Blind stitch seam

Sometimes, when hemming a dress or skirt, it is necessary to lay a decorative stitch along the hem, in accordance with the style of the product itself. But most often, when hemming the bottom of garments, especially those made of noble, natural fabrics, it is customary to hide the stitch connecting the hem and the main fabric.

Blindstitching is done by hand, but a sewing machine can also be used to make such a seam. The seam is not visible on the front side of the product; on the back side, a seam is laid, catching the thread in the needle to the thread of the main fabric.

Blind stitch made on a sewing machine

Hand stitching, called a “goat” stitch, is the easiest way to hem a dress by hand with a blind seam. You can hem knitwear by hand, just like fabric, in the same way or with an “over the edge” stitch. The thread tension is also done manually. The needle clings to the thread of the fabric below the fold with the seam back, is brought forward and clings to the thread of the fold also with the seam back. This “rapport” is repeated along the entire length of the product, attaching the fold to the main fabric. How to hem knitwear by hand

The threads must be selected so that the thickness of the hemming thread matches the thickness of the fabric thread, and the blind stitches do not stick out or tighten the fabric. This way the stitching will not be noticeable and the surface will be absolutely smooth on the front side.

The needle catches on the thread of the fabric

Using adhesive tape

This method is one of the easiest; it can be used even when you have absolutely no knowledge of any sewing technique. The adhesive tape itself comes in different widths, so you can find it in the same size as you want the width of the hem to be.

Glue it on the wrong side, iron it on the side of the paper tape, moving about a centimeter away from the edge of the folded fabric. After this, you need to remove the protective film from the paper, bend the hem to the desired length and iron again.

The excess fabric must then be carefully cut off. The seam will not be visible.

If the dress material is heavy textile, you will need two inserts.

Advantages of the method:

- The tape is suitable for fixing the hems of skirts, trousers, and coats.

- In fact, it is convenient and quick, and you can easily secure any hem.

Flaws:

- Professionals do not recommend using this option for securing the hem, believing that it increases the rigidity of the fabric, which will affect the appearance of the finished product. Since the glue has the property of hardening.

- The web is printed onto the face of the skirt fabric.

- Low quality cobwebs quickly lose their stickiness after just a few washes.

We offer you a two-minute video on how to properly glue the tape:

There are options for finishing the hem of the dress with and without hems.

- Godet skirt: pattern making, master class on how to sew a skirt with your own hands (from six wedges), fabric consumption

Necessary equipment

To create a blind seam manually use:

- Sewing thread,

- Sewing needle,

- Thimble,

- Chalk or a thin piece of soap,

- Ruler or pattern,

- Iron.

You may be interested in Sewing a quilted bedspread with your own hands

Spool of thread, needle and thimble

The thread should match the thickness of the fabric. Thick fabrics, wool, and suits are not hemmed with thin threads. For hemming silk, satin, and crepe de Chine, thin threads of the same composition are used. The same applies to needles; thick needles are used for dense fabrics, medium ones for suits, thin ones for silk and chintz.

For manual work, use a thimble, which will help protect your fingers from punctures and make it easier to work with the needle.

Chalk or soap is needed to draw fold lines on the fabric. To get a clear and thin line of the future fold, you need to sharpen the edges with soap or chalk.

Important! When steaming or ironing, soap will completely disappear from the fabric under the action of steam. It is better to use soap without fragrances. The chalk will need to be further cleaned.

When hemming a product using a machine, use special feet or separate attachments for a standard foot. The purpose of the nozzle is to prevent the needle from catching excess threads on the front side.

Blindstitch feet are included in the set of sewing machines, and working with them is described in detail in the instructions for use.

Blind stitch foot

Bottom hem.

Hi all!

The most common way to process the bottom of products is to hem them.

The hem of the bottom of the products is done using hem seams:

1. with open

2. or closed cuts.

In this case, the open cut on the hem can be processed in one of the ways to prevent fraying or not processed at all (according to the model), see below in the article.

Hem allowance.

