Home / Natural fabrics

Back

Published: 01/20/2021

Reading time: 3 min

0

138

It is difficult to imagine hygiene procedures, an evening shower or a traditional trip to the bathhouse without a warm towel: cozy terry cloth has forever entered the everyday life of every person. It is loved by generations, given to each other for holidays, and all attempts to replace it with synthetic analogues are doomed to failure.

- 1 External and qualitative features of the material

- 2 How and from what it is made

- 3 Varieties

- 4 Pros and cons

- 5 Use of terry cloth

- 6 Tips for choosing quality products

- 7 Rules of care

- 8 Conclusion

External and qualitative features of the material

Everyone knows embossed, soft, pleasantly springy under the hand - frote, terry or terry cloth. Its name is believed to come from a vulgarized form of the French frottèe (erased, rubbed), but there is no linguistic evidence.

It is unknown who and when first made this material. Most likely, this happened in Europe in the days after the industrial revolution, when huge weaving factories appeared. Before this, historical and literary sources had not mentioned fluffy towels.

History of origin and popularization of fabric

There are several versions of the appearance of frote. According to one of them, India is considered the homeland. Another theory says that matter first appeared in Turkey. This is confirmed by the external resemblance of the material to carpet. But carpets were woven in India, Pakistan, and Uzbekistan. It would be correct to say that the birthplace of cotton is also the birthplace of terry, since it is from natural cotton that this looped fabric is made. The product took on a more modern and familiar appearance in the 18th century, when textile factories producing cotton fabric appeared. The massive demand for fabrics created the need for large quantities of raw materials.

Looped terry

Cotton began to be sown in the southern regions of the Russian Empire, Egypt, China, and the USA. In Russia, cotton gradually pushed linen into second place. The technology for producing terry fabric was not a state secret, like silk. Many countries around the world have successfully used it. The fluffy soft material has become universally popular.

As in many areas, there is innovation in the textile industry - terry fabric made from bamboo fibers is gaining popularity. The raw material grows in tropical and subtropical climates, and crushed stems and leaves are used to make fibers.

Bamboo terry

How and from what it is made

Terry fabric is traditionally made from natural fibers - cotton, less often with the addition of flax. However, the trend of the last decade for additives has led to the emergence of mixed compositions with bamboo and synthetic additives, mainly polyester.

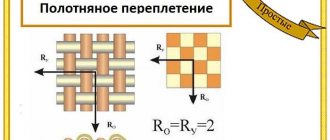

At the enterprise, the fabric is woven with twill (less often plain) weave, but with a weakened warp, from which loops are pulled on the front or both sides. It turns out that, depending on the production method, terry can be either one-sided or two-sided.

Cheaper fabric remains looped, since the base is not touched. On material of a higher class, the pile is cut, lightly trimmed, and polished. This can be done figuratively, resulting in a jacquard or printed pattern.

Types and their properties

Terry fabric is produced in a huge variety. Materials differ in composition, external design, and density. We list the main types:

- Regular looped terry . The one-sided material familiar to everyone, which is used for sewing towels. Comfortable, does not require complex care, pleasant to the body, cotton, but can be linen or bamboo, as well as with a small percentage of synthetics.

- High-tech terry with membrane . A modern fabric that combines two different textiles - frote and an excellent moisture-absorbing membrane. Suitable for wet cleaning of premises, washing windows, etc. Another name is waterproof terry. This variety has a higher percentage of synthetics.

- Terry with double-sided pile . A fabric familiar to many, differing only in that the loops are located both on the front side and on the back. The properties are the same: hygroscopic, environmentally friendly, hygienic. The composition is the same as that of ordinary one-sided terry cloths.

- Knitted . Sometimes the warp is not woven, but knitted, then we are talking about knitted terry. However, this is no longer the classic textile material that was invented in India. This also includes backcombed terry, which has a soft backcomb on the inside.

In addition to the listed types of terry fabrics, there are others. For example, with longer pile, which makes the material more comfortable and soft.

There is cut and uncut terry. The first loops are cut off and look like hairs. The second one has classic loops.

The material is often used for cleaning premises. The scraps remaining after production or torn terry are used for flooring and household rags. They absorb moisture well and remove dirt well. Terry rags are often used in hospitals, children's institutions, and catering establishments. It is as hygienic and environmentally friendly as possible.

Varieties

Historically, a great variety of types of terry cloth have been formed, and besides, technologists develop new ones almost every year.

The main indicators by which it is classified:

- density;

- pile height;

- twisting of threads.

To improve the absorbency of the material, the raw material - that is, cotton threads - is additionally twisted, and a thick thread is twisted from several thin ones. The finished product is a little rougher, but it performs its functions at the highest level.

The best towel fabric is with the thickest pile, double-sided, with a tight twist of the threads.

Not long ago, terry-waterproof terry appeared: a one-sided material to which a synthetic (PA or PVC) membrane is glued on the backside. The material is considered a godsend for the furniture industry.

Main characteristics

The main characteristics of the material are the following indicators:

- The degree of twist of the thread - the more twisted the thread, the higher the quality indicator of the fabric.

- Density - indicators can be completely different, their range is from 250 to 800 g/m2. Low-density fabric (250-300 g/m2) is usually thin and light; it is made with a high synthetic content. The average density (350-500 g/m2) of the most popular and widely used variety of terry. It absorbs water well and is easy to use. High-density fabric (above 550 g/m2) is very heavy, bulky, and quite expensive. Density determines the degree of fluffiness, since the weight of the fabric per square meter depends on the number of loops.

- Pile height is also an important indicator of fluffiness. A short pile will be hard and rough, while a long pile will give the fabric softness. The optimal pile size is 5 mm.

An important characteristic of the material is its ability to absorb moisture. High density, long and well-twisted pile increase this ability, but give it a lot of weight.

Pile on terry cloth

Advantages and disadvantages

The advantages of the material are determined by its composition and texture: terry is dense, warm and comfortable, because it is natural. Thanks to the loops, it absorbs more than its weight, does not electrify and easily massages the skin. Good quality terry products can withstand several hundred automatic spin washes!

Pros:

- hygroscopicity;

- hygiene;

- softness;

- breathability;

- hypoallergenic.

Against the backdrop of amazing consumer characteristics, minor disadvantages are lost: terry cloth is inelastic, easily “injured,” takes a long time to dry, and is very heavy when wet.

Author:

Anastasia Kukushkina

I hope you enjoy the article I have prepared for you! If you find errors in it, write to me about it! I will answer any questions you have, ask them!