark the length you need from shoulder to collar;

- Draw a line with chalk or soap to the end of the armpit line.

- Fold the T-shirt in half.

- Trim off excess fabric.

- Pin the sleeve, front and back that you cut off.

- Sew these parts and press thoroughly.

Threads for the formation of high-quality knitted stitches

The most important condition for high-quality stitching when sewing knitwear, not only with special equipment (overlock, coverlock, cover stitch), but also with a regular machine, is thread. The quality of the stitch will depend on their thickness, strength, uniformity and elasticity.

Please note that for any sewing machine, when sewing knitted fabrics, it is recommended to use thin and elastic (synthetic) threads. It is strictly not recommended to thread thick but strong threads into knitted sewing machines. The effort to pull threads out of the loopers is so high that if the thread gets tangled, something can break.

It is also important to thread the threads correctly, approximately as shown in this photo. Such a “cunning” threading will dampen the looping of the thread, which will generally balance their tension in the stitching of an overlocker or cover stitch. In a conventional sewing machine, the twist of the thread (loop) can be suppressed if you use a linen elastic band; you just need to tie it around the sleeve of the machine and insert the thread (from the spool) under it while threading it.

What is the difference between knitted overlock

Sewing machines designed for knitted fabrics differ from others in the way they form a stitch. The stitch for sewing knitwear is formed using a looper and is called a chain stitch. The next photo on the left shows a knitted overlock “Merrylock 009”, on the right - a Janome flat-stitch machine.

On the left is a Janome sewing machine, on the right is a knitted overlocker

So, a sewing machine is threaded with two threads, one of which goes into the bobbin. The formation of a stitch occurs due to the interweaving of threads with each other. If you need to overcast the edge of a knitted product, then this can be done using a zigzag stitch and a special foot on a regular machine.

However, such a seam may not withstand much stretching, since both threads are strongly pulled together in the stitch. With an overlocker, this is practically impossible, since the overlock seam is quite elastic, stretchable and strong.

Installing the upper conveyor

In addition, the main differences between knitted overlockers include the presence of a differential conveyor. What is it? Example: while working on a simple sewing machine, you may encounter the fact that a strongly stretchy knitted fabric stretches and forms “waves”.

Note! Differential advancement of the fabric allows you to choose the degree of stretching or gathering of the fabric yourself. Modern models of sewing machines have special switches with which the fabric under the foot can be gathered or stretched.

What is the differential of an overlocker, coverlocker, or stitcher?

Well, the last thing you need to know about sewing machines for knitwear is to understand what a differential or differential type rack is. You can even find various articles on our website describing the operation of such a rail. But if you do not delve into the design features of this unit, you can explain its action using a simple example.

What do you do when you need to remove the fit from the top layer of fabric while sewing a garment? You push it under the paw with a fingernail or an awl. What do you do when, on the contrary, there is not enough top fabric? Well, of course, pull the top layer with your hand, trying to correct your own cutting mistake or poor operation of the sewing machine. Neither of these things improves the quality of your work, but that’s not about that now...

This is roughly how the differential rack works. In one case, it stretches the fabric during stitch formation (under the foot), in the other, it compresses. Both properties of the slats are used for various types of processing of knitted fabrics, as well as for making decorative stitches and seams (waves along the edge of the bottom of the skirt).

When buying an overlocker, it is important to pay attention to this, because the cheapest models of Chinese overlockers (3-4 thousand) or overlockers of older models do not have this function, which will make the processing of knitwear poor quality.

The lower handle in this photo controls the differential operation of the Janome ArtStyle 4057 overlocker.