The width of the hem allowance directly depends on the thickness of the material from which the clothing model is sewn and... on whether this product belongs to a particular seasonal group. For example:

- for winter coats, jackets, etc. an allowance of 4 - 5 - 6 cm wide is allocated for the hem;

- for raincoats, trench coats, light coats, parkas, etc. belonging to the demi-season or all-season groups, as well as for jackets, winter dresses, vests, jackets, etc. sewn from less thick materials than winter clothing, 3 - 4 - 5 cm are allocated;

- for blouses, blouses, shirts, sundresses, dressing gowns, skirts, tunics, etc. those sewn from medium materials are allocated 2 - 3 - 4 cm;

- for the same types of clothing, but sewn from thin, light materials, as for blouses that will be tucked into trousers or a skirt, an allowance of 1 - 1.5 cm is allocated;

(For hem seams with a closed cut, we are talking about the main hem allowance, which will be on the outside of the product on the wrong side).

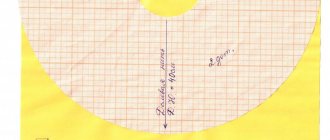

How to mark hem allowance?

In order to end up with a beautiful and even hem at the bottom of the product, you need to mark the hem allowance carefully and accurately. Moreover, this must be done “cleanly” along the entire length of the bottom of the product, no matter how long it may be.

You can use a variety of (store-bought or homemade) marking tools to draw lines for the bottom of the product,

and then “secure the result” with a hand-marked stitch using straight stitches.

Or choose another method and “draw” the lines directly with a sewing machine. We insert thin threads into the sewing machine that contrast with the main color tone of the product being sewn, set the stitch length to maximum, and set the tension of the upper thread to minimum.

For hem seams with an open cut, you only need one line,

but to make a hem seam with a closed cut - two.

(In today's article, the main character will be a hem seam with an open (treated or not) cut).

Hem the bottom with a closed hem seam.

Sometimes (according to the model) the hem is reinforced with adhesive cushioning materials (only before! processing the cut of the hem allowance).

This gives greater stability to the bottom of the item being sewn (for slippery, very flexible and moving materials). And it’s much easier to stitch a hem reinforced in this way.

How to reduce the thickness of the hem at intersecting seams?

When hemming is done in places where seams “flow” into the bottom line of the product: side, relief and middle back seam, significant “accumulations” of material occur. The allowances of intersecting seams “overlapping” on each other can make this place very thick and this will significantly complicate its further processing.

To avoid this, seam allowances in these areas should be trimmed. This can be done in several ways, but this procedure must be performed only inside the hem. (Up to the line of alignment of the hem cut with the product).

The shape of the bottom of the product.

The shape of the bottom of the product processed with a hem seam can be in three types:

Straight smooth edge.

Edge curved inwards

or out.

There are no problems with processing straight, even hems; it is done using one of the methods described below.

The inward curved bottom of the product is best processed by facing.

The one bent outwards needs to be gathered up.

How to remove excess fabric on hem?

Since there is a “whole heap” of information on how to remove excess fabric from the hem allowance, you will need to write a whole separate article about this sewing “procedure”. Read in the next publication “How to process the bottom of a sun skirt?”

Open hem hem.

Bottom hem with open raw cut.

On products made from woven thick and dense materials with non-fraying cuts, as well as from non-woven materials (natural and artificial leather, suede, etc.), the hem cut is not processed.

Bottom hem with open finished cut.

The hem allowance cut on items sewn from thick, loose and medium materials requires processing.

Methods for processing hem allowance cuts.

Processing the cut of the hem allowance with zigzag scissors.

On hem sections of products made from medium and thin dense materials, with practically non-fraying sections, it is possible to carve teeth along the cut.

Slightly more crumbling sections, with the same processing, cutting out the teeth can be slightly strengthened by laying a machine stitch with straight stitches under the carved section.

Hem sections can be overcast by hand:

Hand stitched with bias stitches.

Hand stitch with loop stitches.

Hand stitch with cross stitches like a goat or herringbone stitch.

(By the way, by hand stitching with cross stitches you can simultaneously process the cut of the hem and sew the hem to the product).

Processing with zigzag stitch.

The hem cut can be finished with a zigzag stitch.

No line

and with a line. (Straight stitches are sewn underneath the zigzag stitches for reinforcement.)

Zigzag stitches lie more evenly along the edge of the material if a strip of interlining or thin paper is placed under the edge of the fabric.

Processing the hem cut with tape or braid.

A hem cut treated with ribbon or braid looks very beautiful. Suitable for unlined products made from wool and silk fabrics of high product ranges.

On the hem allowance on the front side, using marking tools, at a distance from the cut equal to ½ the width of the tape used (or a little more or a little less), draw a line.

Laying one side of the tape against this line

We adjust it to the edge of the hem using a machine stitch to the edge.

The tape should cover the open cut of the hem allowance.

And then manually, using oblique stitches, we sew the ribbon, and along with it the hem, to the wrong side of the product.

If the threads used to perform such hand stitching are selected to match the color of the product and the required thickness, then such hand stitching will not be visible at all from the face of the product.

Cuts processed using the Hong Kong method.

The hem allowance cut can be finished with an open-cut edge stitch - the Hong Kong method. Edge width 3 mm.

This processing of the hem cut is suitable for products sewn from thick and medium fabrics, without lining.

You can read in detail about how slices are processed using the Hong Kong method by following the link to this article.

Cut edge.

Products sewn from thick and medium fabrics without lining, the cuts on their hem allowances can be processed with edging. The site milla-sidelnikova.com has a lot of material on processing cuts with binding, single-layer and double-layer bias. And if you set this goal, you can easily find all these materials on binding through the search bar of the site (top right).

Overlock.

The most famous and most common way to process a hem allowance cut is to process it with overlock stitches. But everything is simple here. You either have an overlocker or you don’t. No comments needed!

How is the hem secured to the wrong side of the product?

So, when all the necessary sewing manipulations with the hem allowance have been done, it’s time to secure the hem on the wrong side of the product. This can be done in several ways. We choose the appropriate one based on the stylistic features of the model being sewn.

- Nowadays, professional sewing machines that perform single-thread chain blind stitch are also becoming available to ordinary sewing enthusiasts. These are compact, small desktop devices. They are easy to set up and use, and do not require special skills. Used for hemming the bottom of products with a hidden stitch. However, for now, such machines are more likely to be found at small sewing enterprises, in ateliers, than in the home workshop of a simple sewing enthusiast. The price of the “unit” and the space in the house for such a machine are the main culprits for the massive absence of such tools in the life of every sewing enthusiast.

- The hem allowance can be sewn to the bottom of the product from the wrong side by hand, using a hidden hand stitch.

The thinner the threads (No. 120 -150), the more accurately the color of the threads is chosen, the less tight the stitches are, the less noticeable it will be on the finished product.

- The hem allowance can be sewn to the bottom of the product using a blind stitch on a sewing machine. (If, of course, your sewing machine has one in the set of stitches).

The more accurately the color of the thread is selected to match the main color tone of the product and the more successfully the thread tension of such a stitch is selected, the less noticeable it will be on the finished product.

- The hem allowance can be glued with textile glue. This method will be good for non-woven materials (leather, suede, raincoat fabric, varnish, etc.) The main thing is that the glue does not bleed onto the front side of the product and does not leave stains (this can be determined experimentally).

- Very specialized stores selling sewing accessories (sewing goods from only one, very well-known company) sell special double-sided adhesive tapes for gluing the hem of the bottom to the product (good for the skin).

- The hem of the bottom can be secured on the wrong side with adhesive web. Good for light to medium fabrics.

- The hem can be sewn onto the product with a line or several lines (according to the model).

This can be a very narrow stitch - stitching to the edge

or wider (according to model). There can be one line

two

and more (according to model).

Securing the hem allowance by stitching it in is the most common way to process the bottom of products.

A line (two, three) can be made with threads that match the tone of the product being sewn or be related and contrasting to it and sharply contrasting (according to the model). The length of the stitches, the thickness and texture of the threads are selected to suit the style of each specific model.

It is better to carry out the stitching by laying it on the front side of the product.

There are some nuances in the “behavior” of hems at cuts, at hems, at vents and at the corners of sewn products. But since there are a lot of types of all these parts, we will deal with the hemming of each of them separately, as we “go through” the corresponding material.

Hemming of the bottom at the cuts, at the hems, at the flaps.

Hem the bottom at the vent.

Well, it seems that’s all I wanted to say about hemming the bottom with an open-cut seam.

Good luck! Sincerely, Milla Sidelnikova!

Methods for hemming a product

There are several simple and popular ways to finish the bottom of a garment, including how to blindstitch a skirt by hand. Each of the methods is used when working with certain fabrics, styles and forms the hem of the product.

Note! It is recommended to make test samples if possible, make changes if necessary, and only then proceed to processing the bottom of the product.

Double hem

A double hem as an option for processing the bottom is made with a closed seam in the fold, which gives the product a neat appearance from the wrong side. It is used when working with fabrics of different densities and weaves, from thin to suiting.

- The front side of the bottom of the product is turned over to the wrong side by 1-2 cm and ironed.

- The fold is once again turned over to the wrong side by the amount of the hem, from 3 to 7 cm depending on the cut, style and other parameters, and ironed.

Then it is hemmed with a hidden stitch or manually with a goat stitch.

Double hem by hand

Hemming with hemmed facing

The tailored facing completely follows the curves of the product and makes it possible to create unique models. These can be cutouts at the neckline, armholes, slits at the bottom. Open seams are finished with a trimmed facing.

You might be interested in: Making patterns and sewing covers for sewing machines

The facing is cut out, exactly repeating the cut that will be processed. Sewn to the edges using a machine. The facing is then turned over to the wrong side and hand sewn with a blind stitch.

Hemming with cut edge

Original models with trims made from edging tape or with the possibility of double-sided wearing are processed using the cut edging method. The edging tape or trimmed strip of fabric is folded with the wrong side inward and ironed. The front side of the tape or strip is applied to the front side of the product so that the open cuts are on one side. The tape is stitched and turned down and to the wrong side. On the reverse side, the open cut is folded over and manually hemmed with a blind seam.

Hemming the cut with edging

How to correctly mark the bottom line of a product

Before marking the bottom line in a product with a free pattern, preliminary preparation for this operation is necessary. The product should be ironed well, the length should be determined, and the shoes should be prepared. The length is determined by measuring the segment from the floor to the bottom of the product. The segment must be the same length. A mark is applied to the fabric, and subsequently the marks will be connected into a single fold line.

Important! A skirt, dress or robe cut along an oblique line requires special care when preparing for measurements. Seams and darts must be perfectly ironed. Check the side seams for distortion.

Checked fabric requires a different approach: at the time of cutting, you should take into account the size of the check, its “rapport” and decide on the length.

We hem different types of skirts

Before you start hemming your clothes, prepare your skirt and all the necessary equipment. To work you will need:

- threads;

- needle;

- chalk pencil or small piece of soap;

- scissors;

- ruler;

- sewing pins or safety needles;

- iron.

The scissors must be sharp, so you can cut the fabric evenly and accurately, and the edge will turn out beautiful and even.

How to prepare a skirt:

- Put on your skirt and decide on the length you want. Pay attention to the waist, where you expect it to be. Use a chalk pencil to mark the length you have chosen.

- Remove the product, turn it inside out, place it on a flat surface and smooth it out.

- From the mark, retreat 3-4 cm for the hem height and 1 cm for the double hem.

- If there is a single hem, then simply retreat 3-4 cm. If there is no hem, leave 5 mm for the stitching.

- Use a ruler to draw a cutting line.

- Trim off the excess length using scissors.

Knitted skirt

Skirts made of knitted fabric are comfortable and practical to wear, they do not wrinkle, keep you warm in winter, and the summer version is highly breathable. The structure of knitted fabric is elastic and elastic. But due to the fact that it stretches and does not lie flat, it is difficult to hem it. Firstly, not every seam is suitable for such material, and secondly, old-style sewing machines are not capable of sewing knitwear. Therefore, craftsmen offer three types of hemming:

- line “Goat”;

- overlock processing;

- single hem.

Line “Goat”:

- Prepare the skirt by cutting off the excess length.

- Make a hem of 3-4 cm and iron. Secure with thread or pins.

- Start sewing from the seam of the skirt to hide the knot of thread unnoticed. You should move from left to right, but the needle step goes from right to left.

- Insert the needle above the hem, grabbing 1-2 threads from the product itself.

- Next, taking a step to the right, grab a few threads at the hem itself.

- Continuing to move to the right, repeat steps 4 and 5.

- As a result, the drawing should look like a cross.

You can study in more detail in the video.

Processing with an overlock is considered the easiest way to hem; if there is none, you can stitch it with a machine using the “Zigzag” function:

- Prepare the skirt, leaving 5 mm from the desired length.

- Finish the edge with an overlocker, starting from the seam of the skirt.

- When processing, do not pull the fabric; it should slide easily.

Single hem:

- Turn the product inside out, place it on a flat surface, and smooth it out.

- Step back from the desired length to 3-4 cm. This will be the height of the hem.

- Finish the edge with overlock or zigzag.

- Make a hem and iron.

- Secure the hem with sewing pins or baste with thread.

- Sew with an even seam, retreating from the edge to the width of the sewing machine foot.

If the knitwear is dense, you can make two parallel lines.

Cotton skirt

Cotton fabric is well suited for summer, it is light, comfortable to wear, the only negative is that it wrinkles a lot. However, cotton material is pliable and can be easily manipulated. For this type of fabric, a “double hem” seam is suitable:

- Mark the required length on the product.

- Turn it inside out, use a ruler to mark 3-4 cm for the hem and 1 cm for the hem.

- Cut off the excess fabric, make the first hem of 1 cm, and iron.

- Make a second hem and iron again.

- If you doubt that you will sew smoothly, secure with thread.

- Machine sew an even seam parallel to the edge of the skirt.

You can study in more detail in the video.

Also for cotton fabric, a “single hem” seam is suitable, it is described above.

Chiffon skirt

Chiffon is a light, flowing material that is suitable for both formal and casual wear. Long skirts look especially good from it. The downside of this fabric is that it frays; sewing it requires skill and patience. You can process the edge in three ways:

- blind stitches by hand;

- Moscow seam;

- finishing the edge with bias tape.

Blind stitches by hand:

- Finish the hem with an overlock or zigzag stitch.

- Make a hem and iron.

- Baste with thread or safety needles.

- Starting from the seam of the skirt, insert the needle and secure the thread.

- Hook 2 threads of the product itself with a needle above the hem

- Next, taking a step forward, insert the needle into the hem itself, where the overlock processing was done.

- Repeat steps 5 and 6.

Video:

When sewing by hand, do not tighten the thread too much so that the fabric lies evenly and does not wrinkle.

The point of a hidden seam is that the thread will not be visible from the front side. A product stitched in this way looks beautiful and neat.

Moscow seam:

- Prepare the edge of the product by cutting to the required length. Leave an allowance of 3-4 mm.

- Set the stitch width on the machine to no more than 2 mm.

- Fold the edge once and secure with thread or pins.

- Stepping back 1 mm from the edge, sew with an even stitch, starting from the seam of the product.

- When finished, use scissors to carefully trim off the excess allowance that remains after stitching.

Video:

Finishing the edge with bias tape:

- Turn the skirt inside out, mark 5 mm from the required length.

- Take the bias tape and apply it to the edge of the hem, placing the fabric inside the tape.

- Secure with pins and sew with an even seam.

- Iron at the end.

Fixing the hem with a web

The adhesive tape in the form of a web makes it easier to form the bottom of the garment. The ribbon is placed inside the hem, as close to the cut as possible. The cut must be processed. Using an iron heated to a temperature appropriate for the type of fabric, iron the hem. The hem is secured with pins or thread.

Important! Do not iron the adhesive tape several times. Overheating the ribbon will cause the fabric and hemline to deform.

Processing the bottom with adhesive web

Hem seal

Suit and dress fabrics in the hem area are compacted with duplicating fabric to achieve an ideal smooth surface on the front side. To do this, the duplicating fabric is secured on the wrong side of the product along the fold line of the hem. The hem is turned to the wrong side and hemmed.

Using the techniques described above, you can carefully decorate the bottom of the finished product. The final operation of tailoring creates the final appearance, emphasizes the style and shapes the image. Properly selected threads and tools will help you complete this job efficiently.